Question

What is the total variance in the actual and static budget What is the direct material volume variance Is this direct material volume variance favorable

What is the total variance in the actual and static budget

What is the direct material volume variance

Is this direct material volume variance favorable or unfavorable

What is the direct material efficiency variance

What is the direct material price variance

Is the direct material price variance favorable or unfavorable

What is the volume variance in fixed overhead

Is the volume variance in fixed overhead favorable or unfavorable

What is the sum (net) of all the price, efficiency and volume variances across all the variable accounts (material, labor, variable overhead)

What is the actual cost per unit produced

What is the transfer price per frame? (Remember that the transfer price is the standard cost per unit.)

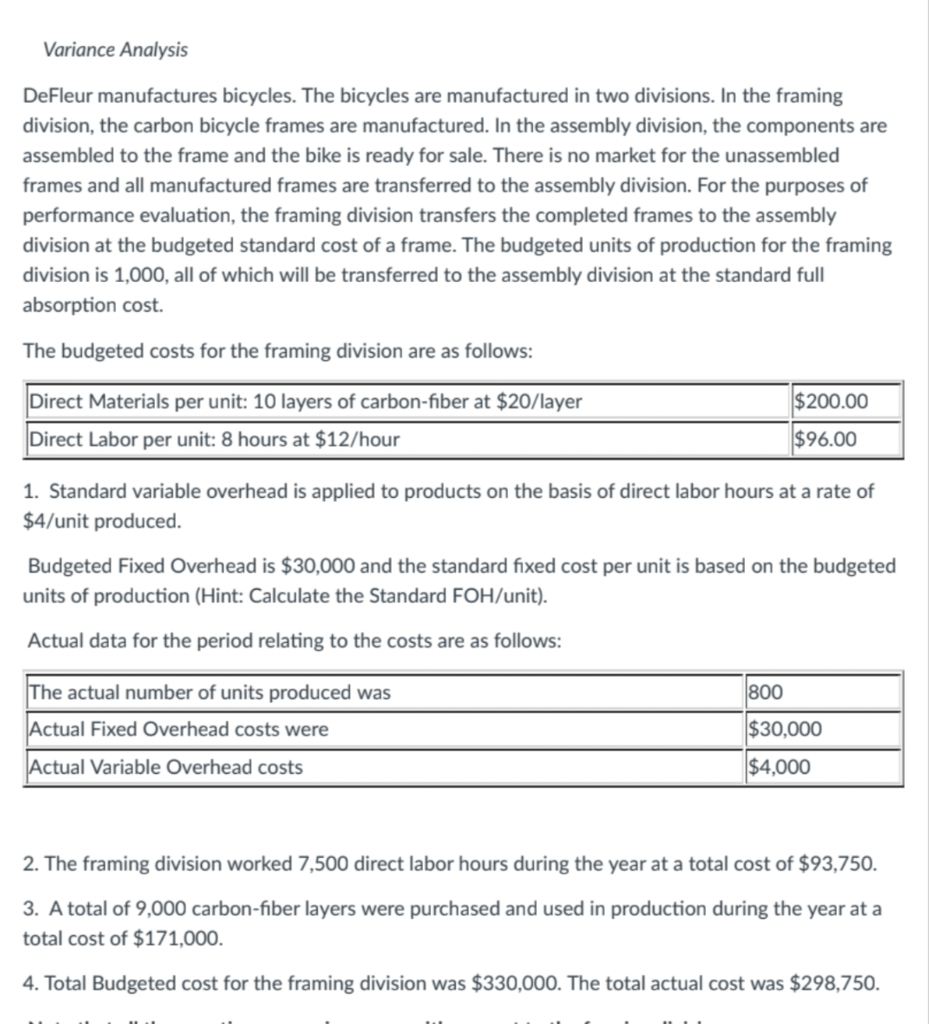

Variance Analysis DeFleur manufactures bicycles. The bicycles are manufactured in two divisions. In the framing division, the carbon bicycle frames are manufactured. In the assembly division, the components are assembled to the frame and the bike is ready for sale. There is no market for the unassembled frames and all manufactured frames are transferred to the assembly division. For the purposes of performance evaluation, the framing division transfers the completed frames to the assembly division at the budgeted standard cost of a frame. The budgeted units of production for the framing division is 1,000 , all of which will be transferred to the assembly division at the standard full absorption cost. The budgeted costs for the framing division are as follows: 1. Standard variable overhead is applied to products on the basis of direct labor hours at a rate of $4/ unit produced. Budgeted Fixed Overhead is $30,000 and the standard fixed cost per unit is based on the budgeted units of production (Hint: Calculate the Standard FOH/ unit). Actual data for the period relating to the costs are as follows: 2. The framing division worked 7,500 direct labor hours during the year at a total cost of $93,750. 3. A total of 9,000 carbon-fiber layers were purchased and used in production during the year at a total cost of $171,000. 4. Total Budgeted cost for the framing division was $330,000. The total actual cost was $298,750

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started