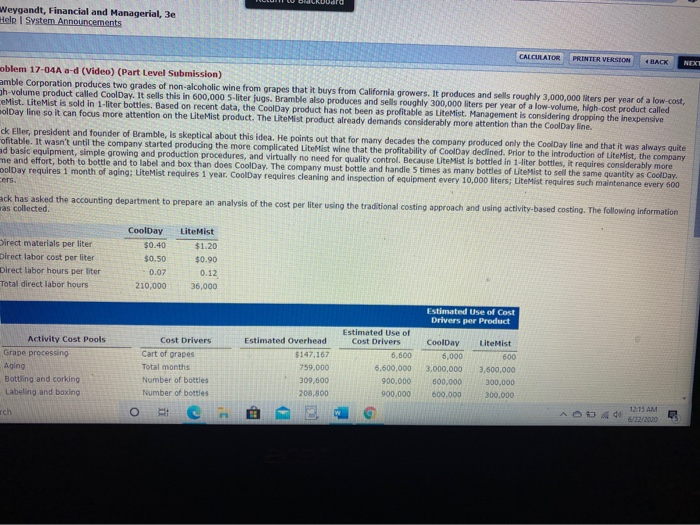

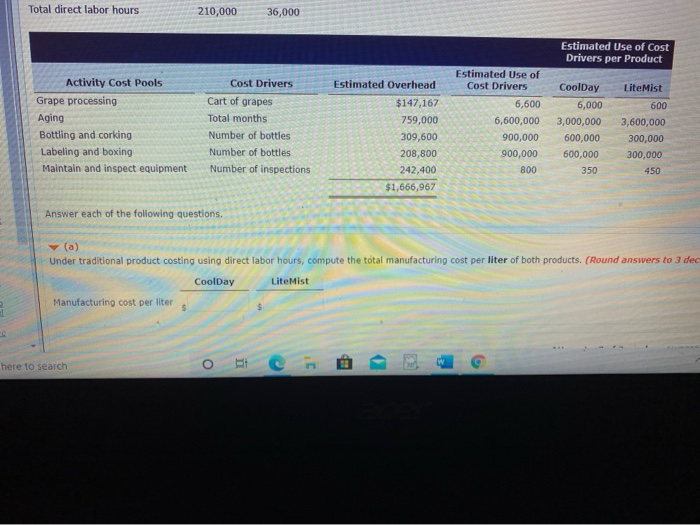

Weygandt, Financial and Managerial, 3e Help System Announcements CALCULATOR PRINTER VERSION 4 BACK NEXI oblem 17-04A a-d (Video) (Part Level Submission) amble Corporation produces two grades of non-alcoholic wine from grapes that it buys from California growers. It produces and sells roughly 3,000,000 liters per year of a low-cost, Gh-volume product called CoolDay. It sells this in 600,000 5-liter jugs. Bramble also produces and sells roughly 300,000 liters per year of a low volume, high-cost product called emist. Lite Mist is sold in 1-liter bottles. Based on recent data, the CoolDay product has not been as profitable as Lite Mist. Management is considering dropping the inexpensive olDay line so it can focus more attention on the LiteMist product. The Lite Mist product already demands considerably more attention than the CoolDay line. ck Eller, president and founder of Bramble, Is skeptical about this idea. He points out that for many decades the company produced only the CoolDay line and that it was always quite ofitable. It wasn't until the company started producing the more complicated UteMist wine that the profitability of CoolDay declined. Prior to the introduction of Lite Mist, the company ad basic equipment, simple growing and production procedures, and virtually no need for quality control. Because Ute Mist is bottled in 1-liter bottles, it requires considerably more me and effort, both to bottle and to label and box than does CoolDay. The company must bottle and handle 5 times as many bottles of Lite Mist to sell the same quantity as CoolDay. moolDay requires 1 month of aging; Lite Mist requires 1 year. CoolDay requires cleaning and inspection of equipment every 10,000 liters; Lite Mist requires such maintenance every 600 cers. ack has asked the accounting department to prepare an analysis of the cost per liter using the traditional costing approach and using activity-based costing. The following information as collected. irect materials per liter Direct labor cost per liter Direct labor hours per liter Total direct labor hours CoolDay $0.40 $0.50 -0.07 210,000 Lite Mist $1.20 $0.90 0.12 36,000 Estimated Use of Cost Drivers per Product Activity Cost Pools Grape processing Aging Bottling and corking Labeling and boxing Cost Drivers Cart of grapes Total months Number of bottles Number of bottles Estimated Overhead $147,167 759.000 309,000 208,800 Estimated Use of Cost Drivers 6.600 6.500.000 900,000 900.000 CoolDay 6,000 3,000,000 600,000 600.000 Lite Mist 600 3,600,000 300,000 300,000 rch O B 12:15 AM 6/22/2020 Total direct labor hours 210,000 36,000 Estimated Use of Cost Drivers per Product Cost Drivers Lite Mist Activity Cost Pools Grape processing Aging Bottling and corking Labeling and boxing Maintain and inspect equipment Cart of grapes Total months Number of bottles Number of bottles Number of inspections Estimated Overhead $147,167 759,000 309,600 208,800 242,400 $1,666,967 Estimated Use of Cost Drivers 6,600 6,600,000 900,000 900,000 800 CoolDay 6,000 3,000,000 600,000 600,000 350 600 3,600,000 300,000 300,000 450 Answer each of the following questions, Under traditional product costing using direct labor hours, compute the total manufacturing cost per liter of both products. (Round answers to 3 dec CoolDay Lite Mist Manufacturing cost per liter 5 o B here to search