Question: The absorber of Examples 6.1 and 6.4 is being scaled up by a factor of 15, so a column with an 11.5-ft diameter will be

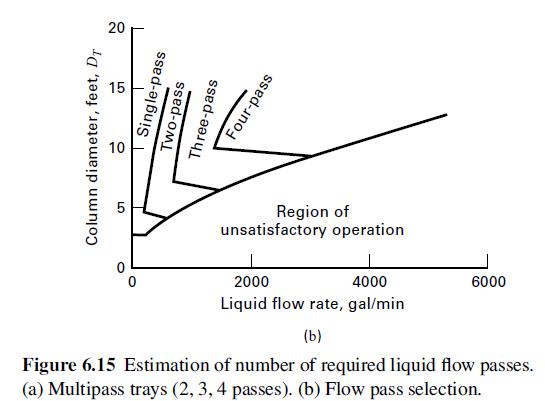

The absorber of Examples 6.1 and 6.4 is being scaled up by a factor of 15, so a column with an 11.5-ft diameter will be needed. Because of the 30% efficiency for the original tray, a new design has been developed and tested in an Oldershaw column. The resulting Murphree vapor-point efficiency, EOV, for the new tray design for this system is 55%. Estimate EMV and Eo. To estimate the length of the liquid flow path, ZL, use Figure 6.15. Assume that u/DE = 6 ft-1.

In a bioprocess, molasses is fermented to produce a liquor containing ethyl alcohol. A CO2-rich vapor with a small amount of ethyl alcohol is evolved. The alcohol is recovered by absorption with water in a sieve-tray tower. Determine the number of equilibrium stages required for countercurrent flow of liquid and gas, assuming isothermal, isobaric conditions and that only alcohol is absorbed.

Entering gas is 180 kmol/h; 98% CO2, 2% ethyl alcohol; 30οC, 110 kPa.

Entering liquid absorbent is 100% water; 30οC, 110 kPa.

Required recovery (absorption) of ethyl alcohol is 97%.

Column diameter, feet, Dr 20 10 01 Single-pass Two-pass Three-pass Four-pass Region of unsatisfactory operation 4000 2000 Liquid flow rate, gal/min 0009 (b) Figure 6.15 Estimation of number of required liquid flow passes. (a) Multipass trays (2, 3, 4 passes). (b) Flow pass selection.

Step by Step Solution

3.34 Rating (163 Votes )

There are 3 Steps involved in it

EMV 055 Eo 049 ZL 08 Number of stages 24 Explanation The number o... View full answer

Get step-by-step solutions from verified subject matter experts