One of the old columns in your plant failed. You have been putting together a jury-rigged system

Question:

One of the old columns in your plant failed. You have been putting together a jury-rigged system to separate propane from n-butane. The column you have found is empty, so within reason you can put in as many stages as needed. It is equipped with a partial condenser and a total reboiler. The column is restricted to a maximum pressure of \(800 \mathrm{kPa}\), which means that refrigeration is needed. You have a source of refrigeration, but output is limited to \(6000 \mathrm{~kW}\). Feed is a saturated liquid at \(800 \mathrm{kPa}\) that is \(56 \mathrm{~mol} \%\) propane. Unless stated otherwise, distillate should be \(99.9 \mathrm{~mol} \%\) propane, and bottoms should be \(1.0 \mathrm{~mol} \%\) propane or less. You have more feed available than can be processed.

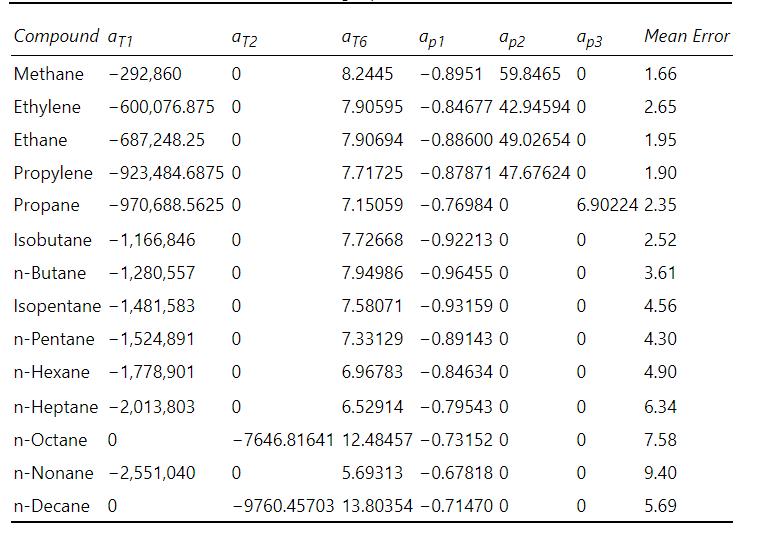

a. Generate a y-x graph at \(800 \mathrm{kPa}\) from the DePriester chart or from Table 2-5, or have Aspen Plus generate the graph. From the DePriester chart or Table 25 , find the boiling points of propane at \(800 \mathrm{kPa}\) ( \(\operatorname{set} \mathrm{K}_{\mathrm{p}}=1.0\) ) and of n-butane at \(800 \mathrm{kPa}\left(\mathrm{set} \mathrm{K}_{\mathrm{n}-\mathrm{b}}=1.0\right.\) ). The boiling range for the complete \(\mathrm{y}\)-x diagram lies between these two temperatures. Pick a temperature between the two boiling points, find \(\mathrm{K}_{\mathrm{p}}\) and \(\mathrm{K}_{\mathrm{n}-\mathrm{b}}\), calculate \(\mathrm{x}_{\mathrm{n}-\mathrm{b}}=\left(\mathrm{K}_{\mathrm{p}}-1\right) /\left(\mathrm{K}_{\mathrm{p}}-\mathrm{K}_{\mathrm{b}}\right)\), \(\mathrm{x}_{\mathrm{p}}=1-\) \(x_{n-b}, y_{p}=K_{p} x_{p}\), and \(y_{n-b}=K_{n-b} x_{n-b}\), and plot \(y_{p}\) versus \(x_{p}\). Doing this for five to ten temperatures generates the \(y\)-x graph. If Table \(2-5\) is used, then a spreadsheet works very well.

Parts \(b\) to \(\mathrm{f}\) can be done graphically (which is actually easier) or with Aspen Plus.

b. If you built a system with a very large number of stages (e.g., \(\mathrm{N}>100\) ), estimate the \(\mathrm{kmol} / \mathrm{h}\) of \(99.9 \mathrm{~mol} \%\) distillate that can be produced and \(\mathrm{kmol} / \mathrm{h}\) of feed processed (bottoms \(\leq 1.0 \mathrm{~mol} \%\) propane).

c. Repeat part b for a \(90.0 \mathrm{~mol} \%\) pure propane distillate and \(1 \%\) or less propane in the bottoms for a saturated liquid feed.

d. If the required purity of the bottoms stream is changed to \(10 \mathrm{~mol} \%\) propane, repeat part b (distillate is \(99.9 \mathrm{~mol} \%\) propane).

e. Repeat part b for a \(99.9 \mathrm{~mol} \%\) pure propane distillate and \(1 \%\) or less propane in the bottoms if the feed is a saturated vapor that is \(56 \mathrm{~mol} \%\) propane.

f. Repeat part b for a \(99.9 \mathrm{~mol} \%\) pure propane distillate and \(1 \%\) or less propane in the bottoms if the feed is a saturated liquid that is \(66 \mathrm{~mol} \%\) propane.

Data: Heat of vaporization of propane at \(800 \mathrm{kPa}\) is \(18,800 \mathrm{~kJ} / \mathrm{kmol}\) and for butane at \(800 \mathrm{kPa}\) is \(22,600 \mathrm{~kJ} / \mathrm{kmol}\) (NIST web book).

Step by Step Answer:

Separation Process Engineering Includes Mass Transfer Analysis

ISBN: 9780137468041

5th Edition

Authors: Phillip Wankat