Answered step by step

Verified Expert Solution

Question

1 Approved Answer

What is the decision that Shanti has to make? What are the reasons she has to make this decision now? What are the issues in

What is the decision that Shanti has to make? What are the reasons she has to make this decision now?

What are the issues in the operations area of the company? What could be the cause of operations problems?

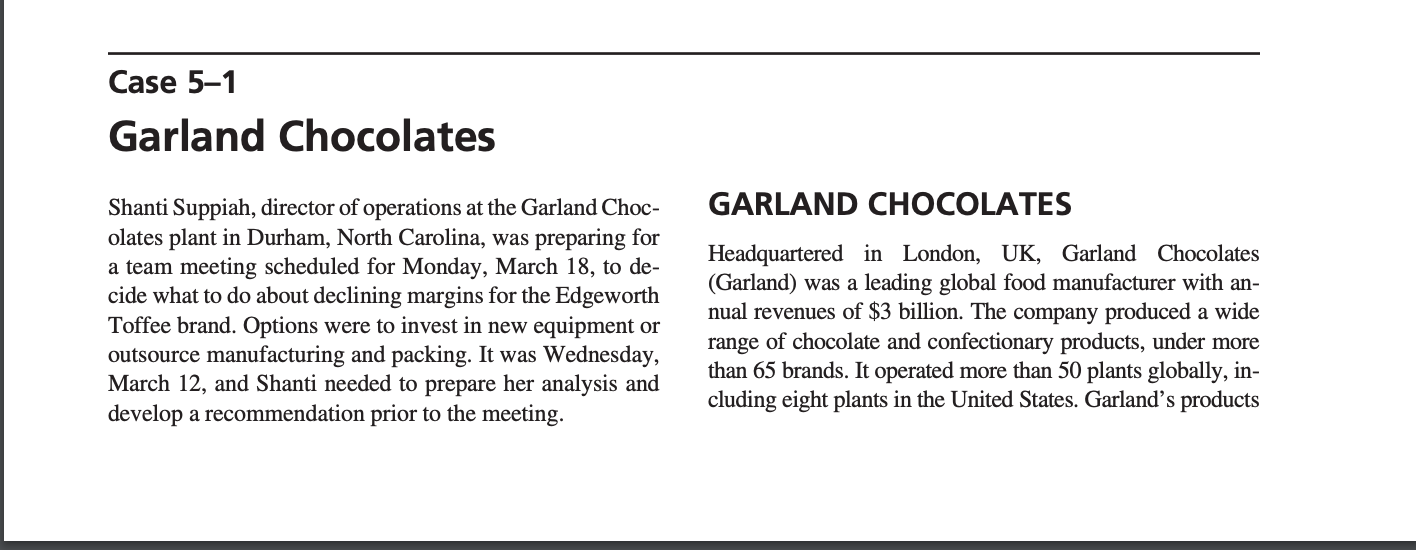

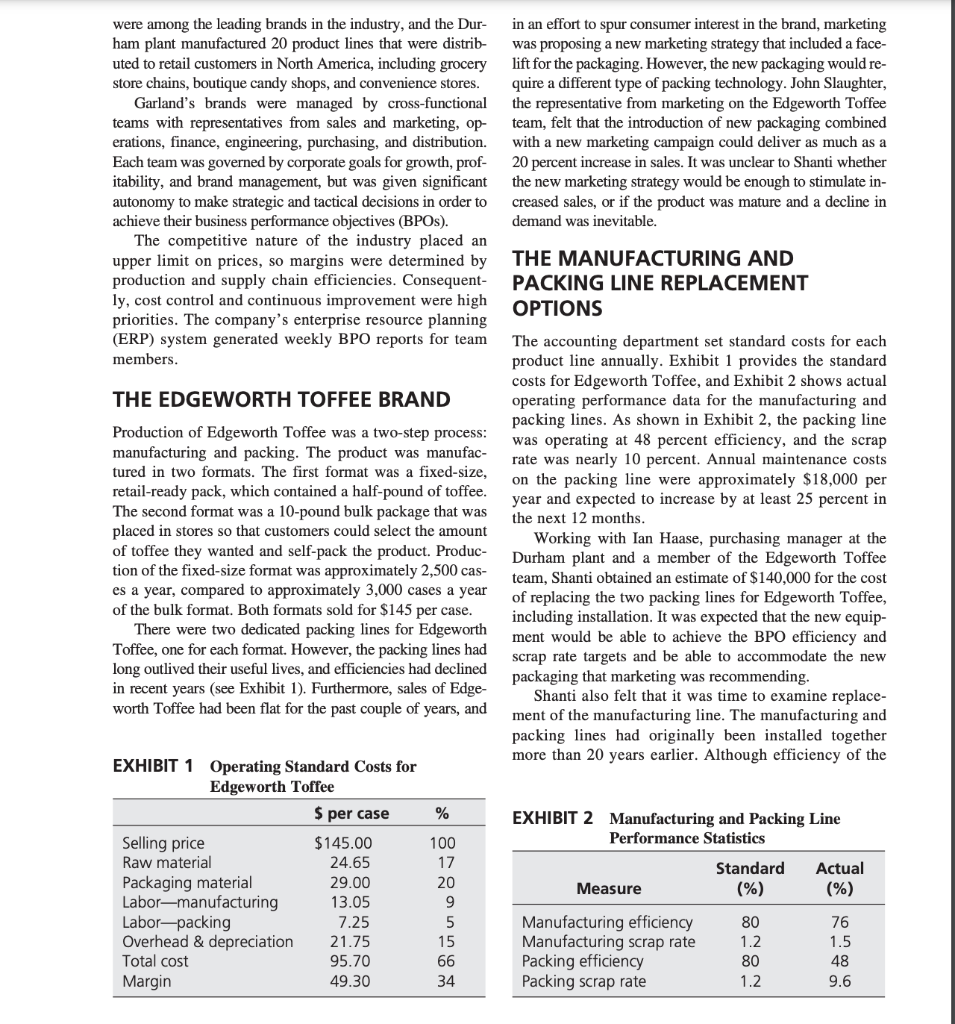

Shanti Suppiah, director of operations at the Garland Choc- GARLAND CHOCOLATES olates plant in Durham, North Carolina, was preparing for a team meeting scheduled for Monday, March 18, to de- Headquartered in London, UK, Garland Chocolates cide what to do about declining margins for the Edgeworth (Garland) was a leading global food manufacturer with anToffee brand. Options were to invest in new equipment or nual revenues of $3 billion. The company produced a wide outsource manufacturing and packing. It was Wednesday, range of chocolate and confectionary products, under more March 12 , and Shanti needed to prepare her analysis and than 65 brands. It operated more than 50 plants globally, indevelop a recommendation prior to the meeting. cluding eight plants in the United States. Garland's products were among the leading brands in the industry, and the Dur- in an effort to spur consumer interest in the brand, marketing ham plant manufactured 20 product lines that were distrib- was proposing a new marketing strategy that included a faceuted to retail customers in North America, including grocery lift for the packaging. However, the new packaging would restore chains, boutique candy shops, and convenience stores. quire a different type of packing technology. John Slaughter, Garland's brands were managed by cross-functional the representative from marketing on the Edgeworth Toffee teams with representatives from sales and marketing, op- team, felt that the introduction of new packaging combined erations, finance, engineering, purchasing, and distribution. with a new marketing campaign could deliver as much as a Each team was governed by corporate goals for growth, prof- 20 percent increase in sales. It was unclear to Shanti whether itability, and brand management, but was given significant the new marketing strategy would be enough to stimulate inautonomy to make strategic and tactical decisions in order to creased sales, or if the product was mature and a decline in achieve their business performance objectives (BPOs). demand was inevitable. The competitive nature of the industry placed an upper limit on prices, so margins were determined by THE MANUFACTURING AND production and supply chain efficiencies. Consequent- PACKING LINE REPLACEMENT ly, cost control and continuous improvement were high OPTIONS priorities. The company's enterprise resource planning (ERP) system generated weekly BPO reports for team The accounting department set standard costs for each members. product line annually. Exhibit 1 provides the standard custs for Edgeworth Toffee, and Exhibit 2 shows actual operating performance data for the manufacturing and Production of Edgeworth Toffee was a two-step process: packing lines. As shown in Exhibit 2, the packing line manufacturing and packing. The product was manufac- was operating at 48 percent efficiency, and the scrap tured in two formats. The first format was a fixed-size, ras nearly 10 percent. Annual maintenance costs retail-ready pack, which contained a half-pound of toffee, on the packing line were approximately $18,000 per The second format was a 10-pound bulk package that was year and expected to increase by at least 25 percent in placed in stores so the next 12 months. of toffee they wanted Working with Ian Haase, purchasing manager at the tion of the fixed-size Dorham plant and a member of the Edgeworth Toffee es a year compare team, Shanti obtained an estimate of $140,000 for the cost of replacing the two packing lines for Edgeworth Toffee, of the bulk format. Both formats sold for $145 per case. including installation. It was expected that the new equipThere were two dedicated packing lines for Edgeworth ment would be able to achieve the BPO efficiency and Toffee, one for each format. However, the packing lines had scrap rate targets and be able to accommodate the new long outlived their useful lives, and efficiencies had declined packaging that marketing was recommending. in recent years (see Exhibit 1). Furthermore, sales of Edge- Shanti also felt that it was time to examine replaceworth Toffee had been flat for the past couple of years, and ment of the manufacturing line. The manufacturing and packing lines had originally been installed together EXHIBIT 1 Operating Standard Costs for more than 20 years earlier. Although efficiency of the Edgeworth Toffee EXHIBIT 2 Manufacturing and Packing Line Performance Statistics manufacturing line was close to the target of 80 per- that it would need six months to ramp up production of Edgecent, it was also showing signs of deterioration. The ef- worth Toffee. ficiency rate had declined to 76 percent, compared to more than 90 percent five years prior, and it had become THE TEAM MEETING increasingly more difficult to find replacement parts. A new manufacturing line would cost approximately As Shanti looked at the information on her laptop that $600,000 installed. had been collected regarding manufacturing and packing of Edgeworth Toffee, she knew that something had to be OUTSOURCING done to address the declining margins of the brand as a result of increased production costs. Investing in new equip- In addition to investigating options to replace the existing ment seemed like an obvious solution; however, the capital manufacturing and packing lines, Shanti had also looked investment would be significant and her proposal would into outsourcing. A preliminary review indicated that there need to exceed the company's 10 percent cost of capital would be substantial coordination costs if only packing rate to get approval by finance. was outsourced; therefore, outsourcing manufacturing and While reviewing the proposal by Martin, Shanti felt that packing was investigated. Ian and Shanti selected two con- some of the overhead costs at the Durham plant could be elimtract manufacturers to submit proposals, Martin Contract inated if production of Edgeworth Toffee was outsourced. Manufacturing (Martin) and Dasari Inc. Bids were requested The estimate provided by the accounting department was that from both for the existing packaging and the new pack- overhead costs allocated to the brand could be reduced by apaging proposed by marketing. In order to make sure the proximately 30 percent if production was outsourced. suppliers were well informed about the manufacturing and Historically, the company's strategy had been to packing processes, both were invited to tour the Durham control production of its products to ensure quality and plant, and they were provided with detailed information delivery performance. Garland had an excellent reputaand related data regarding the operation of the lines. tion with it customers and the customer service level Following a review of the proposals submitted by the for Edgeworth Toffee was a line fill rate of 98 percent. suppliers, Ian and Shanti decided that Martin had the best However, if the case to outsource could be made sucbid. Martin quoted a cost of $68.00 for manufacturing and cessfully to the team on Monday, Shanti felt that senior packing for both the current packaging and marketing's management would approve the proposal. This was an new packaging. The supplier would be responsible for raw important decision and she wanted to make a clear recmaterial and packaging material costs. In addition, Garland ommendation at the meeting on Monday, supported by a would pay $35,000 in tooling costs up front. Martin indicated thorough analysis of both optionsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started