Question: Design a double pipe heat exchanger to cool a flow of liquid benzene from 85F to 60F. The mass flow rate of the benzene is

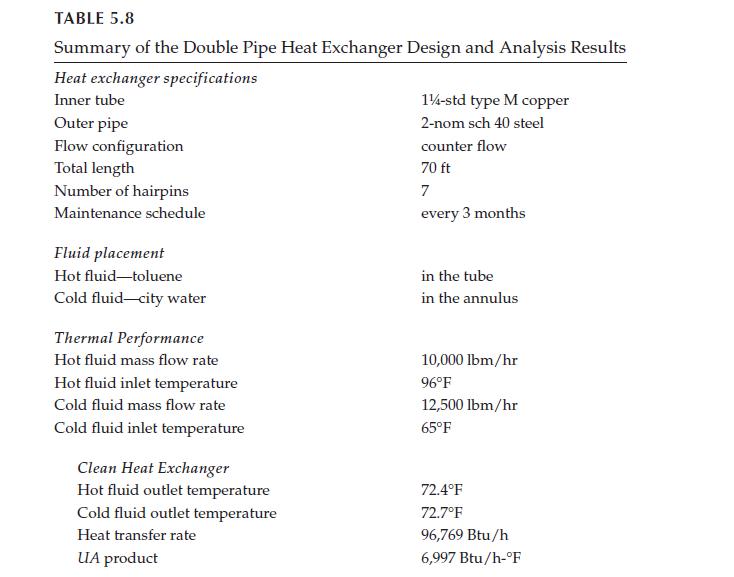

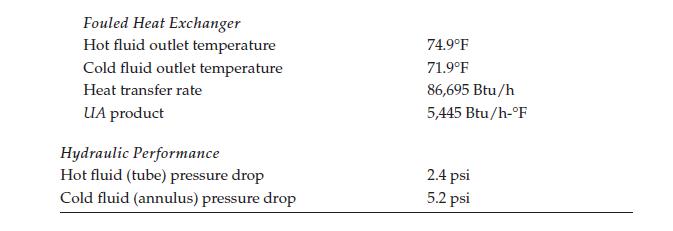

Design a double pipe heat exchanger to cool a flow of liquid benzene from 85°F to 60°F. The mass flow rate of the benzene is 12,500 lbm/h. City water at 50°F is available to provide the required cooling. The water supply flow rate is available up to 16,000 lbm/h. Once the design process is complete, analyze the heat exchanger to determine its thermal and hydraulic performance. Report your results in a table similar to Table 5.8. Justify your selections by providing all calculations required to design and analyze the heat exchanger (e.g., computer code, spreadsheets, and/or hand calculations).

TABLE 5.8 Summary of the Double Pipe Heat Exchanger Design and Analysis Results Heat exchanger specifications Inner tube Outer pipe Flow configuration Total length Number of hairpins Maintenance schedule Fluid placement Hot fluid-toluene Cold fluid-city water Thermal Performance Hot fluid mass flow rate Hot fluid inlet temperature Cold fluid mass flow rate Cold fluid inlet temperature Clean Heat Exchanger Hot fluid outlet temperature Cold fluid outlet temperature Heat transfer rate UA product 144-std type M copper 2-nom sch 40 steel counter flow 70 ft 7 every 3 months in the tube in the annulus 10,000 lbm/hr 96F 12,500 lbm/hr 65F 72.4F 72.7F 96,769 Btu/h 6,997 Btu/h-F

Step by Step Solution

3.46 Rating (156 Votes )

There are 3 Steps involved in it

The design of a double pipe heat exchanger requires a number of steps ranging from initial assumptions and selections to detailed calculations and validation Heres an overview of the process 1 Initial ... View full answer

Get step-by-step solutions from verified subject matter experts