Question: Figure 20.27 shows the flowsheet for a process for the production of gasoline (mainly octane) from an olefins feed (propane, propene, and butene). The feed

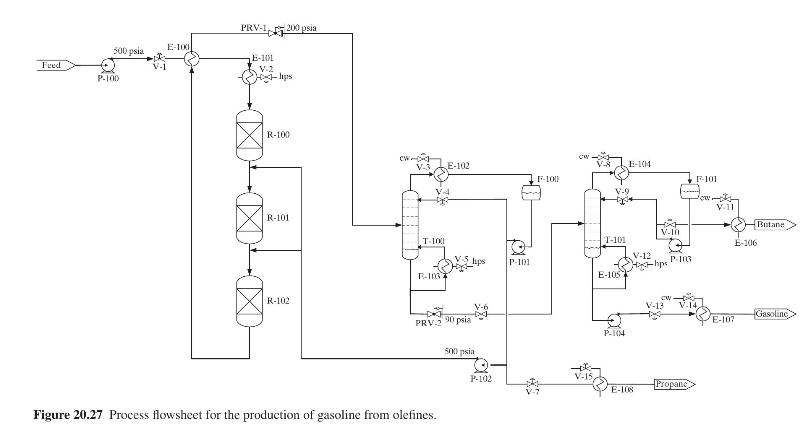

Figure 20.27 shows the flowsheet for a process for the production of gasoline (mainly octane) from an olefins feed (propane, propene, and butene). The feed to the process is heated in E-100, and then E-101, and then fed to a cascade of three PFRs operating at 500 psia where it is partially converted to gasoline (mainly octane), with temperature control affected using cold shots of propane. The hot reactor effluent stream is used to preheat the reactor feed in E-100 and is then fed to the first column, T-100, after pressure reduction to 200 psia by the pressure regulator, PRV-1, where the propane is removed as the distillate with the remaining components leaving as bottoms. Part of the propane is recycled at 500 psia for use as cold shot in the reactor cascade. The bottoms from T-100 are reduced to 90 psia by the pressure regulator, PRV-2, and then fed to the second column, T-101, which separates it into butane as distillate and gasoline as bottoms. All of the product streams are cooled using cooling water.

You are requested to suggest a plantwide control system to enable stable operation of the process providing gasoline on demand. Your solution should follow the procedure of Luyben et al. and should include the positioning of all control loops in the PFD of Figure 20.27. You are allowed to add control valves to those already in place in the PFD, but only if these are absolutely necessary to meet the requirements.

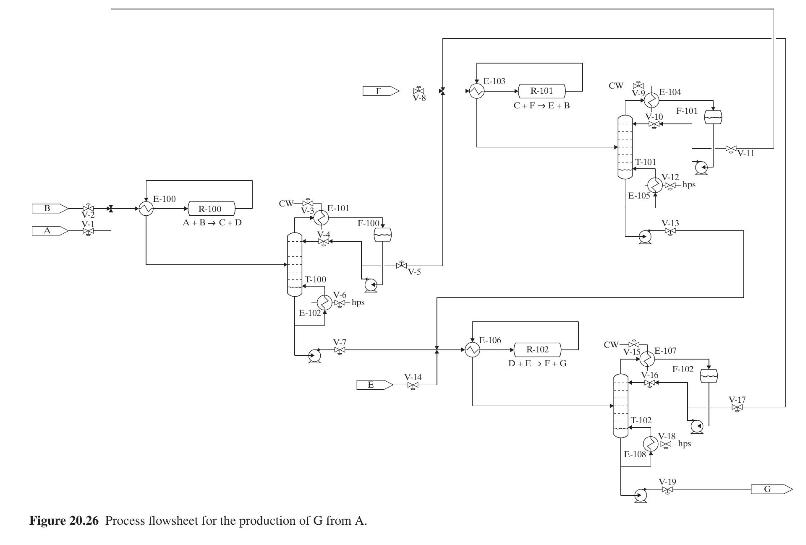

E-100 13 A R-100 A+B C D T-100 E-102 E-101 -100 V-6 -hps Figure 20.26 Process flowsheet for the production of G from A. V-14 E-103 R-101 C+FE+B CW V9E-104 F-101 V-10 T-101 V-12 -hp E-105 V-13 E-106 R-102 CW V-15E-107 DIE FIG F-102 V-16 T-102 V-18 hps T-108 V-17 V-19 G

Step by Step Solution

3.29 Rating (152 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts