Question: (This problem is extensive.) We want to design a separation to recover five product streams that are all (99.9^{+} mathrm{mol} %) of the respective light

(This problem is extensive.) We want to design a separation to recover five product streams that are all \(99.9^{+} \mathrm{mol} \%\) of the respective light hydrocarbons. The feed is propane \(\mathrm{z}_{\mathrm{C} 3}=0.10\), iso-butane \(\mathrm{z}_{\mathrm{iC} 4}=0.05\),normal butane \(\mathrm{z}_{\mathrm{nC} 4}=0.30\), iso-pentane \(\mathrm{z}_{\mathrm{iC} 5}=0.20\), and \(\mathrm{n}\)-pentane \(\mathrm{z}_{\mathrm{nC} 5}\) \(=0.35\). Feed is a saturated liquid at \(500 \mathrm{kPa}\), although pressure can be adjusted. Use basis \(100 \mathrm{kmol} / \mathrm{h}\). Use heuristics to develop three or four flowsheets for the separation. If possible, pick pressures for each of the four columns in your separation sequences that make the approach temperatures in the reboiler at least \(15^{\circ} \mathrm{C}\) and the condenser at least \(5^{\circ} \mathrm{C}\), or more if possible, with the condenser using cooling water, which is available at \(40^{\circ} \mathrm{C}\). You may use low-, medium-, or high-pressure steam. Report the column pressures and approach temperatures in the reboiler and condenser of each of the four columns for at least three different separation sequences. Assume each column is at a constant pressure. You will need to do a number of binary and multicomponent bubble point calculations to find appropriate temperatures, so I suggest you use Eq. (2-28) on a spreadsheet.

Eq. (2-28)

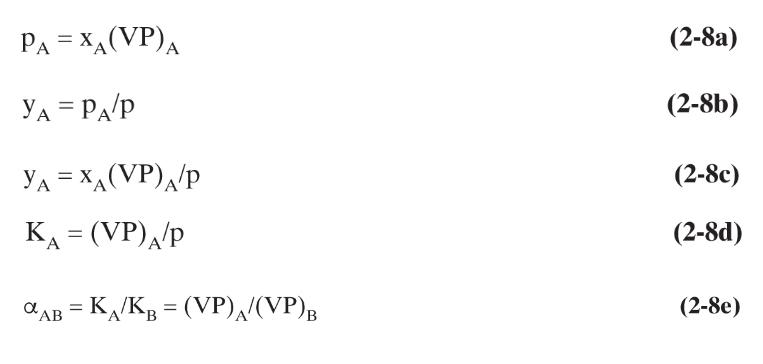

PA=XA (VP) A YA = PA/P YA=XA (VP) A/P A K = (VP) A/P AB = KA/KB = (VP)/(VP)B (2-8a) (2-8b) (2-8c) (2-8d) (2-8e)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts