Answered step by step

Verified Expert Solution

Question

1 Approved Answer

You are required to determine gear parameters of one set of gears. The number of teeth on the pinion and gear is specified for

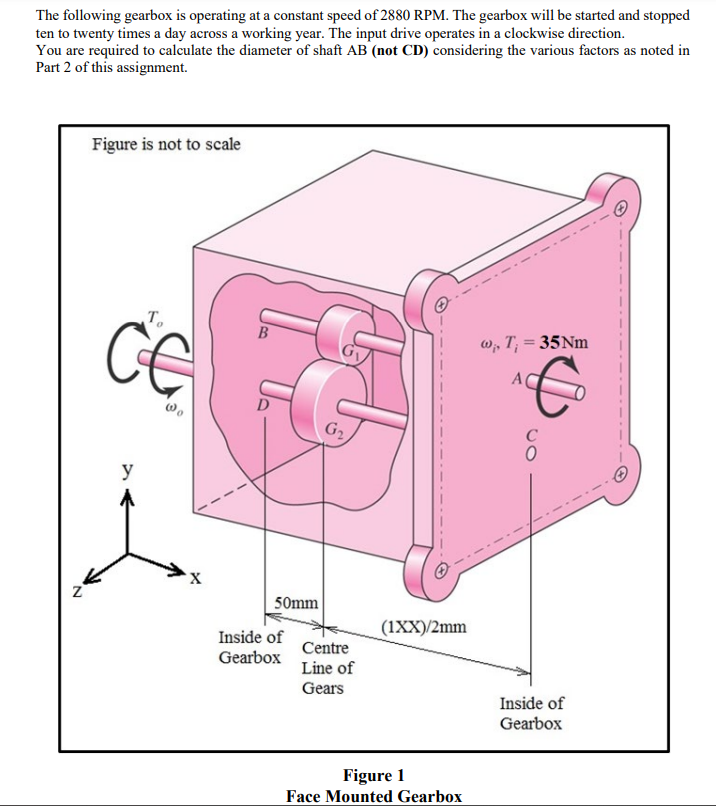

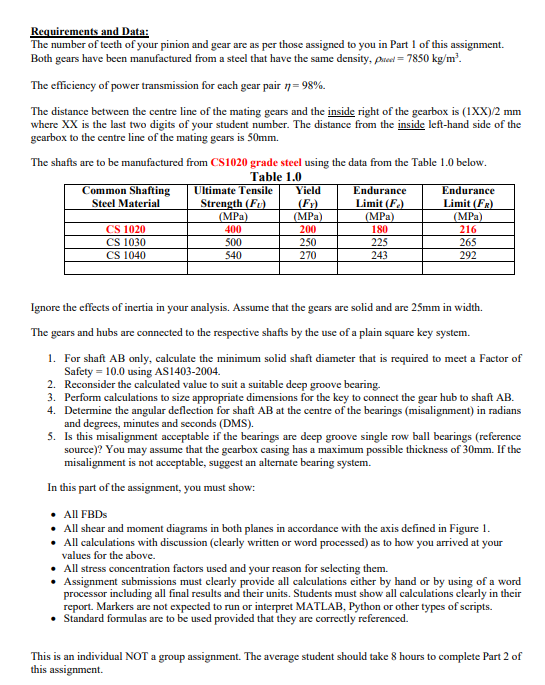

You are required to determine gear parameters of one set of gears. The number of teeth on the pinion and gear is specified for each student on the following pages. Standard Gear Requirements: Module m 15.0000 mm 20.0000 degree pressure angle addendum 1.0 module (i.e. 15.0000 mm) dedendum 1.25 module (i.e. 18.7500 mm) For a standard gear set you should calculate the following information for the pinion AND spur gear in mesh. Assume that the pinion is rotating in a clockwise direction. Calculate to four decimal places, (including units) using the correct formulas (cited from the course notes or alternate sources using APA 6th 7th or Harvard referencing.) providing clear sketches. 1. Addendum diameter 2. Pitch diameter 3. Base diameter 4. Dedendum diameter 5. Tooth width (arc length) 6. Tooth width with a 0.01 mm backlash (in mesh) 7. Contact ratio 8. Length of line of access 9. Length of line of recess 10. Length of line of single tooth contact Assignment submissions must clearly provide all calculations either by hand or by using of a word processor including all final results and their units. Students must show all calculations clearly in their report. Markers are not expected to run or interpret MATLAB. Python or other types of scripts. This is an individual NOT a group assignment. The average student should take 6 hours to complete Part 1 of this assignment. The following gearbox is operating at a constant speed of 2880 RPM. The gearbox will be started and stopped ten to twenty times a day across a working year. The input drive operates in a clockwise direction. You are required to calculate the diameter of shaft AB (not CD) considering the various factors as noted in Part 2 of this assignment. N Figure is not to scale y To X B D 50mm Inside of Gearbox G Centre Line of Gears (1XX)/2mm Figure 1 Face Mounted Gearbox @,, T; = 35Nm C A Inside of Gearbox Requirements and Data: The number of teeth of your pinion and gear are as per those assigned to you in Part 1 of this assignment. Both gears have been manufactured from a steel that have the same density, piel=7850 kg/m. The efficiency of power transmission for each gear pair 17= 98%. The distance between the centre line of the mating gears and the inside right of the gearbox is (1XX)/2 mm where XX is the last two digits of your student number. The distance from the inside left-hand side of the gearbox to the centre line of the mating gears is 50mm. The shafts are to be manufactured from CS1020 grade steel using the data from the Table 1.0 below. Table 1.0 Common Shafting Steel Material CS 1020 CS 1030 CS 1040 Ultimate Tensile Strength (Fu) (MPa) 400 500 540 Yield (Fr) (MPa) 200 250 270 Endurance Limit (F) (MPa) 180 225 243 Endurance Limit (FR) (MPa) 216 265 292 Ignore the effects of inertia in your analysis. Assume that the gears are solid and are 25mm in width. The gears and hubs are connected to the respective shafts by the use of a plain square key system. 1. For shaft AB only, calculate the minimum solid shaft diameter that is required to meet a Factor of Safety = 10.0 using AS1403-2004. 2. Reconsider the calculated value to suit a suitable deep groove bearing. 3. Perform calculations to size appropriate dimensions for the key to connect the gear hub to shaft AB. 4. Determine the angular deflection for shaft AB at the centre of the bearings (misalignment) in radians and degrees, minutes and seconds (DMS). 5. Is this misalignment acceptable if the bearings are deep groove single row ball bearings (reference source)? You may assume that the gearbox casing has a maximum possible thickness of 30mm. If the misalignment is not acceptable, suggest an alternate bearing system. In this part of the assignment, you must show: All FBDs All shear and moment diagrams in both planes in accordance with the axis defined in Figure 1. All calculations with discussion (clearly written or word processed) as to how you arrived at your values for the above. All stress concentration factors used and your reason for selecting them. Assignment submissions must clearly provide all calculations either by hand or by using of a word processor including all final results and their units. Students must show all calculations clearly in their report. Markers are not expected to run or interpret MATLAB, Python or other types of scripts. Standard formulas are to be used provided that they are correctly referenced. This is an individual NOT a group assignment. The average student should take 8 hours to complete Part 2 of this assignment.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started