6. What are the main differences in operations tasks of running the proposed retail shop? What are...

Question:

6. What are the main differences in operations tasks of running the proposed retail shop? What are the implications of this for the owners?

September 2004 was a year to remember for Jean and Dave Fulbright! Their twin sons, Michael and Alan, then 5 years old, started school, and in the same month, Dave, a 29-year-old master baker at a large bakery, was made redundant. Jean, who had a part-time secretarial job with a local builder, saw this misfortune to be an unrepeatable opportunity. They had always wanted to work together, and it seemed to be a good chance to set up a small speciality business, based on Dave’s skills and financed by his redundancy payments plus a small loan.

Traditionally, small local baking and confectionery businesses produce a wide range of breads, cakes, biscuits, etc., many on a daily basis. This involves a very early start (4 am), high complexity and considerable risk. Dave wanted a ‘simpler business that would involve relatively normal hours of work, for both himself and his wife’. Neither wanted to be employers; the business would be run by just the two of them. Dave felt that his greatest satisfaction came from producing high-quality decorated fruit cakes, so together they decided that there was an opportunity to specialize in this product. Using an old family recipe, samples were made and packaged. ‘Market research’ was confined to taking these samples to various retail outlets in the area; the reaction was so overwhelming, and the potential margin seemed so high, that by January 2003 they were in business. They rented a small modern factory near home, modestly equipped with weighing and preparation equipment, a large 15 kg food mixer, two small catering ovens, a small cool room and sundry utensils. Later, Dave recalled: ‘In early 2005, we only made one size: beautiful 2 kg cakes, symmetrically decorated on top with a pattern of almonds, cherries, and walnuts and ginger.

Packing Cakes are turned out onto racks to cool overnight. The next day, once the first batches are in the oven, the previous day’s cakes are inspected, packed in a film, a decorative ribbon and an outerwrap, and then labelled and dated. Packed cakes are then carried to the cool room and stacked according to size. These processes take two people six minutes per cake (either size). The couple take one hour for lunch from 12.30 to 1.30 pm (when Oven 2 is ready to unload).

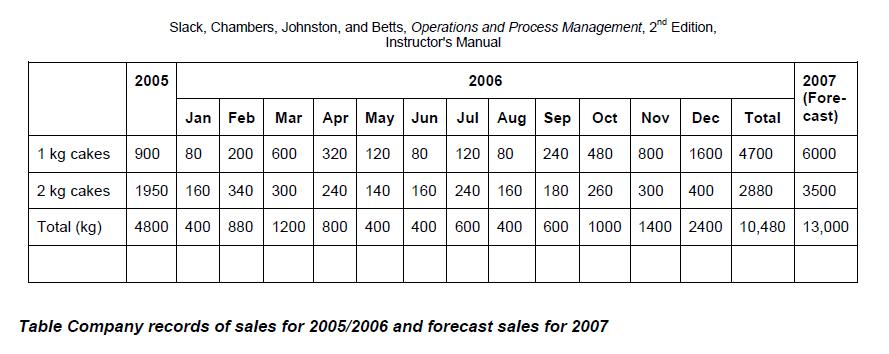

Planning ‘The only periods in 2006 that we changed production were in March, April, November and December, when we increased the 2 kg output only by 50 per cent (one extra batch per day). I had to bake the 2 kg cakes in Oven 1 and the quality wasn’t really so good, but none of our regular customers noticed! Even so, I had to work into the evenings all those months; it was a lot of work. All other months we have kept to the plan of two batches of each size each day (1 kg, followed by 2 kg, 1 kg, 2 kg), which helps us keep to a rhythm’.

Sales Records were kept of monthly sales of each size during 2006 (see table below). On 1st January 2006, there was an opening stock of 100 of each size of cake. Dave commented:

‘I am worried that we won’t be able to cope with demand in 2007, and that we will start giving bad service. Perhaps we should drop the idea of selling to the tourist spots, although the margins are very attractive. Clearly, we must not upset the retailers who give us so much business’.

Step by Step Answer:

Operations And Process Management Principles And Practice For Strategic Impact

ISBN: 9780273718512

2nd Edition

Authors: Nigel Slack , Stuart Chambers , Robert Johnston , Alan Betts