Question:

Using the integration results in Example 18-7 as a base, predict the change in crystal thickness if additional feed is added for 300 more seconds to the falling-film system after a layer of crystal \(0.0034 \mathrm{~m}\) thick is attached to the heat exchanger surface.

Example 18-7

Transcribed Image Text:

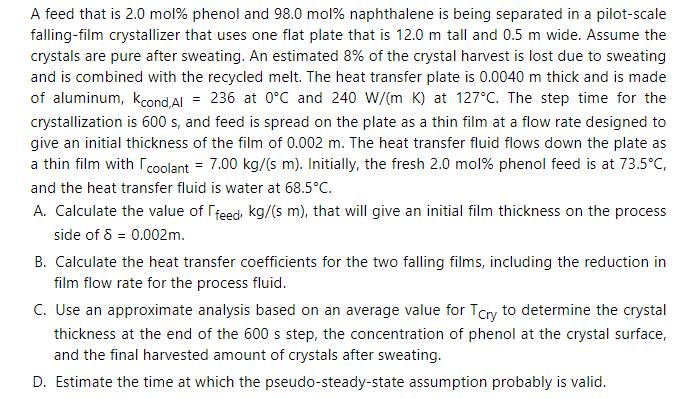

A feed that is 2.0 mol% phenol and 98.0 mol% naphthalene is being separated in a pilot-scale falling-film crystallizer that uses one flat plate that is 12.0 m tall and 0.5 m wide. Assume the crystals are pure after sweating. An estimated 8% of the crystal harvest is lost due to sweating and is combined with the recycled melt. The heat transfer plate is 0.0040 m thick and is made of aluminum, Kcond,Al = 236 at 0C and 240 W/(m K) at 127C. The step time for the crystallization is 600 s, and feed is spread on the plate as a thin film at a flow rate designed to give an initial thickness of the film of 0.002 m. The heat transfer fluid flows down the plate as a thin film with [coolant = 7.00 kg/(s m). Initially, the fresh 2.0 mol% phenol feed is at 73.5C, and the heat transfer fluid is water at 68.5C. A. Calculate the value of [feed, kg/(sm), that will give an initial film thickness on the process side of 8 = 0.002m. B. Calculate the heat transfer coefficients for the two falling films, including the reduction in film flow rate for the process fluid. C. Use an approximate analysis based on an average value for Tcry to determine the crystal thickness at the end of the 600 s step, the concentration of phenol at the crystal surface, and the final harvested amount of crystals after sweating. D. Estimate the time at which the pseudo-steady-state assumption probably is valid.