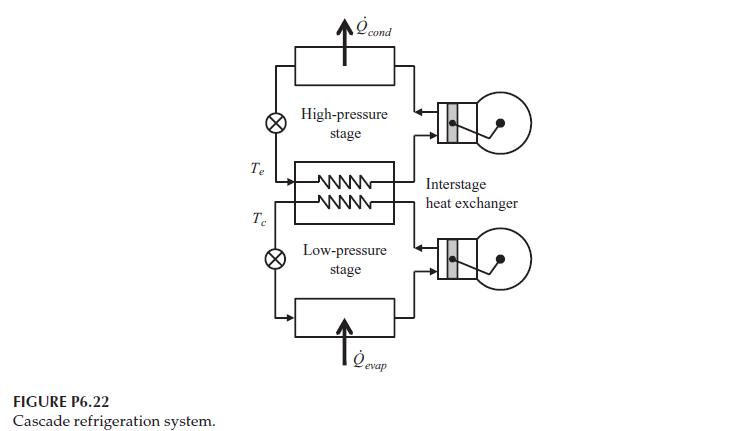

Question: A cascade refrigeration cycle is shown in Figure P6.22. The purpose of a refrigeration cycle of this type is to achieve very low temperature refrigeration

A cascade refrigeration cycle is shown in Figure P6.22. The purpose of a refrigeration cycle of this type is to achieve very low temperature refrigeration while saving energy costs. Energy costs are reduced because the work required for the two-stage cascade system is lower than the compression for a single stage operating between the same source and sink conditions. In the interstage heat exchanger, the refrigerant in the low-pressure stage leaves at Tc. The refrigerant enters the interstage heat exchanger from the high-pressure stage at Te. The overall heat transfer coefficient in the interstage heat exchanger is U = 800 W/m2-K and the total heat transferred between the two stages is 160 kW.

A cost analysis reveals that the initial cost of the interstage heat exchanger is related to the heat transfer area by,

where a1 = 100 $/m2. The cost of energy required by the compressor of each stage is a function of the refrigerant temperatures in the interstage heat exchanger. An economic analysis conducted over the expected life of the system shows that the present value of the lifetime energy costs for each stage is given by,

In these cost equations, a2 = 127,000 $, a3 = 150 $/K, a4 = 189,000 $, and a5 = −0.3 $/K2. Notice that the temperatures must be on the kelvin (K) scale.

a. Using the method of Lagrange multipliers, determine the minimum cost of this cascade refrigeration system

b. What are the values of the design variables that result in the minimum cost calculated in Part (a)?

c. Using the value(s) of the Lagrange multiplier(s), estimate the minimum cost of the system if the heat transfer rate between the fluids in the interstage heat exchanger was increased to 170 kW.

ICHX = a A

Step by Step Solution

3.42 Rating (152 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts