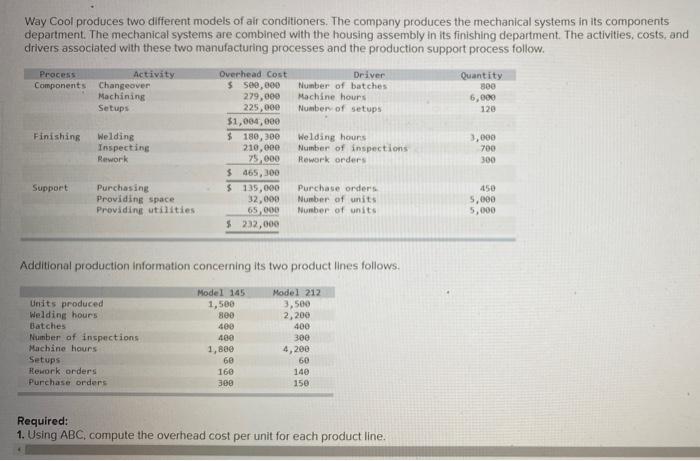

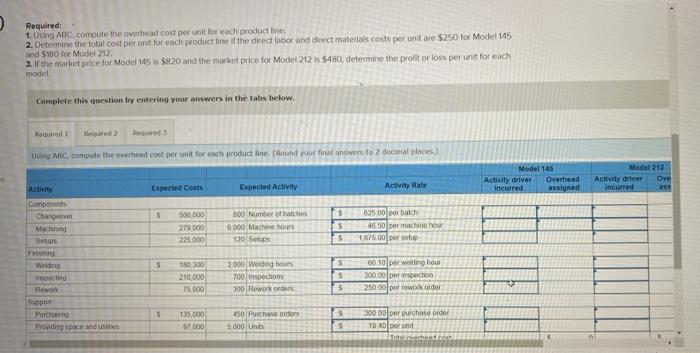

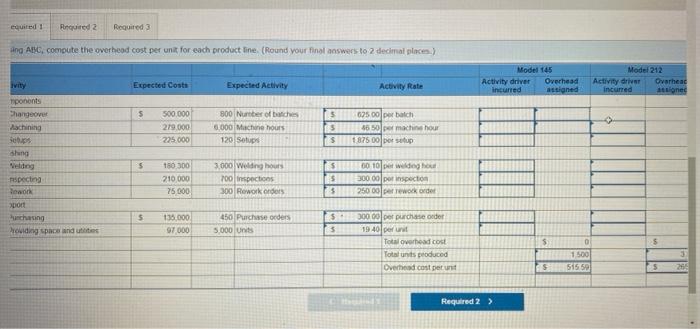

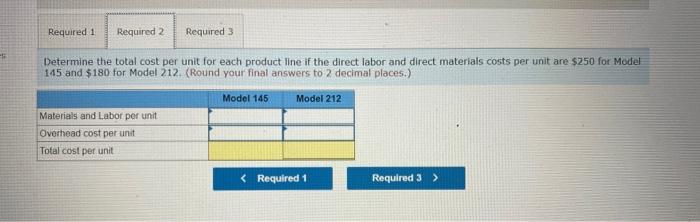

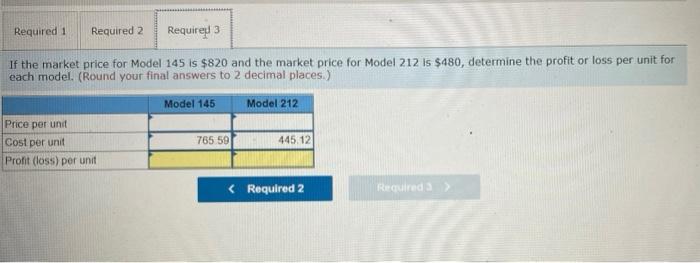

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in its components department. The mechanical systems are combined with the housing assembly in its finishing department . The activities, costs, and drivers associated with these two manufacturing processes and the production support process follow. Process Activity Overhead Cost Driver Quantity Components Changeover $ see, 000 Number of batches 800 Machining 279,000 Machine hours 6,000 Setups 225,000 Number of setups 120 $1,004,000 Finishing Welding $ 180, 300 Welding hours 3,000 Inspecting 210,000 Number of inspections 700 Rework 75,000 Rework orders 300 $ 465,300 Support Purchasing $ 135,000 Purchase orders 450 Providing space 32,000 Number of units 5,000 Providing utilities 65,000 Number of units 5,000 $ 232,000 Additional production Information concerning its two product lines follows. Units produced Welding hours Batches Number of inspections Machine hours Setups Rework orders Purchase orders Model 145 1,500 800 400 400 1,800 60 160 300 Model 212 3,500 2,200 400 300 4,200 60 140 150 Required: 1. Using ABC, compute the overhead cost per unit for each product line. Required: 1. Using ABC, compute the overhead cost per unit for each product line 2. Determine the total cost per unit for each product line of the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212 3. in the market price for Model 165 $820 and the market price for Model 212 6 $480. determine the profit or loss per unit for each model Complete this question by entering your answers in the tabs below. Required 2 Recured U ABC, compute the overhead cost per unit for each product line (Hound your final answers to 2 decimal places) Model 145 Activity driver Overhead incurred assigned Model 212 Activity driver Ove incurred 253 Expected Costs Acovity Rate Expected Activity 5 500.000 279.000 235 000 300 Number of batches 6000 Machine hours 120 Serie 5 5 5 625.00 per bal 46,50 per machine bo 187500 perso Act Combo Change Machining Sebas Fishing Welding poco Ruws Support Pro Providing space and stes 5 180 300 210,000 75,000 3.000 Welding hours 700 inspections 300 Rowok orders 5 $ 5 60.10 per welding hour 30000 perspection 250.00 porowok order 5 5 135.000 000 450 Purchase orders 5000 Unts 200.00 per purchase order 10.0 port cuted 1 Required 2 Required 3 ang AC, compute the overhead cost per unit for each product line. (Round your final answers to 2 decimal places) Model 212 Activity driver Overhead incurred onec Expected Costa Expected Activity Model 145 Activity driver Overhead incurred assigned Activity Rate $ 500.000 279.000 225.000 800 Number of the 6.000 Machine hours 120 Setup S 5 $ 60500 perbach 650 per machine hour 1875 00 per setup vity mponents Phangeover Aachining soups shing Welding Rspecting Book port chasing houding space and this 5 150 300 210 000 75 000 3.000 Welding hours 700 Inspections 300 Rework onders S 5 $ 0010 per wedghout 300.00 por inspection 250 per rework ordet 5 $. 135.000 97 000 450 Purchase orders 5.000 Unt 5 300.00 per purchase order 19:40perunt Total overhead cost Total units produced Overhead cost per un $ 0 1500 51550 5 261 Required 2 > Required 1 Required 2 Required 3 - Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212. (Round your final answers to 2 decimal places.) Model 145 Model 212 Materials and Labor por unit Overhead cost per unit Total cost per unit Required 1 Required 2 Required 3 If the market price for Model 145 is $820 and the market price for Model 212 Is $480, determine the profit or loss per unit for each model. (Round your final answers to 2 decimal places.) Model 145 Model 212 Price per unit Cost per unit Profit (loss) per unit 765.59 445.12