Will give you good comments if you can make it detailed and answer my question. Software engineers required

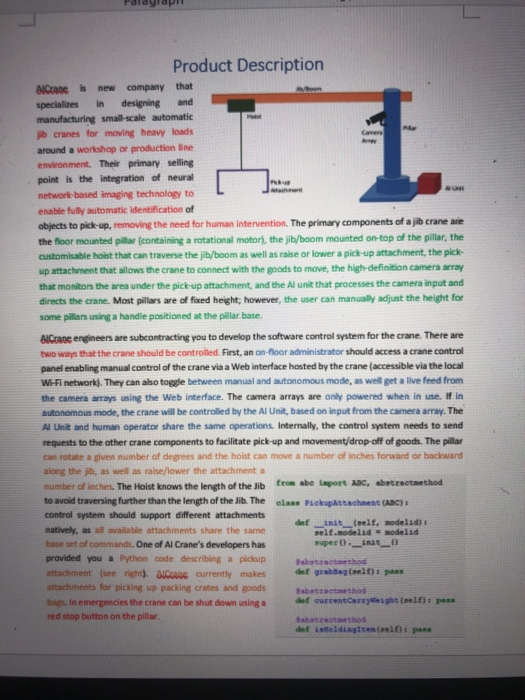

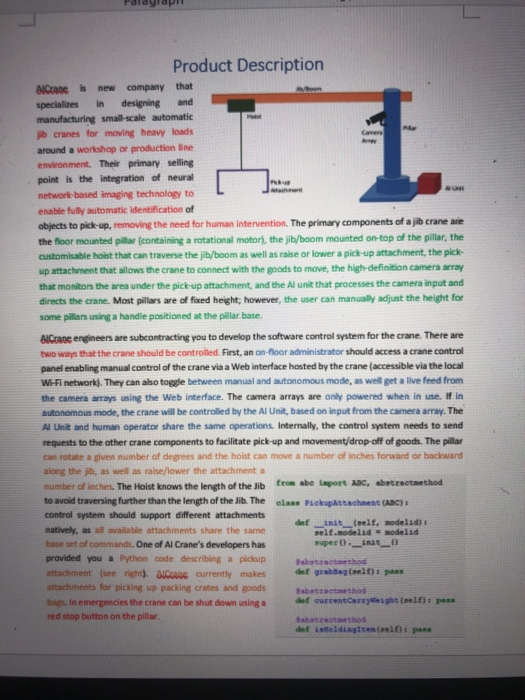

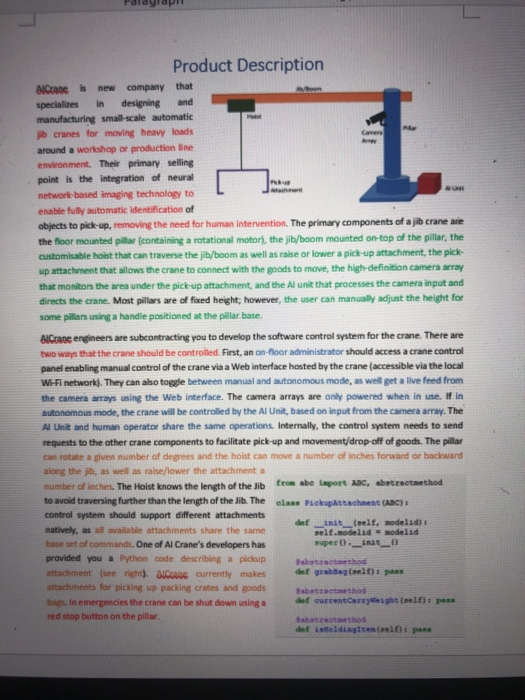

Product Description AlCaDe s new company that specializes in designing and manufacturing small-scale automatic jb cranes for moving heavy loads around a workshop or production Sine environment. Their primary selling point is the integration of neural network-based imaging technology to enable fully automatic identification of objects to pick-up, removing the need for human intervention. The primary components of a jib crane aide the floor mounted pillar (containing a rotational motor), the jib/boom mounted on-top of the pillar, the customisable hoist that can traverse the jib/boom as well as raise or lower a pick-up attachment, the pick- up attachment that allows the crane to connect with the goods to move, the high-definition camera array that monitors the area under the pick-up attachment, and the Al unit that processes the camera input and directs the crane. Mast pillars are of fixed height, however, the user can manually adjust the height for some pillars using a handle positioned at the pillar base. Cane AlCrane engineers are subcontracting vou to develop the software control system for the crane. There are two ways that the crane should be controlled.First, an on-floor administrator should access a crane control panel enabling manual control of the crane via a Web interface hosted by the crane (accessible via the local Wi-Fi networkj. They can abo toggle between manual and autonomous mode, as well get a live feed from the camera arrays using the Web interface. The camera arrays are only powered when in use. If in autonomous mode, the crane will be controlled by the Al Unit, based on input from the camera array. The Al Unit and human operator share the same operations Internally, the control system needs to send requests to the other crane components to facilitate pick-up and movement/drop-off of goods. The pillar can rotate a given number of degrees and the hoist can move a number of inches forward or backward along the j, as well as raise/lower the attachment a number of inches. The Hoist knows the length of the lib fron abe Laport ADC, abetractnethod to avoid traversing further than the length of the Jib. The elass Plokupkttachnent (Ac) contral system should support different attachmentst eeit, modelid) natively, as all available attachments share the same base set of commands. One of Al Crane's developers has pravided you a Python code describing a pickup elf modelid Babrtractaethod attachment (see right). aucase currently makes det grabbaginnlf)s pass attachments for picking up packing crates and goods bags. In emergencies the crane can be shut down using adef currentCarryeight (relf): pas red stop button on the pillar abatrsctaethod Paragraph [6 marks] 8. Design a class stracture (present your solution as a class diagram) that represents the data for a single request made by the control system to grab an item using the pick-up attachment. Your solution should include examples of inheritance, abrtract classes or nefaces, and aggregation or composition Hint The class diagram should show the crane control that contains the different components (pillar, hoist and pick-up attachment), support for different types of pick-up attachment (packing crate vs. goods bag), and the representation for the two types of pillar (basic and adjustable). Product Description AlCaDe s new company that specializes in designing and manufacturing small-scale automatic jb cranes for moving heavy loads around a workshop or production Sine environment. Their primary selling point is the integration of neural network-based imaging technology to enable fully automatic identification of objects to pick-up, removing the need for human intervention. The primary components of a jib crane aide the floor mounted pillar (containing a rotational motor), the jib/boom mounted on-top of the pillar, the customisable hoist that can traverse the jib/boom as well as raise or lower a pick-up attachment, the pick- up attachment that allows the crane to connect with the goods to move, the high-definition camera array that monitors the area under the pick-up attachment, and the Al unit that processes the camera input and directs the crane. Mast pillars are of fixed height, however, the user can manually adjust the height for some pillars using a handle positioned at the pillar base. Cane AlCrane engineers are subcontracting vou to develop the software control system for the crane. There are two ways that the crane should be controlled.First, an on-floor administrator should access a crane control panel enabling manual control of the crane via a Web interface hosted by the crane (accessible via the local Wi-Fi networkj. They can abo toggle between manual and autonomous mode, as well get a live feed from the camera arrays using the Web interface. The camera arrays are only powered when in use. If in autonomous mode, the crane will be controlled by the Al Unit, based on input from the camera array. The Al Unit and human operator share the same operations Internally, the control system needs to send requests to the other crane components to facilitate pick-up and movement/drop-off of goods. The pillar can rotate a given number of degrees and the hoist can move a number of inches forward or backward along the j, as well as raise/lower the attachment a number of inches. The Hoist knows the length of the lib fron abe Laport ADC, abetractnethod to avoid traversing further than the length of the Jib. The elass Plokupkttachnent (Ac) contral system should support different attachmentst eeit, modelid) natively, as all available attachments share the same base set of commands. One of Al Crane's developers has pravided you a Python code describing a pickup elf modelid Babrtractaethod attachment (see right). aucase currently makes det grabbaginnlf)s pass attachments for picking up packing crates and goods bags. In emergencies the crane can be shut down using adef currentCarryeight (relf): pas red stop button on the pillar abatrsctaethod Paragraph [6 marks] 8. Design a class stracture (present your solution as a class diagram) that represents the data for a single request made by the control system to grab an item using the pick-up attachment. Your solution should include examples of inheritance, abrtract classes or nefaces, and aggregation or composition Hint The class diagram should show the crane control that contains the different components (pillar, hoist and pick-up attachment), support for different types of pick-up attachment (packing crate vs. goods bag), and the representation for the two types of pillar (basic and adjustable)