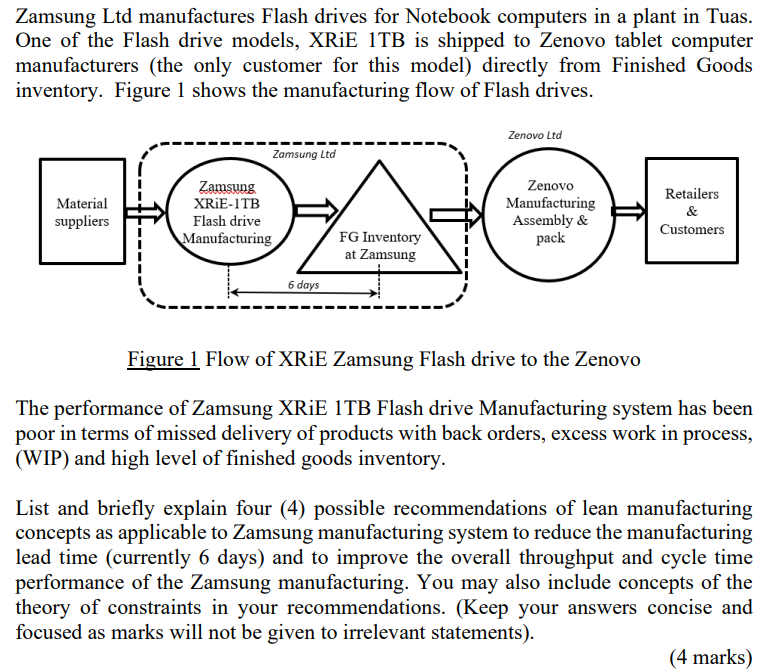

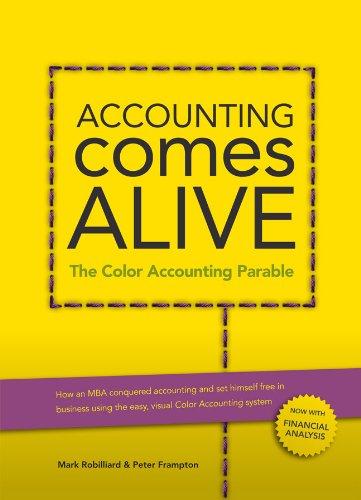

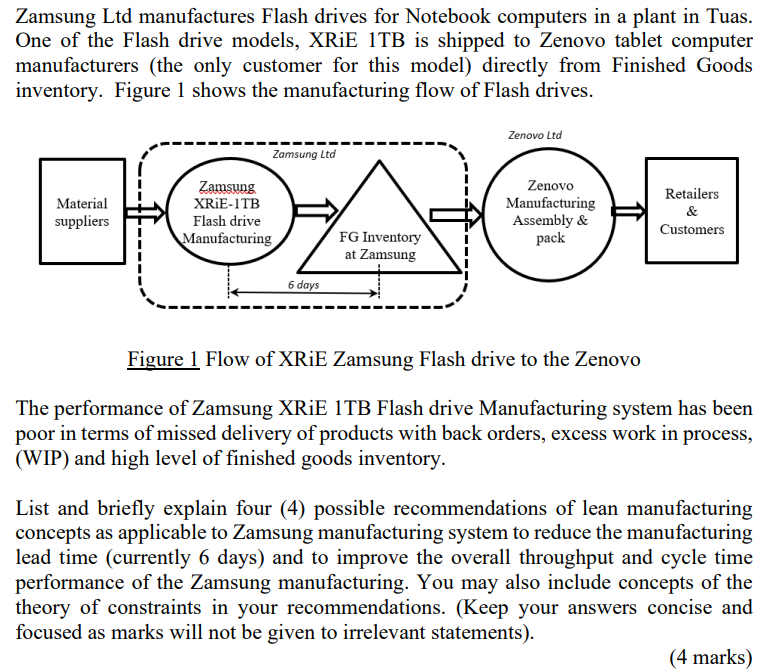

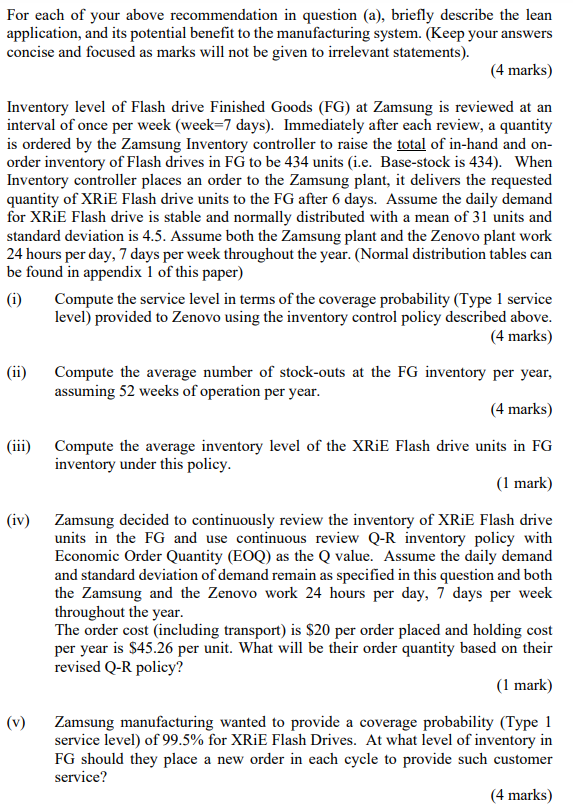

Zamsung Ltd manufactures Flash drives for Notebook computers in a plant in Tuas. One of the Flash drive models, XRIE 1TB is shipped to Zenovo tablet computer manufacturers (the only customer for this model) directly from Finished Goods inventory. Figure 1 shows the manufacturing flow of Flash drives. Zenovo Ltd Zamsung Ltd Material suppliers Zamsung XRIE-1TB Flash drive Manufacturing Zenovo Manufacturing Assembly & pack Retailers & Customers FG Inventory at Zamsung 6 days Figure 1 Flow of XRiE Zamsung Flash drive to the Zenovo The performance of Zamsung XRIE 1TB Flash drive Manufacturing system has been poor in terms of missed delivery of products with back orders, excess work in process, (WIP) and high level of finished goods inventory. List and briefly explain four (4) possible recommendations of lean manufacturing concepts as applicable to Zamsung manufacturing system to reduce the manufacturing lead time (currently 6 days) and to improve the overall throughput and cycle time performance of the Zamsung manufacturing. You may also include concepts of the theory of constraints in your recommendations. (Keep your answers concise and focused as marks will not be given to irrelevant statements). (4 marks) For each of your above recommendation in question (a), briefly describe the lean application, and its potential benefit to the manufacturing system. (Keep your answers concise and focused as marks will not be given to irrelevant statements). (4 marks) Inventory level of Flash drive Finished Goods (FG) at Zamsung is reviewed at an interval of once per week (week=7 days). Immediately after each review, a quantity is ordered by the Zamsung Inventory controller to raise the total of in-hand and on- order inventory of Flash drives in FG to be 434 units i.e. Base-stock is 434). When Inventory controller places an order to the Zamsung plant, it delivers the requested quantity of XRIE Flash drive units to the FG after 6 days. Assume the daily demand for XRIE Flash drive is stable and normally distributed with a mean of 31 units and standard deviation is 4.5. Assume both the Zamsung plant and the Zenovo plant work 24 hours per day, 7 days per week throughout the year. (Normal distribution tables can be found in appendix 1 of this paper) (i) Compute the service level in terms of the coverage probability (Type 1 service level) provided to Zenovo using the inventory control policy described above. (4 marks) (ii) Compute the average number of stock-outs at the FG inventory per year, assuming 52 weeks of operation per year. (4 marks) (iii) Compute the average inventory level of the XRIE Flash drive units in FG inventory under this policy. (1 mark) (iv) Zamsung decided to continuously review the inventory of XRIE Flash drive units in the FG and use continuous review Q-R inventory policy with Economic Order Quantity (EOQ) as the Q value. Assume the daily demand and standard deviation of demand remain as specified in this question and both the Zamsung and the Zenovo work 24 hours per day, 7 days per week throughout the year. The order cost (including transport) is $20 per order placed and holding cost per year is $45.26 per unit. What will be their order quantity based on their revised Q-R policy? (1 mark) (v) Zamsung manufacturing wanted to provide a coverage probability (Type 1 service level) of 99.5% for XRIE Flash Drives. At what level of inventory in FG should they place a new order in each cycle to provide such customer service? (4 marks) Zamsung Ltd manufactures Flash drives for Notebook computers in a plant in Tuas. One of the Flash drive models, XRIE 1TB is shipped to Zenovo tablet computer manufacturers (the only customer for this model) directly from Finished Goods inventory. Figure 1 shows the manufacturing flow of Flash drives. Zenovo Ltd Zamsung Ltd Material suppliers Zamsung XRIE-1TB Flash drive Manufacturing Zenovo Manufacturing Assembly & pack Retailers & Customers FG Inventory at Zamsung 6 days Figure 1 Flow of XRiE Zamsung Flash drive to the Zenovo The performance of Zamsung XRIE 1TB Flash drive Manufacturing system has been poor in terms of missed delivery of products with back orders, excess work in process, (WIP) and high level of finished goods inventory. List and briefly explain four (4) possible recommendations of lean manufacturing concepts as applicable to Zamsung manufacturing system to reduce the manufacturing lead time (currently 6 days) and to improve the overall throughput and cycle time performance of the Zamsung manufacturing. You may also include concepts of the theory of constraints in your recommendations. (Keep your answers concise and focused as marks will not be given to irrelevant statements). (4 marks) For each of your above recommendation in question (a), briefly describe the lean application, and its potential benefit to the manufacturing system. (Keep your answers concise and focused as marks will not be given to irrelevant statements). (4 marks) Inventory level of Flash drive Finished Goods (FG) at Zamsung is reviewed at an interval of once per week (week=7 days). Immediately after each review, a quantity is ordered by the Zamsung Inventory controller to raise the total of in-hand and on- order inventory of Flash drives in FG to be 434 units i.e. Base-stock is 434). When Inventory controller places an order to the Zamsung plant, it delivers the requested quantity of XRIE Flash drive units to the FG after 6 days. Assume the daily demand for XRIE Flash drive is stable and normally distributed with a mean of 31 units and standard deviation is 4.5. Assume both the Zamsung plant and the Zenovo plant work 24 hours per day, 7 days per week throughout the year. (Normal distribution tables can be found in appendix 1 of this paper) (i) Compute the service level in terms of the coverage probability (Type 1 service level) provided to Zenovo using the inventory control policy described above. (4 marks) (ii) Compute the average number of stock-outs at the FG inventory per year, assuming 52 weeks of operation per year. (4 marks) (iii) Compute the average inventory level of the XRIE Flash drive units in FG inventory under this policy. (1 mark) (iv) Zamsung decided to continuously review the inventory of XRIE Flash drive units in the FG and use continuous review Q-R inventory policy with Economic Order Quantity (EOQ) as the Q value. Assume the daily demand and standard deviation of demand remain as specified in this question and both the Zamsung and the Zenovo work 24 hours per day, 7 days per week throughout the year. The order cost (including transport) is $20 per order placed and holding cost per year is $45.26 per unit. What will be their order quantity based on their revised Q-R policy? (1 mark) (v) Zamsung manufacturing wanted to provide a coverage probability (Type 1 service level) of 99.5% for XRIE Flash Drives. At what level of inventory in FG should they place a new order in each cycle to provide such customer service? (4 marks)