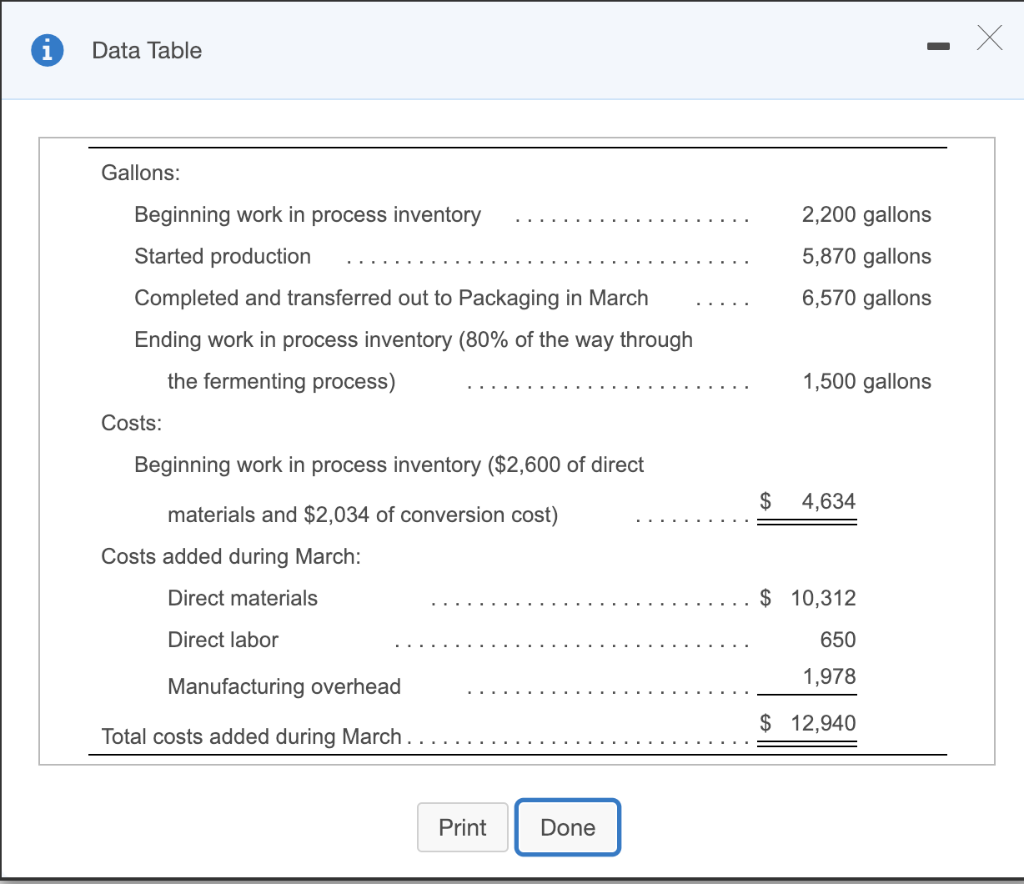

Winery in Newton comma MassachusettsNewton, Massachusetts , has two departments: Fermenting and Packaging. Direct materials are added at the beginning of the fermenting process (grapes) and at the end of the packaging process (bottles). Conversion costs are added evenly throughout each process. Data from the month of MarchMarch for the Fermenting Department are as follows:

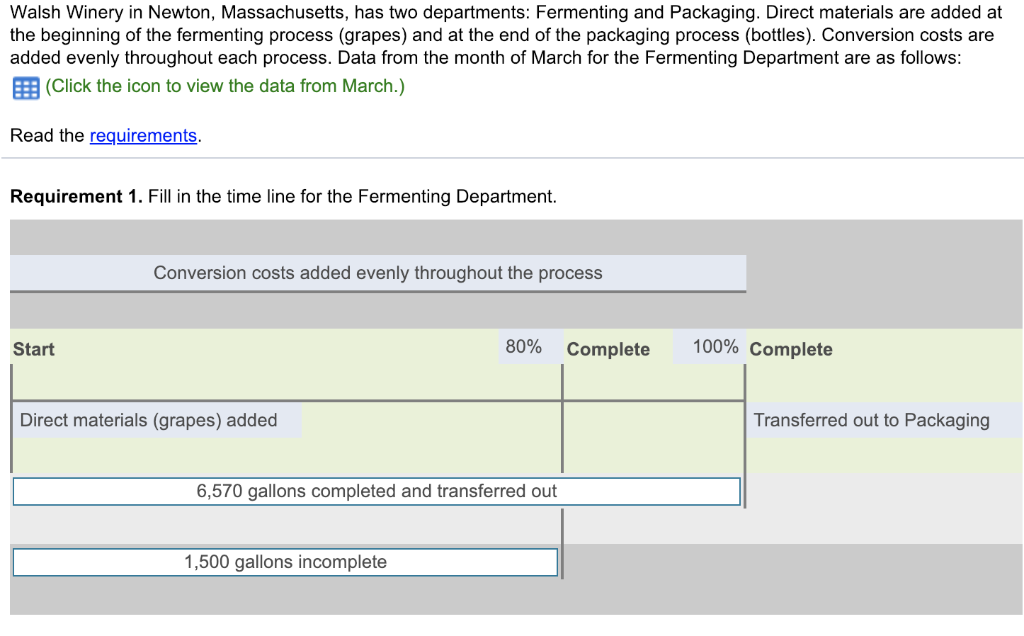

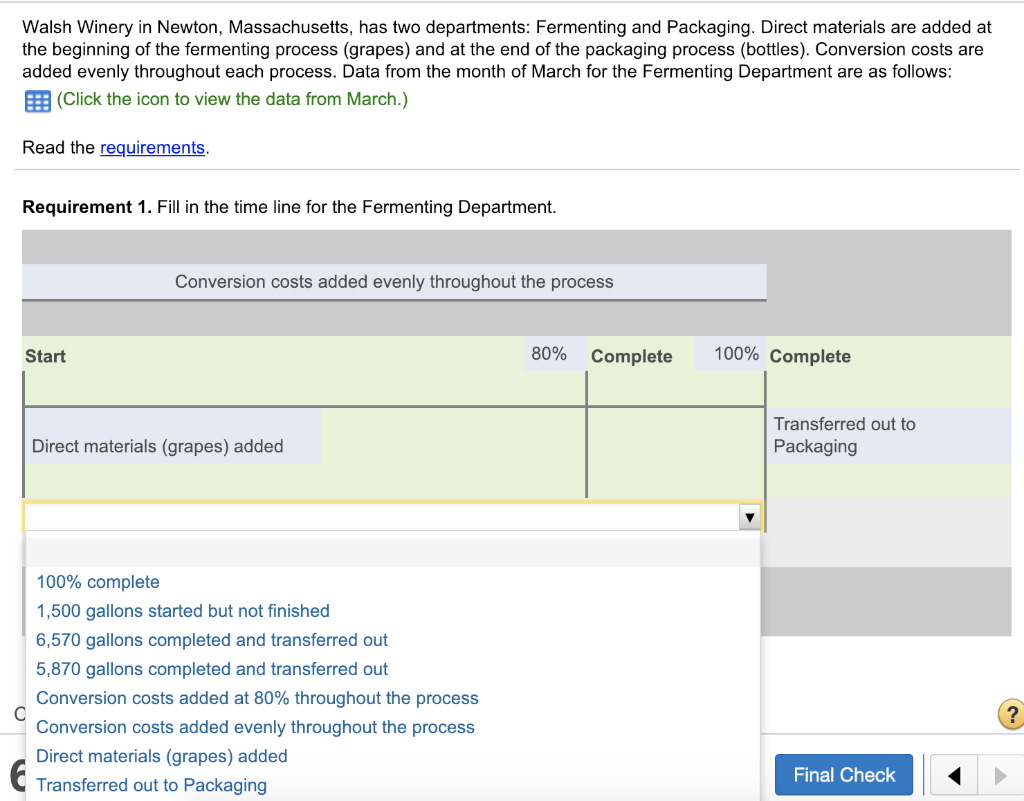

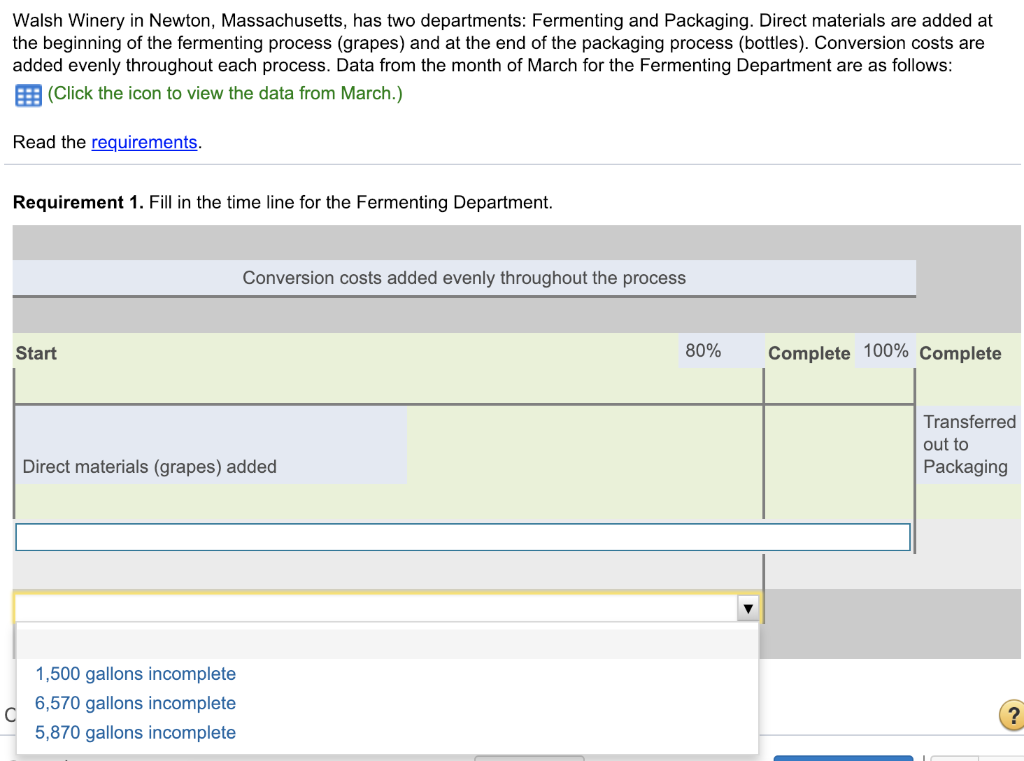

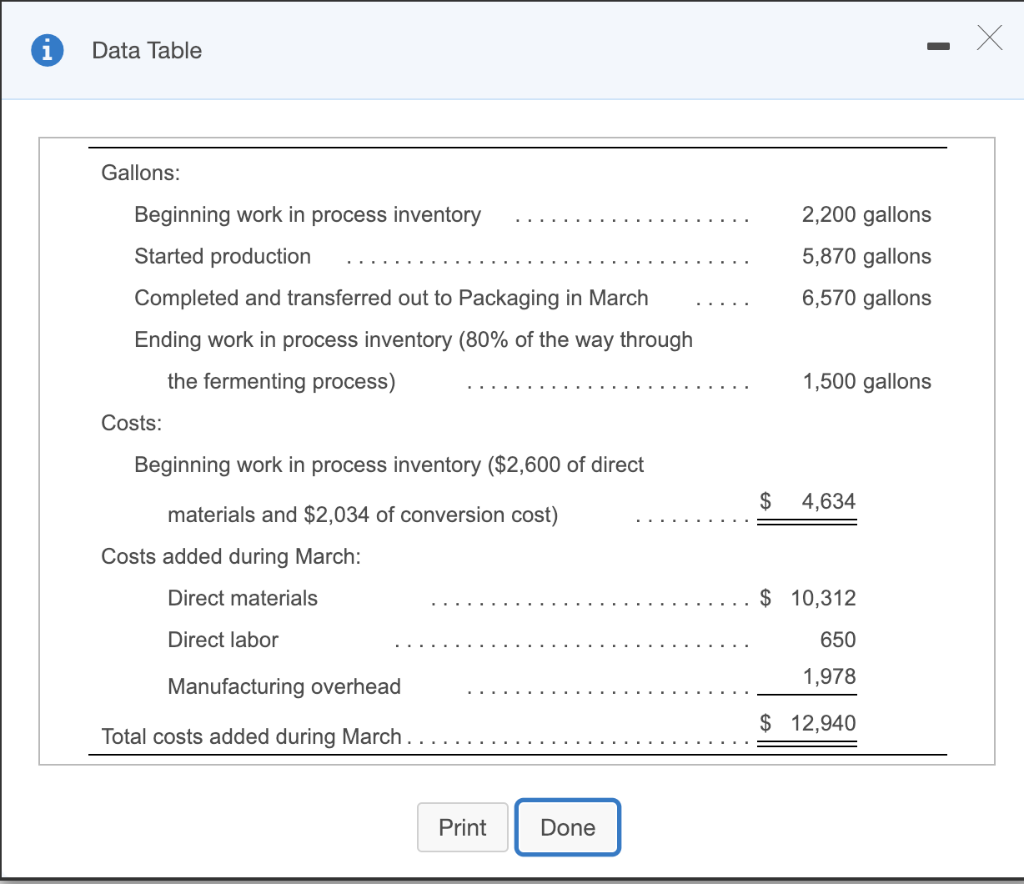

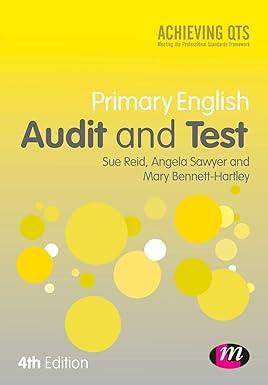

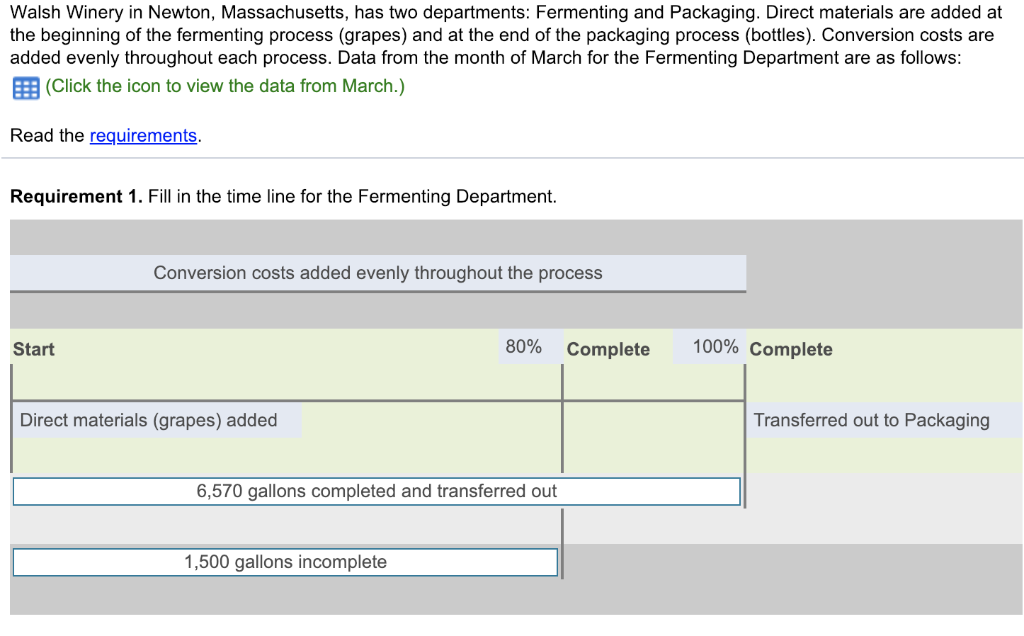

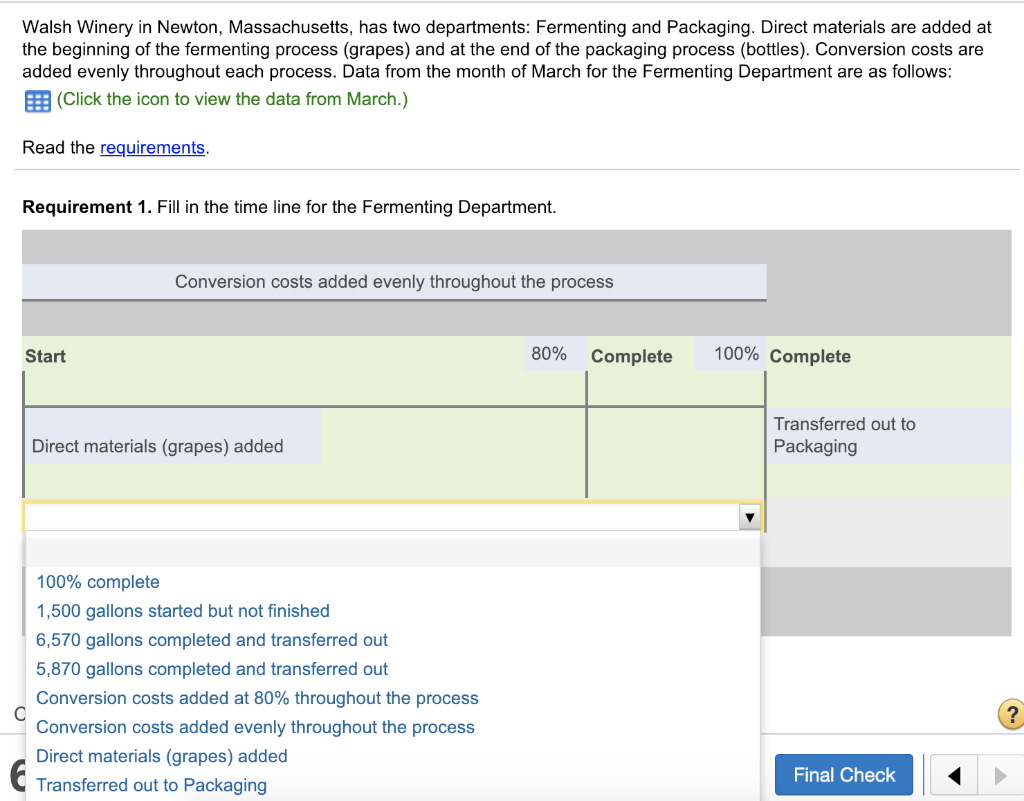

Walsh Winery in Newton, Massachusetts, has two departments: Fermenting and Packaging. Direct materials are added at the beginning of the fermenting process (grapes) and at the end of the packaging process (bottles). Conversion costs are added evenly throughout each process. Data from the month of March for the Fermenting Department are as follows: (Click the icon to view the data from March.) Read the requirements Requirement 1. Fll in the time line for the Fermenting Department. Conversion costs added evenly throughout the process Start 80% Complete 100% Complete Direct materials (grapes) added Transferred out to Packaging 6,570 gallons completed and transferred out 1,500 gallons incomplete Walsh Winery in Newton, Massachusetts, has two departments: Fermenting and Packaging. Direct materials are added at the beginning of the fermenting process (grapes) and at the end of the packaging process (bottles). Conversion costs are added evenly throughout each process. Data from the month of March for the Fermenting Department are as follows: (Click the icon to view the data from March.) Read the requirements. Requirement 1. F n the time line for the Fermenting Department. Conversion costs added evenly throughout the process Start 80% Complete 100% Complete Transferred out to Packaging Direct materials (grapes) added 100% complete 1,500 gallons started but not finished 6,570 gallons completed and transferred out 5,870 gallons completed and transferred out Conversion costs added at 80% throughout the process Conversion costs added evenly throughout the process Direct materials (grapes) added Transferred out to Packaging Final Check Walsh Winery in Newton, Massachusetts, has two departments: Fermenting and Packaging. Direct materials are added at the beginning of the fermenting process (grapes) and at the end of the packaging process (bottles). Conversion costs are added evenly throughout each process. Data from the month of March for the Fermenting Department are as follows: (Click the icon to view the data from March.) Read the requirements. Requirement 1. Fill in the time line for the Fermenting Department. Conversion costs added evenly throughout the process Start 80% Complete 100% Complete Transferred out to Packaging Direct materials (grapes) added ,500 gallons incomplete 6,570 gallons incomplete 5,870 gallons incomplete Data Table Gallons: Beginning work in process inventory 2,200 gallons 5,870 gallons 6,570 gallons Completed and transferred out to Packaging in March Ending work in process inventory (80% of the way through the fermenting process) 1,500 gallons Costs: Beginning work in process inventory ($2,600 of direct $ 4,634 materials and $2,034 of conversion cost) Costs added during March: Direct materials Direct labor Manufacturing overhead $ 10,312 650 1,978 $ 12,940 Total costs added during March. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Print Done