3. After looking over the level production plan, David Griffin, vice president of manufacturing, speaks up: This

Question:

3. After looking over the level production plan, David Griffin, vice president of manufacturing, speaks up: “This looks OK, but you know what bugs me about it? The assumption that if a worker is available, that worker has to be making gauge sets, even if we don’t need any more.

It might make sense in some cases to just have the worker not produce, rather than laying a worker off in one month and hiring someone else back the next.” Do you agree? What are the holding costs associated with having an extra worker produce gauge sets for one month? How do these compare to the layoff and hiring costs? How might a strategy of keeping extra workers idle affect the estimated manufacturing costs for the gauge sets? (Hint:

Labor costs have to be accounted for somewhere.)

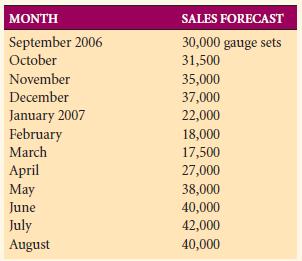

June 15, 2009.—It has been two weeks since their contentious semiannual planning meeting, and the senior staff members for Covolo Diving Gear are getting ready to start their first monthly S&OP meeting. Gina Covolo, CEO, gets the ball rolling:

I know it’s been a busy two weeks for all of you, and I appreciate you working extra time to get ready for this meeting. Production is already set for the next two months, so we’re going to start by planning for this September through the following August. I’ve had Patricia from marketing develop a sales forecast for these 12 months, and I’ve also had David from manufacturing estimate manufacturing costs and labor requirements, as well as capacity in the plant.Mary from HR was also good enough to come up with some estimates of how much it costs to hire and train new workers, as well as the cost of laying off folks. Finally, Jack from purchasing was able to get the accounting folks to estimate the cost of holding a gauge set in inventory for a month. So let’s see what we’ve got.

Mary passes out the following information to all of the attendees:

■ Manufacturing cost per gauge set: $74.50 ■ Holding cost: $8 per gauge set per month ■ Average labor hours required per gauge set:

0.25 hours ■ Labor hours available per employee per month: 160 ■ Plant capacity: 35,000 gauge sets per month ■ Cost to hire and train a new employee: $1250 ■ Cost to lay off an employee: $500 ■ Beginning and ending workforce is 50 ■ Beginning inventory is 10,000

Step by Step Answer:

Introduction To Operations And Supply Chain Management

ISBN: 9780131791039

2nd Edition

Authors: Cecil C. Bozarth, Robert B. Handfield