Answered step by step

Verified Expert Solution

Question

1 Approved Answer

You are the auditor for the management of XY company, a manufacturing company that produces silk thread. There is a problem, namely the frequent occurrence

You are the auditor for the management of XY company, a manufacturing company that produces silk thread. There is a problem, namely the frequent occurrence of out of stock which is suspected to be due to production delays. You have conducted an operational audit in this regard. The following are your findings related to conditions, criteria, causes and effects :

Question:

Based on the conditions, criteria, causes, consequences mentioned above, provide audit conclusions and recommendations for the management of XY!

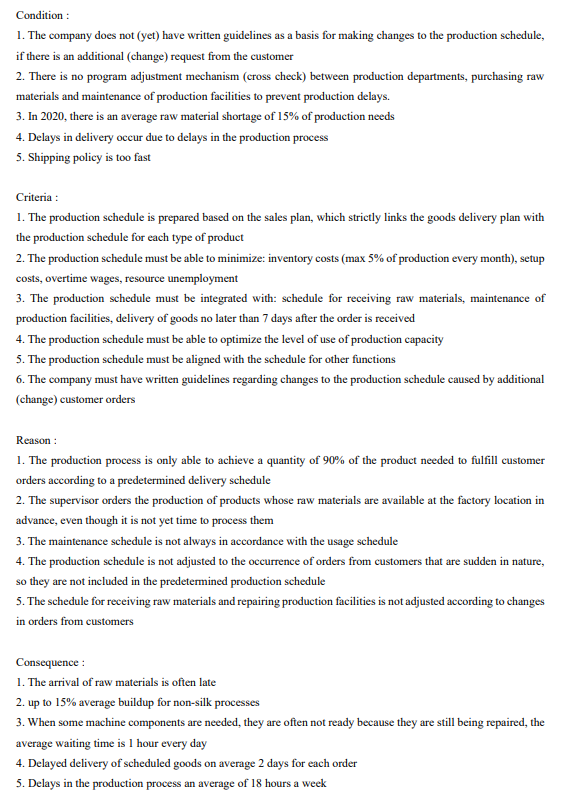

Condition : 1. The company does not (yet) have written guidelines as a basis for making changes to the production schedule, if there is an additional (change) request from the customer 2. There is no program adjustment mechanism (cross check) between production departments, purchasing raw materials and maintenance of production facilities to prevent production delays. 3. In 2020 , there is an average raw material shortage of 15% of production needs 4. Delays in delivery occur due to delays in the production process 5. Shipping policy is too fast Criteria : 1. The production schedule is prepared based on the sales plan, which strictly links the goods delivery plan with the production schedule for each type of product 2. The production schedule must be able to minimize: inventory costs (max 5% of production every month), setup costs, overtime wages, resource unemployment 3. The production schedule must be integrated with: schedule for receiving raw materials, maintenance of production facilities, delivery of goods no later than 7 days after the order is received 4. The production schedule must be able to optimize the level of use of production capacity 5. The production schedule must be aligned with the schedule for other functions 6. The company must have written guidelines regarding changes to the production schedule caused by additional (change) customer orders Reason: 1. The production process is only able to achieve a quantity of 90% of the product needed to fulfill customer orders according to a predetermined delivery schedule 2. The supervisor orders the production of products whose raw materials are available at the factory location in advance, even though it is not yet time to process them 3. The maintenance schedule is not always in accordance with the usage schedule 4. The production schedule is not adjusted to the occurrence of orders from customers that are sudden in nature, so they are not included in the predetermined production schedule 5. The schedule for receiving raw materials and repairing production facilities is not adjusted according to changes in orders from customers Consequence : 1. The arrival of raw materials is often late 2. up to 15% average buildup for non-silk processes 3. When some machine components are needed, they are often not ready because they are still being repaired, the average waiting time is 1 hour every day 4. Delayed delivery of scheduled goods on average 2 days for each order 5. Delays in the production process an average of 18 hours a weekStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started