Answered step by step

Verified Expert Solution

Question

1 Approved Answer

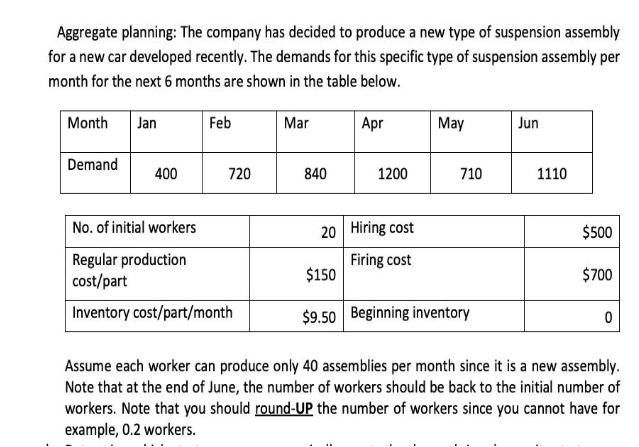

Aggregate planning: The company has decided to produce a new type of suspension assembly for a new car developed recently. The demands for this

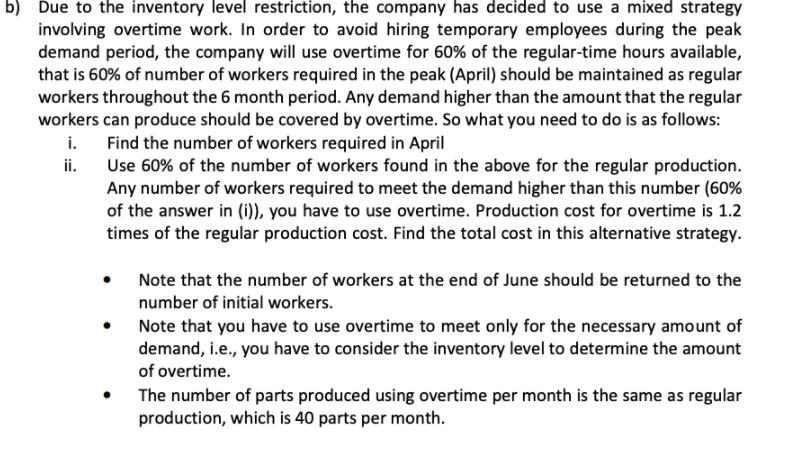

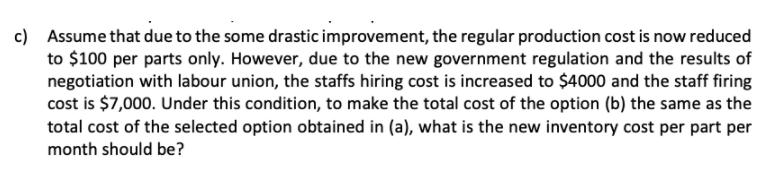

Aggregate planning: The company has decided to produce a new type of suspension assembly for a new car developed recently. The demands for this specific type of suspension assembly per month for the next 6 months are shown in the table below. Apr Month Jan Demand 400 Feb 720 No. of initial workers Regular production cost/part Inventory cost/part/month Mar 840 1200 20 Hiring cost Firing cost May 710 $150 $9.50 Beginning inventory Jun 1110 $500 $700 0 Assume each worker can produce only 40 assemblies per month since it is a new assembly. Note that at the end of June, the number of workers should be back to the initial number of workers. Note that you should round-UP the number of workers since you cannot have for example, 0.2 workers. b) Due to the inventory level restriction, the company has decided to use a mixed strategy involving overtime work. In order to avoid hiring temporary employees during the peak demand period, the company will use overtime for 60% of the regular-time hours available, that is 60% of number of workers required in the peak (April) should be maintained as regular workers throughout the 6 month period. Any demand higher than the amount that the regular workers can produce should be covered by overtime. So what you need to do is as follows: i. Find the number of workers required in April Use 60% of the number of workers found in the above for the regular production. Any number of workers required to meet the demand higher than this number (60% of the answer in (i)), you have to use overtime. Production cost for overtime is 1.2 times of the regular production cost. Find the total cost in this alternative strategy. Note that the number of workers at the end of June should be returned to the number of initial workers. Note that you have to use overtime to meet only for the necessary amount of demand, i.e., you have to consider the inventory level to determine the amount of overtime. The number of parts produced using overtime per month is the same as regular production, which is 40 parts per month. c) Assume that due to the some drastic improvement, the regular production cost is now reduced to $100 per parts only. However, due to the new government regulation and the results of negotiation with labour union, the staffs hiring cost is increased to $4000 and the staff firing cost is $7,000. Under this condition, to make the total cost of the option (b) the same as the total cost of the selected option obtained in (a), what is the new inventory cost per part per month should be?

Step by Step Solution

★★★★★

3.40 Rating (166 Votes )

There are 3 Steps involved in it

Step: 1

Number of workers required in April The total demand for April is 840 pa...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started