Question: The production of paper involves a pulping step to break down wood chips into cellulose and lignin. In the Kraft process, an aqueous, pulping-feed solution,

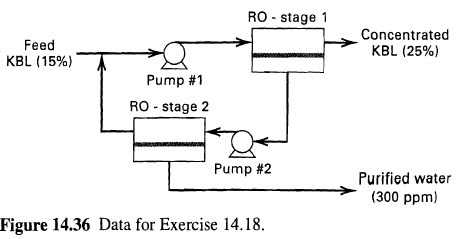

The production of paper involves a pulping step to break down wood chips into cellulose and lignin. In the Kraft process, an aqueous, pulping-feed solution, known as white liquor, is used that consists of dissolved inorganic chemicals such as sodium sulfide and sodium hydroxide. Following removal of the pulp (primarily cellulose), a solution known as weak (Kraft) black liquor (KBL) is left, which is regenerated to recover white liquor for recycle. In the conventional process, a typical 15 wt% (dissolved solids) KBL is concentrated to 45 to 70 wt% by multieffect evaporation. It has been suggested that reverse osmosis might be used to perform an initial concentration to perhaps 25 wt%. Higher concentrations may not be feasible because of the very high osmotic pressure, which at 180°F and 25 wt% solids is estimated to be 1,700 psia. The osmotic pressure for other conditions can be scaled with (14-68) using wt% instead of molality. A two-stage RO process, shown in figure, has been proposed to carry out this initial concentration for a feed rate of 1,000 lb/h at 180°F. A feed pressure of 1,756 psia is used for the first stage to yield a permeate of 0.4 wt% solids. The feed pressure to the second stage is 518 psia to produce water of 300 ppm dissolved solids and a retentate of 2.6 wt% solids. Permeate-side pressure for both stages is 15 psia. Equation (14-69) can be used to estimate membrane area, where the permeance for water can be taken as 0.0134 lb/ft2-hr-psi in conjunction with an arithmetic-mean osmotic pressure for plug flow on the feed side. Complete the material balance for the process and estimate the required membrane areas for each stage.

RO - stage 1 Concentrated KBL (25%) Feed KBL (15%) Pump #1 RO - stage 2 Pump #2 Purified water (300 ppm) Figure 14.36 Data for Exercise 14.18.

Step by Step Solution

3.40 Rating (159 Votes )

There are 3 Steps involved in it

Subject Concentration of Kraft black liquor by a twostage reverse osmosis process Given Fresh feed of 1000 lbh at 180oF and containing 15 wt dissolved ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

37-E-C-E-S-P (504).docx

120 KBs Word File