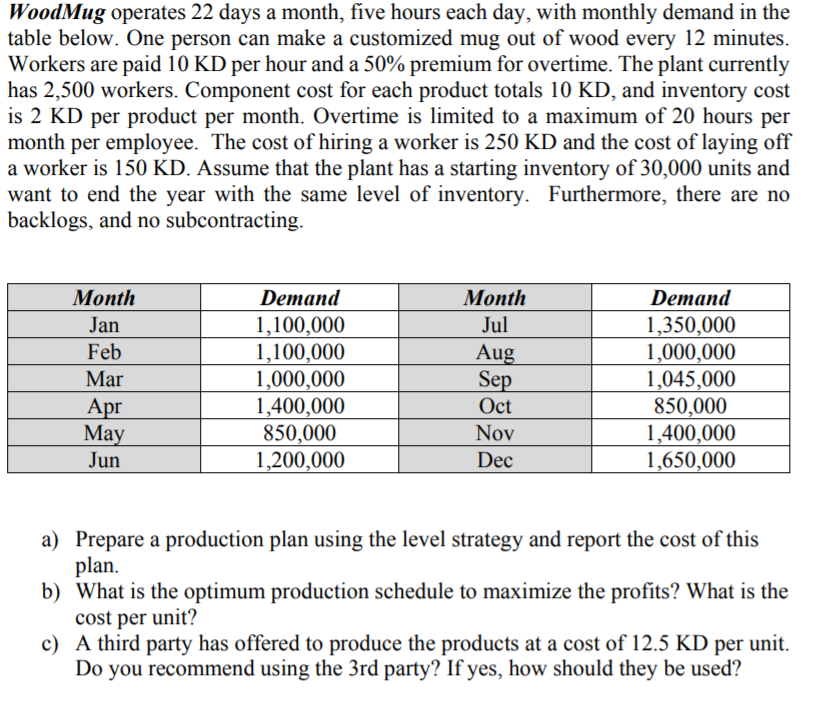

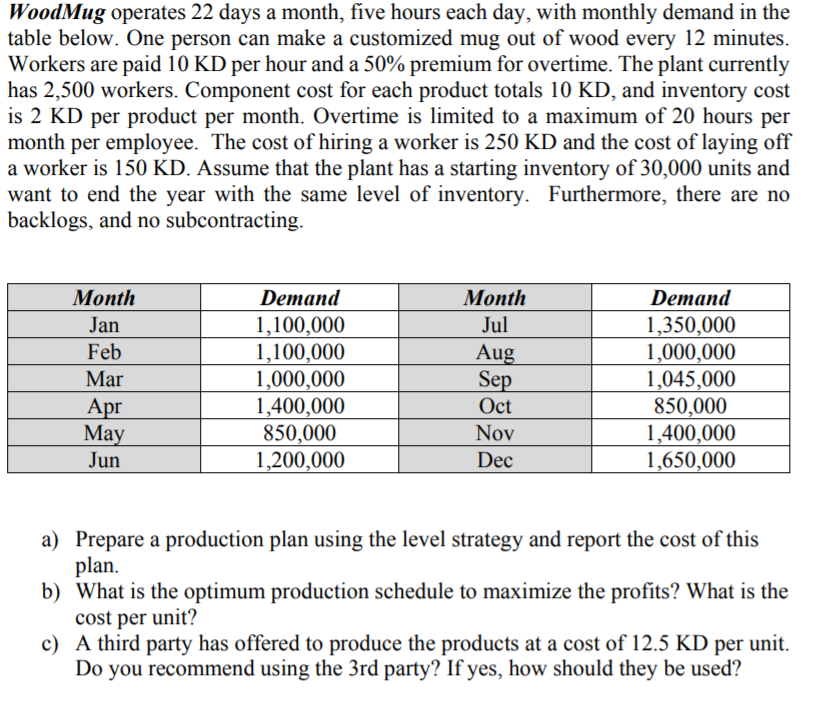

WoodMug operates 22 days a month, five hours each day, with monthly demand in the table below. One person can make a customized mug out of wood every 12 minutes. Workers are paid 10 KD per hour and a 50% premium for overtime. The plant currently has 2,500 workers. Component cost for each product totals 10 KD, and inventory cost is 2 KD per product per month. Overtime is limited to a maximum of 20 hours per month per employee. The cost of hiring a worker is 250 KD and the cost of laying off a worker is 150 KD. Assume that the plant has a starting inventory of 30,000 units and want to end the year with the same level of inventory. Furthermore, there are no backlogs, and no subcontracting. Month Jan Feb Mar Apr May Jun Demand 1,100,000 1,100,000 1,000,000 1,400,000 850,000 1,200,000 Month Jul Aug Sep Oct Nov Dec Demand 1,350,000 1,000,000 1,045,000 850,000 1,400,000 1,650,000 a) Prepare a production plan using the level strategy and report the cost of this plan. b) What is the optimum production schedule to maximize the profits? What is the cost per unit? c) A third party has offered to produce the products at a cost of 12.5 KD per unit. Do you recommend using the 3rd party? If yes, how should they be used? WoodMug operates 22 days a month, five hours each day, with monthly demand in the table below. One person can make a customized mug out of wood every 12 minutes. Workers are paid 10 KD per hour and a 50% premium for overtime. The plant currently has 2,500 workers. Component cost for each product totals 10 KD, and inventory cost is 2 KD per product per month. Overtime is limited to a maximum of 20 hours per month per employee. The cost of hiring a worker is 250 KD and the cost of laying off a worker is 150 KD. Assume that the plant has a starting inventory of 30,000 units and want to end the year with the same level of inventory. Furthermore, there are no backlogs, and no subcontracting. Month Jan Feb Mar Apr May Jun Demand 1,100,000 1,100,000 1,000,000 1,400,000 850,000 1,200,000 Month Jul Aug Sep Oct Nov Dec Demand 1,350,000 1,000,000 1,045,000 850,000 1,400,000 1,650,000 a) Prepare a production plan using the level strategy and report the cost of this plan. b) What is the optimum production schedule to maximize the profits? What is the cost per unit? c) A third party has offered to produce the products at a cost of 12.5 KD per unit. Do you recommend using the 3rd party? If yes, how should they be used