Question

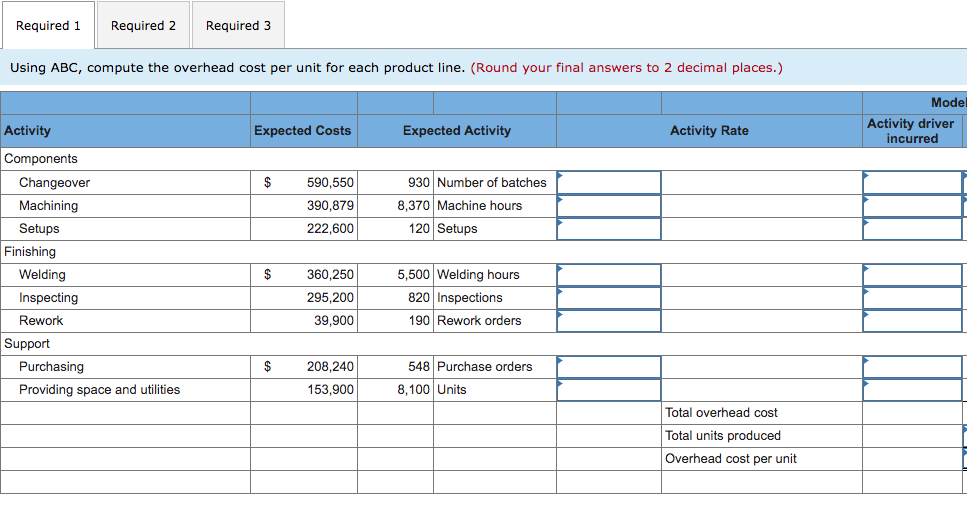

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in its components department. The mechanical systems are combined with

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in its components department. The mechanical systems are combined with the housing assembly in its finishing department. The activities, costs, and drivers associated with these two manufacturing processes and the production support process follow.

| Process | Activity | Overhead Cost | Driver | Quantity | ||||

| Components | Changeover | $ | 590,550 | Number of batches | 930 | |||

| Machining | 390,879 | Machine hours | 8,370 | |||||

| Setups | 222,600 | Number of setups | 120 | |||||

| $ | 1,204,029 | |||||||

| Finishing | Welding | $ | 360,250 | Welding hours | 5,500 | |||

| Inspecting | 295,200 | Number of inspections | 820 | |||||

| Rework | 39,900 | Rework orders | 190 | |||||

| $ | 695,350 | |||||||

| Support | Purchasing | $ | 208,240 | Purchase orders | 548 | |||

| Providing space | 30,800 | Number of units | 8,100 | |||||

| Providing utilities | 123,100 | Number of units | 8,100 | |||||

| $ | 362,140 | |||||||

Additional production information concerning its two product lines follows.

| Model 145 | Model 212 | |||||

| Units produced | 2,700 | 5,400 | ||||

| Welding hours | 2,200 | 3,300 | ||||

| Batches | 465 | 465 | ||||

| Number of inspections | 470 | 350 | ||||

| Machine hours | 3,050 | 5,320 | ||||

| Setups | 60 | 60 | ||||

| Rework orders | 110 | 80 | ||||

| Purchase orders | 365 | 183 | ||||

Required: 1. Using ABC, compute the overhead cost per unit for each product line. 2. Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $190 for Model 145 and $113 for Model 212. 3. If the market price for Model 145 is $588.81 and the market price for Model 212 is $333.12, determine the profit or loss per unit for each model.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started