8.37. An article in Soldering & Surface Mount Technology (Characterization of a Solder Paste Printing Process and

Question:

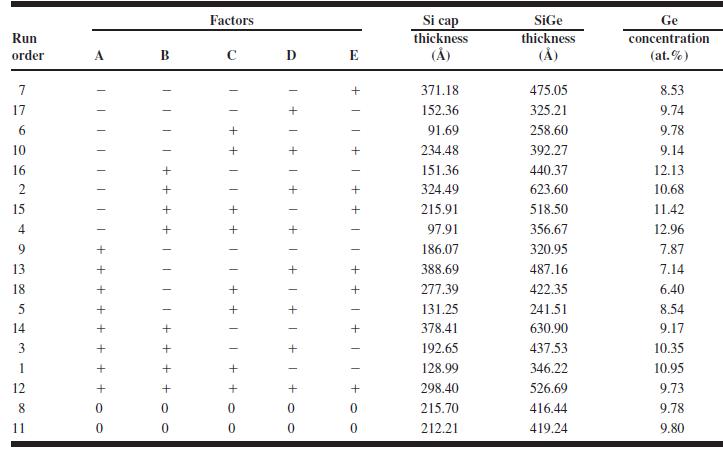

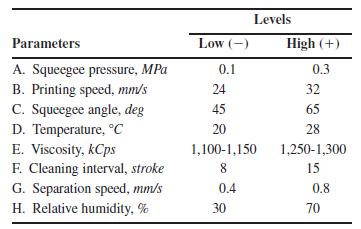

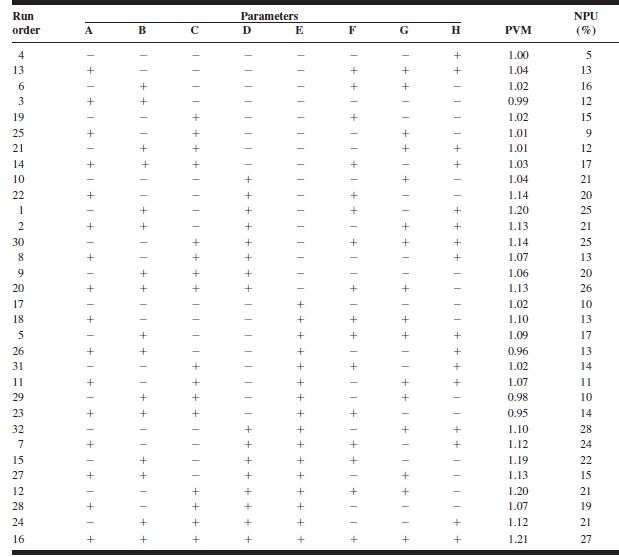

8.37. An article in Soldering & Surface Mount Technology (“Characterization of a Solder Paste Printing Process and Its Optimization,” 1999, Vol. 11, No. 3, pp. 23–26) describes the use of a 28!3 fractional factorial experiment to study the effect of eight factors on two responses; percentage volume matching (PVM) – the ratio of the actual printed solder paste volume to the designed volume; and non-conformities per unit (NPU) – the number of solder paste printing defects determined by visual inspection (206 magnification) after printing according to an industry workmanship standard. The factor levels are shown below and the test matrix and response data are shown in Table P8.9.

(a) Verify that the generators are I $ ABCF, I $ ABDG, and I $ BCDEH for this design.

(b) What are the aliases for the main effects and twofactor interactions? You can ignore all interactions of order three and higher.

(c) Analyze both the PVM and NPU responses.

(d) Analyze the residual for both responses. Are there any problems with model adequacy?

(e) The ideal value of PVM is unity and the NPU response should be as small as possible. Recommend suitable operating conditions for the process based on the experimental results.

Step by Step Answer: