Larson Company, a bike manufacturer, produces two types of bikes: mountain bikes and racing bikes. The company

Question:

Larson Company, a bike manufacturer, produces two types of bikes: mountain bikes and racing bikes. The company has two manufacturing processes: frame and bar fabrication and assembly. Once the frame and bar are produced, they are transferred to assembly, where, with other purchased parts, assembly and packing are done. Both processes acquire outside materials; however, the frame and bar fabrication process requires only metal and paint, whereas the assembly process orders a variety of parts (chains, wheels, tires, gears, gear wires, pedals, etc.).

The company currently assigns the cost of the receiving activity to the different bikes using receiving orders. Having used the ABC system for several years, the company has accumulated a good database on activities, actual and potential drivers, and activity costs.

As part of an evaluation of the ABC system, the controller computed cost formulas for ac¬

tivities and their drivers to see if evidence existed to support the assumed relationships.

Most values were respectable except for the receiving activity. Receiving orders only ex¬

plained 45% of the purchase cost activity. Having read about the effect processes can have on activity cost behavior, the controller broke the receiving activity cost into process cate¬

gories and computed two cost formulas: one for fabrication and one for assembly. Receiv¬

ing orders were used as the driver for receiving cost in the fabrication process, and number of parts was used as the driver in the assembly process. The controller was pleasantly sur¬

prised. The for receiving cost was 0.85 in the fabrication process and 0.90 in the assem¬

bly process. Based on this outcome, the controller altered the ABC assignment, using two drivers to assign receiving costs to the two bikes: purchase orders for fabrication and num¬

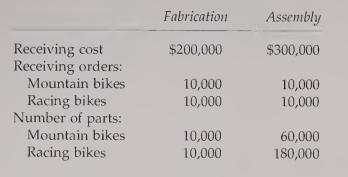

ber of parts for assembly. The information needed for assigning receiving costs is given below (100,000 units of each bike will be produced):

Required:

1. Explain why the controller used regression analysis to assess the effectiveness of the ABC system.

2. Explain why the process classification produced higher Rh than did the single plantwide activity cost formula.

3. Calculate receiving cost per unit using only purchase orders to assign costs. Repeat using purchase orders to assign costs for the fabrication process and number of parts to assign receiving costs for the assembly process. Comment on the differences.

Step by Step Answer:

Cost Management Accounting And Control

ISBN: 9780324002324

3rd Edition

Authors: Don R. Hansen, Maryanne M. Mowen