Answered step by step

Verified Expert Solution

Question

1 Approved Answer

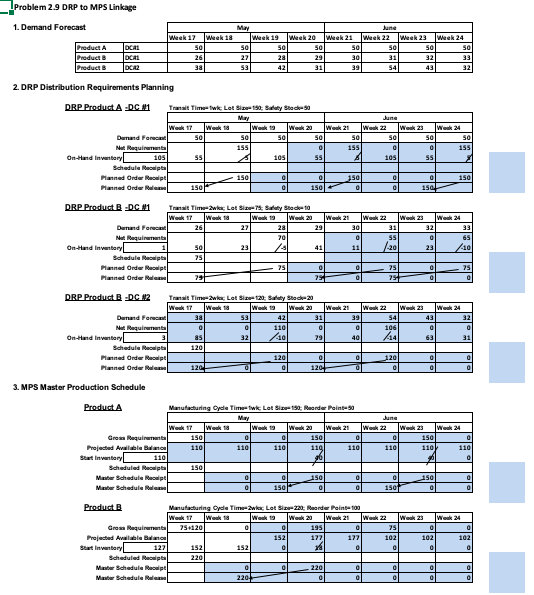

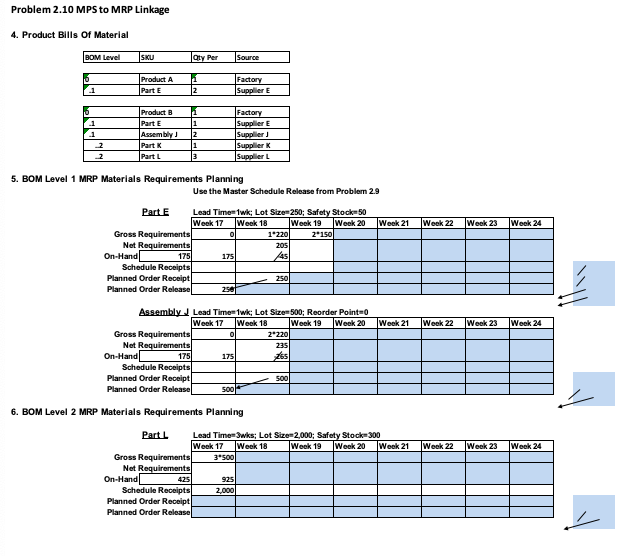

We have to use Master Schedule release from problem 2.9 The solution for problem 2.9 is added above the problem 2.10 Problem 2.9 DRP to

We have to use Master Schedule release from problem 2.9

The solution for problem 2.9 is added above the problem 2.10

Problem 2.9 DRP to MPS Linkage 1. Demand Forecast Product Product Products OCAL OCAL DCRZ May June Week 17 Week 18 Week 19 Week 20 Week 21 Week 22 Week 23 Week 24 50 50 501 50 50 50 50 50 26 27 30 31 32 33 38 53 31 39 54 32 2. DRP Distribution Requirements Planning DRP Product ADC #1 Transit Time Iwk Lot 150 y Stock May Juna Wakt Wet Work 19 Wek 20 W21 Wek 22 Wok 23 Wok 24 Durand Forest 50 50 50 50 50 50 50 50 Nu equirement 155 0 155 0 0 155 On-Hand Inventory 105 55 105 55 61 105 SS Schedule Rosta Hanned Order Now 150 0 0 150 0 0 150 Panned Order Now 150 0 150 0 150 DRP Product DC 11 Transit Timow Lot Sizes: Sady Stede-10 West wa Wok 19 Wok 20 Work 21 Wek 22 w23 Wok 24 Durand For 26 27 28 29 30 31 32 33 Mat Requirement 70 0 55 0 65 On-Hand Inventory 50 23 41 11 -20 23 4-10 Schedule Roupa 75 Panned Order Now 75 01 - 781 75 Planned Order me 791 75 0 754 0 0 DRP Product DC 12 Trans Time2wix: Lot Sip120 Sty Steck-20 Iw Weka Wok 19 W 20 W 21 Wok 22 Wok 23 Werk24 Dund For 38 53 42 31 39 54 43 32 Nat Requirements 0 0 110 0 0 106 0 0 On-Hund Inventory 85 32 710 79 40 63 31 Schedule to 120 Planned Order op! 120 0 0 120 0 0 Panned Order 1201 0 120 0 0 3. MPS Master Production Schedule Product Manufacturing Ode Time Iwk Let S 150: Reader Paint 50 May June Werk 17 Wek 18 Work 19 We 20 Week 21 Work 22 Work 23 Wek 24 Grosa Mequirements 150 0 150 0 0 150 0 Prejected Available dance 110 110 110 119 110 110 110 Start Inventory 110 0 Scheduled opta 150 Mit Schedule 0 150 ol 0 150 0 Mit Schedule 150 0 1507 0 110) 0 Product B Manufacturing Ode Time2wix: Lot Sipe=220: Murder Point 100 Wosk 17 Werk 18 Wok 19 W 20 Wek 21 Wok 22 We 23 Work 24 Gres Requirement 75120 0 o 195 o 75 0 Projected Available Bano 152 177 172 102 102 102 Start Inventory 1271 152 152 0 v 0 0 Scheduled Meta 220 Mit Schedule Rope 0 220 01 Mit Schedule 2207 0 0 0 0 Problem 2.10 MPS to MRP Linkage 4. Product Bills Of Material IBOM Level SKU aty Per Source 16 Product A Part E 11 2 Factory Supplier E 1 16 1 1 1 Product B Part Assembly Part K PartL 1 12 1 13 Factory Supplier E Supplier Supplier K Supplier 2 5. BOM Level 1 MRP Materials Requirements Planning Use the Master Schedule Release from Problern 2.9 Week 21 Week 22 Week 23 Week 24 Part E Lead Time Iwk; Lot Size 250; Safety Stock-50 Week 17 Week 18 Week 19 Week 20 Gross Requirements o 1220 20150 Net Requirements 205 On-Hand 175 175 445 Schedule Receipts Planned Order Receipt 250 Planned Order Release 2set Week 21 Week 22 Week 23 Week 24 Assembly J Lead Time Iwk; Lot Size 500; Reorder Point=0 Week 17 Week 18 Week 19 Week 20 Gross Requirements 0 2220 Net Requirements 235 On-Hand. 175 175 Schedule Receipts Planned Order Receipt 500 Planned Order Release Sool 6. BOM Level 2 MRP Materials Requirements Planning Week 22 Week 23 Week 24 Part L Lead Time-3wks; Lot Size=2,000; Safety Stock-300 Week 17 Week 18 Wei 18 Week 20 Week 21 Gross Requirements 3*500 Net Requirements On-Hand 425 925 Schedule Receipts 2,000 Planned Order Receipt Planned Order Release Problem 2.9 DRP to MPS Linkage 1. Demand Forecast Product Product Products OCAL OCAL DCRZ May June Week 17 Week 18 Week 19 Week 20 Week 21 Week 22 Week 23 Week 24 50 50 501 50 50 50 50 50 26 27 30 31 32 33 38 53 31 39 54 32 2. DRP Distribution Requirements Planning DRP Product ADC #1 Transit Time Iwk Lot 150 y Stock May Juna Wakt Wet Work 19 Wek 20 W21 Wek 22 Wok 23 Wok 24 Durand Forest 50 50 50 50 50 50 50 50 Nu equirement 155 0 155 0 0 155 On-Hand Inventory 105 55 105 55 61 105 SS Schedule Rosta Hanned Order Now 150 0 0 150 0 0 150 Panned Order Now 150 0 150 0 150 DRP Product DC 11 Transit Timow Lot Sizes: Sady Stede-10 West wa Wok 19 Wok 20 Work 21 Wek 22 w23 Wok 24 Durand For 26 27 28 29 30 31 32 33 Mat Requirement 70 0 55 0 65 On-Hand Inventory 50 23 41 11 -20 23 4-10 Schedule Roupa 75 Panned Order Now 75 01 - 781 75 Planned Order me 791 75 0 754 0 0 DRP Product DC 12 Trans Time2wix: Lot Sip120 Sty Steck-20 Iw Weka Wok 19 W 20 W 21 Wok 22 Wok 23 Werk24 Dund For 38 53 42 31 39 54 43 32 Nat Requirements 0 0 110 0 0 106 0 0 On-Hund Inventory 85 32 710 79 40 63 31 Schedule to 120 Planned Order op! 120 0 0 120 0 0 Panned Order 1201 0 120 0 0 3. MPS Master Production Schedule Product Manufacturing Ode Time Iwk Let S 150: Reader Paint 50 May June Werk 17 Wek 18 Work 19 We 20 Week 21 Work 22 Work 23 Wek 24 Grosa Mequirements 150 0 150 0 0 150 0 Prejected Available dance 110 110 110 119 110 110 110 Start Inventory 110 0 Scheduled opta 150 Mit Schedule 0 150 ol 0 150 0 Mit Schedule 150 0 1507 0 110) 0 Product B Manufacturing Ode Time2wix: Lot Sipe=220: Murder Point 100 Wosk 17 Werk 18 Wok 19 W 20 Wek 21 Wok 22 We 23 Work 24 Gres Requirement 75120 0 o 195 o 75 0 Projected Available Bano 152 177 172 102 102 102 Start Inventory 1271 152 152 0 v 0 0 Scheduled Meta 220 Mit Schedule Rope 0 220 01 Mit Schedule 2207 0 0 0 0 Problem 2.10 MPS to MRP Linkage 4. Product Bills Of Material IBOM Level SKU aty Per Source 16 Product A Part E 11 2 Factory Supplier E 1 16 1 1 1 Product B Part Assembly Part K PartL 1 12 1 13 Factory Supplier E Supplier Supplier K Supplier 2 5. BOM Level 1 MRP Materials Requirements Planning Use the Master Schedule Release from Problern 2.9 Week 21 Week 22 Week 23 Week 24 Part E Lead Time Iwk; Lot Size 250; Safety Stock-50 Week 17 Week 18 Week 19 Week 20 Gross Requirements o 1220 20150 Net Requirements 205 On-Hand 175 175 445 Schedule Receipts Planned Order Receipt 250 Planned Order Release 2set Week 21 Week 22 Week 23 Week 24 Assembly J Lead Time Iwk; Lot Size 500; Reorder Point=0 Week 17 Week 18 Week 19 Week 20 Gross Requirements 0 2220 Net Requirements 235 On-Hand. 175 175 Schedule Receipts Planned Order Receipt 500 Planned Order Release Sool 6. BOM Level 2 MRP Materials Requirements Planning Week 22 Week 23 Week 24 Part L Lead Time-3wks; Lot Size=2,000; Safety Stock-300 Week 17 Week 18 Wei 18 Week 20 Week 21 Gross Requirements 3*500 Net Requirements On-Hand 425 925 Schedule Receipts 2,000 Planned Order Receipt Planned Order ReleaseStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started