Question: A distillation unit consists of a partial reboiler, a bubble-cap column, and a total condenser. The overall plate efficiency is 65%. The feed is a

A distillation unit consists of a partial reboiler, a bubble-cap column, and a total condenser. The overall plate efficiency is 65%. The feed is a bubble-point liquid of 50 mol% benzene in toluene, which is fed to the optimal plate. The column is to produce a distillate containing 95 mol% benzene and a bottoms of 95 mol% toluene. Calculate for an operating pressure of 1 atm the:

(a) Minimum reflux ratio (L / D)min;

(b) Minimum number of actual plates;

(c) Number of actual plates needed for a reflux ratio (L/D) of 50% more than the minimum;

(d) Kg/h of distillate and bottoms, if the feed is 907.3 kg/h; and

(e) Saturated steam at 273.7 kPa required in kg/h for the reboiler using the enthalpy data below and any assumptions necessary.

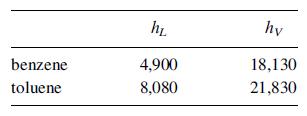

(f) Make a rigorous enthalpy balance on the reboiler, using the enthalpy data below and assuming ideal solutions. Enthalpies are in Btu/lbmol at reboiler temperature:

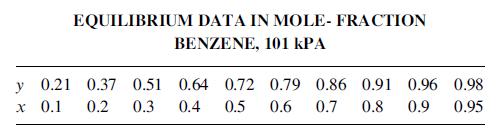

Vapor–liquid equilibrium data are given in Exercise 7.13.

Data From Exercise 7.13

A column at 101 kPa is to separate 30 kg/h of a bubble-point solution of benzene and toluene containing 0.6 mass-fraction toluene into an overhead product of 0.97 mass-fraction benzene and a bottoms product of 0.98 mass-fraction toluene at a reflux ratio of 3.5. The feed is sent to the optimal tray, and the reflux is at saturation temperature. Determine the:

benzene toluene hL 4,900 8,080 hy 18,130 21,830

Step by Step Solution

3.41 Rating (154 Votes )

There are 3 Steps involved in it

a Minimum reflux ratio L Dmin 109 b Minimum number of actual plates 8 c Number ... View full answer

Get step-by-step solutions from verified subject matter experts