Question: Figure 20.24 shows the flowsheet for a process for the production of methanol from synthesis gas (a mixture of hydrogen, carbon monoxide, and carbon dioxide

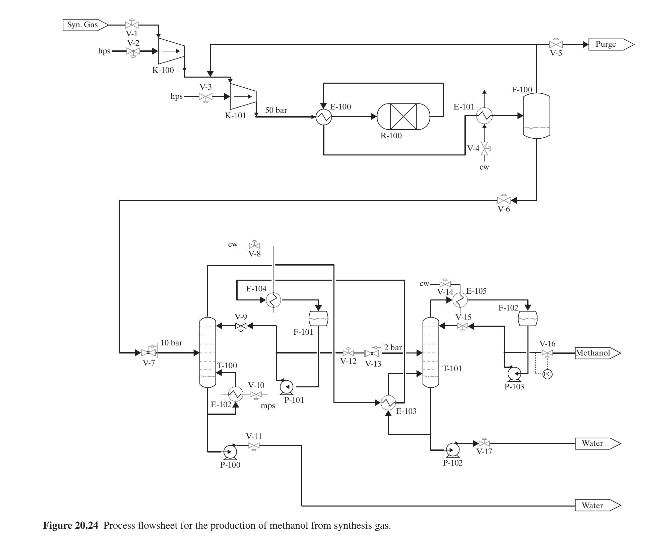

Figure 20.24 shows the flowsheet for a process for the production of methanol from synthesis gas (a mixture of hydrogen, carbon monoxide, and carbon dioxide and a small quantity of residual methane, which is inert in this process). In the process, the feed stream undergoes compression from 13 to 48 bar in compressor \(\mathrm{K}-100\), is then mixed with the recycle, and then is further compressed to 50 bar in compressor K-101. Both of the compressors are driven by turbines fed with high-pressure steam (hps). The high-pressure combined feed is heated to ignition temperature in heat exchanger E-100 and is then fed to the adiabatic reactor \(\mathrm{R}-100\), where it undergoes partial conversion to methanol and water as limited by the equilibrium conditions. The hot reactor effluent is used to preheat the feed in E-100, and is then further cooled in E-101 before being flashed in V-100. The vapor stream product from V-100 is recycled after a fraction is purged (to remove the inert methane fed in the process feed). The pressure of the liquid product stream from V-100 is reduced to \(10 \mathrm{bar}\) in pressure regulator \(\mathrm{V}-7\) and is then fed to distillation column T-100, where it is separated into a water/methanol mixture in the distillate and high-purity water in the bottoms. The distillate from T-100 undergoes further pressure reduction to 2 bar in pressure regulator \(\mathrm{V}-13\) and is then fed to a second

column, T-101, which produces high-purity methanol as the distillate and high-purity water as bottoms. This arrangement enables the partial condensation of the overhead stream in T-100 to provide all of the heat of evaporation needed in the reboiler of T-101 in heat exchanger E-103, with the remaining condensation duty provided by the cooler E-104.

You are requested to suggest a plantwide control system to enable stable operation of the process in Figure 20.24, while satisfying the following requirements:

(a) Methanol production on demand; thus, valve V-16 is already assigned to accomplish flow control of the product stream as shown in Figure 20.24.

(b) Methanol product composition on specification.

(c) Maximum methanol recovery from the process.

(d) Maximum conversion to methanol in R-100.

Syn. Cias V-1 V-2 K-100 kps 10 bar V-7 V-3 E-100 50 bar K-101 V-8 E-104 F-101 T-100 V-10 P-101 E-1022 P-100 VII R-100 E-101 F-100 V-14, ew E-105 V6 V 15 F-102, 2 har V-12 V-13 T-101 Figure 20.24 Process flowsheet for the production of methanol from synthesis gas. E-103 P-102 P-105 Purge V-16 Methanol Water V-17 Water

Step by Step Solution

3.38 Rating (151 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts