Question: A depropanizer distillation column is designed to operate at a feed stage pressure of 315 psia for separating a feed into distillate and bottoms with

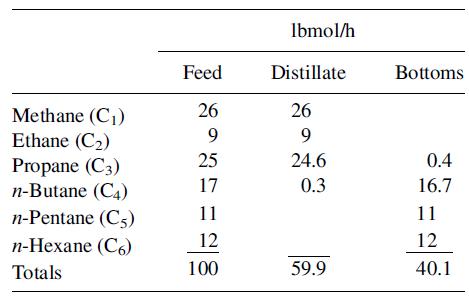

A depropanizer distillation column is designed to operate at a feed stage pressure of 315 psia for separating a feed into distillate and bottoms with the following flow rates:

The feed is 66 mol% vapor at tower pressure. Steam at 315 psia and cooling water at 65F are available for the reboiler and condenser. Assume a 2-psi column pressure drop.

(a) Should a total condenser be used for this column?

(b) What are the feed temperature, K-values, and relative volatilities (with reference to C3) at the feed temperature and pressure?

(c) If the reflux ratio is 1.3 times the minimum reflux, what is the actual reflux ratio? How many theoretical plates are needed in the rectifying and stripping sections?

(d) Compute the separation of species. How will the separation differ if a reflux ratio of 1.5, 15 theoretical plates, and feed at the ninth plate are chosen?

(e) For part (c), compute the temperature and concentrations on each stage. What is the effect of feed plate location? How will the results differ if a reflux ratio of 1.5 and 15 theoretical plates are used?

Methane (C) Ethane (C) Propane (C3) n-Butane (C4) n-Pentane (C5) n-Hexane (C6) Totals Feed 26 9 25 17 12 100 lbmol/h Distillate 26 9 24.6 0.3 59.9 Bottoms 0.4 16.7 |5= 40.1

Step by Step Solution

3.36 Rating (159 Votes )

There are 3 Steps involved in it

a A total condenser should be used for this column because the distillate contains all of the light ... View full answer

Get step-by-step solutions from verified subject matter experts