Answered step by step

Verified Expert Solution

Question

1 Approved Answer

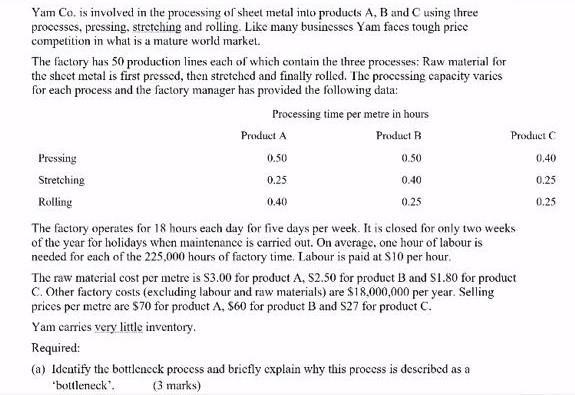

Yam Co. is involved in the processing of sheet metal into products A, B and C using three processes, pressing, stretching and rolling. Like

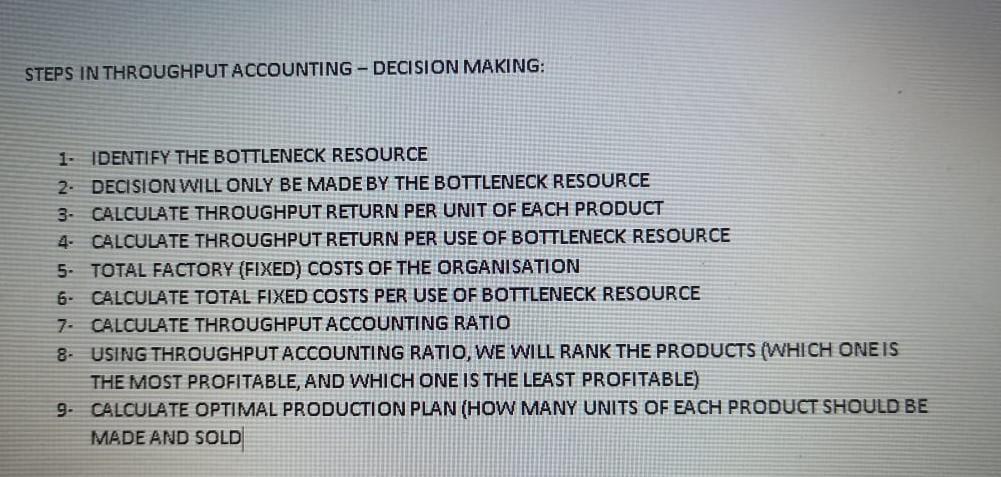

Yam Co. is involved in the processing of sheet metal into products A, B and C using three processes, pressing, stretching and rolling. Like many businesses Yam faces tough price competition in what is a mature world market. The factory has 50 production lines each of which contain the three processes: Raw material for the sheet metal is first pressed, then stretched and finally rolled. The processing capacity varies for each process and the factory manager has provided the following data: Pressing Stretching Rolling Processing time per metre in hours Product B 0.50 0.40 0.25 Product A 0.50 0.25 0.40 Product C 0.40 0.25 0.25 The factory operates for 18 hours each day for five days per week. It is closed for only two weeks of the year for holidays when maintenance is carried out. On average, one hour of labour is needed for each of the 225,000 hours of factory time. Labour is paid at $10 per hour. The raw material cost per metre is $3.00 for product A, $2.50 for product B and S1.80 for product C. Other factory costs (excluding labour and raw materials) are $18,000,000 per year. Selling prices per metre are $70 for product A. $60 for product B and S27 for product C. Yam carries very little inventory. Required: (a) Identify the bottleneck process and briefly explain why this process is described as a "bottleneck". (3 marks) STEPS IN THROUGHPUT ACCOUNTING DECISION MAKING: 1- IDENTIFY THE BOTTLENECK RESOURCE 2. DECISION WILL ONLY BE MADE BY THE BOTTLENECK RESOURCE 3- CALCULATE THROUGHPUT RETURN PER UNIT OF EACH PRODUCT 4- CALCULATE THROUGHPUT RETURN PER USE OF BOTTLENECK RESOURCE 5- TOTAL FACTORY (FIXED) COSTS OF THE ORGANISATION 6- CALCULATE TOTAL FIXED COSTS PER USE OF BOTTLENECK RESOURCE 7- CALCULATE THROUGHPUT ACCOUNTING RATIO 8 USING THROUGHPUT ACCOUNTING RATIO, WE WILL RANK THE PRODUCTS (WHICH ONE IS THE MOST PROFITABLE, AND WHICH ONE IS THE LEAST PROFITABLE) 9- CALCULATE OPTIMAL PRODUCTION PLAN (HOW MANY UNITS OF EACH PRODUCT SHOULD BE MADE AND SOLD

Step by Step Solution

There are 3 Steps involved in it

Step: 1

1 The output capacity for each process is as follows The total processing hours of the factory is given but can be proven as follows 18 hours x 5 days x 50 weeks Since 2 weeks factory is closed x 50 p...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started