A flow rate of 32,000 cfm of gas at a temperature of 120F and a pressure of

Question:

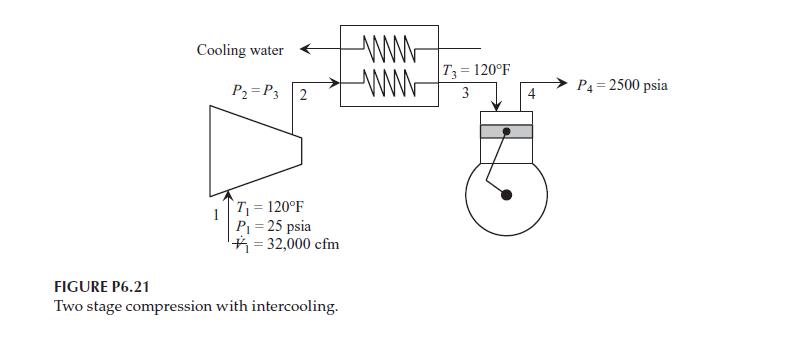

A flow rate of 32,000 cfm of gas at a temperature of 120°F and a pressure of 25 psia is to be compressed to 2500 psia. Under these conditions, the gas behaves according to the ideal gas law. The choice of compressor type is influenced by the fact that centrifugal compressors can handle high-volume flow rates but develop only low-pressure ratios per stage. A reciprocating compressor, on the other hand, is suited to low volume flow rates but can develop high pressure ratios. To combine the advantages of each, the compression will be done using a low-stage centrifugal compressor and a high-stage reciprocating compressor. Between the compressor stages, an intercooler is used to return the gas temperature to 120°F.

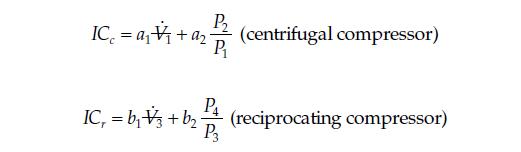

A sketch of this dual-stage compressor system is shown in Figure P6.21. The first cost of each compressor, expressed in terms of volume flow rates and pressure ratios are given by the following equations, In the above equations, a1 = 0.035

In the above equations, a1 = 0.035

$/cfm, a2 = 1700 $, b1 = 0.095 $/cfm, and b2 = 900 $.

Using the method of Lagrange multipliers, determine the

a. Minimum first cost of the compressors

b. Pressure ratios across each compressor to achieve this optimum condition

Step by Step Answer:

Thermal Energy Systems Design And Analysis

ISBN: 9781138735897

2nd Edition

Authors: Steven G. Penoncello