Question: As shown in the ASPEN PLUS simulation flowsheet in Fig. 21.15, liquid toluene is to be heated from 100 to (350^{circ} mathrm{F}) while liquid styrene

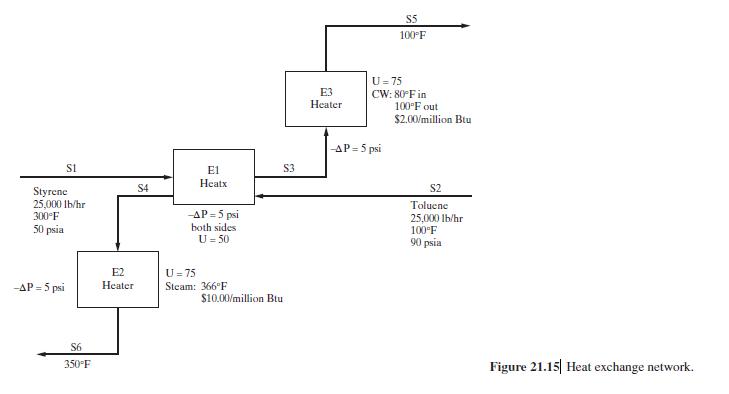

As shown in the ASPEN PLUS simulation flowsheet in Fig. 21.15, liquid toluene is to be heated from 100 to \(350^{\circ} \mathrm{F}\) while liquid styrene is to be cooled from 300 to \(100^{\circ} \mathrm{F}\). Auxiliary heat exchangers E2 and E3, which use steam and cooling water, respectively, are provided to meet the target temperatures when they cannot be achieved by the heat exchanger E1. The process is to be optimized with respect to the minimum temperature of approach in E1, which is to be between \(1^{\circ} \mathrm{F}\) and \(50^{\circ} \mathrm{F}\). The temperature of stream \(\mathrm{S} 3\) is constrained to be less than or equal to \(200^{\circ} \mathrm{F}\), and the temperature of stream S4 is constrained to be less than or equal to \(300^{\circ} \mathrm{F}\). The annualized cost is to be minimized with the return on investment, \(i_{\min }\), equal to 0.5 . All of the necessary data are included in Figure 21.15.

Figure 21.15:-

Styrene S1 25,000 lb/hr 300F 50 psia E1 $3 Heatx S4 -AP-5 psi both sides U-50 -AP = 5 psi E2 Heater U=75 Steam: 366F $10.00/million Btu S6 350F E3 Heater U=75 $5 100F CW: 80F in 100F out -AP = 5 psi $2.00/million Btu $2 Toluene 25,000 lb/hr 100F 90 psia Figure 21.15 Heat exchange network.

Step by Step Solution

3.28 Rating (154 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts