Reddy Heaters, Inc., produces insert heaters that can be used for various applications, ranging from coffeepots to

Question:

Reddy Heaters, Inc., produces insert heaters that can be used for various applications, ranging from coffeepots to submarines. Because of the wide variety of insert heaters produced, Reddy uses a job-order costing system. Product lines are differentiated by the size of the heater. In the early stages of the company’s history, sales were strong and profits steadily increased. In recent years, however, profits have been declining, and the company has been losing market share. Alarmed by the deteriorating financial position of the company, President Doug Young requested a special study to identify the problems.

Sheri Butler, the head of the Internal Audit Department, was put in charge of the study.

After two months of investigation, Sheri was ready to report her findings.

SHERI: Doug, I think we have some real concerns that need to be addressed. Production is down, employee morale is low, and the number of defective units that we have to scrap is way up. In fact, over the past several years, our scrap rate has increased from 9 percent to 15 percent of total production. And scrap is expensive. We don’t detect defective units until the end of the process. By that time, we lose everything. The nature of the product simply doesn’t permit rework. oe I have a feeling that the increased scrap rate is related to the morale problem you’ve encountered. Do you have any feel for why morale is low?

SHERI: I get the feeling that boredom is a factor. Many employees don’t feel challenged by their work, Also, with the decline in performance, they are receiving more pressure from their supervisors, which simply aggravates the problem.

DOUG: What other problems have you detected?

SHERI: Well, much of our market share has been lost to foreign competitors. The time it takes us to process an order, from time of receipt to delivery, has increased from 20 to 30 days. Some of the customers we have lost have switched to Japanese suppliers, from whom they receive heaters in less than 15 days. Added to this delay in our delivery is an increase in the number of complaints about poorly performing heaters. Our quality has definitely taken a nosedive over the past several years.

DOUG: It’s amazing that it has taken us this long to spot these problems. It’s incredible to me that the Japanese can deliver a part faster than we can, even in our more efficient days. I wonder what their secret is.

SHERI: I investigated that very issue. It appears that they can produce and deliver their heaters rapidly because they use a JIT purchasing and manufacturing system.

DOUG: Can we use this system to increase our competitive ability?

SHERI: I think so, but we’ll need to hire a consultant to tell us how to do it. Also, it might be a good idea to try it out on only one of our major product lines. I suggest the small heater line. It is having the most problems and has been showing a loss for the past two years. If JIT can restore this line to a competitive mode, then it’ll work for the other lines as well.

Within a week, Reddy Heaters hired the services of a large CPA firm. The firm sent Kim Burnham, one of its managers, to do the initial background work. After spending -

some time at the plant, Kim wrote up the following description of the small heater production process:

The various departments are scattered throughout the factory. Labor is specialized and trained to operate the machines in the respective departments. Additionally, the company has a centralized stores area that provides the raw materials for production, a centralized Maintenance Department that has responsibility for maintaining all production equipment, and a group of laborers responsible for moving the partially completed units from department to department.

Under the current method of production, small heaters pass through several departments, where each department has a collection of similar machines. The first department cuts a metal pipe into one of three lengths: three, four, or five inches long. The cut pipe is then taken to the Laser Department, where the part number is printed on the pipe. In a second department, ceramic cylinders—cut to smaller lengths than the pipe—

are wrapped with a fine wire (using a wrapping machine). The pipe and the wrapped ceramic cylinders are then taken to the Welding Department, where the wrapped ceramic cylinders are placed inside the pipe, centered, and filled with a substance that prevents electricity from reaching the metal pipe. Finally, the ends of the pipe are welded shut with two wire leads protruding from one end. This completed heater ts then transferred to the Testing Department, which uses special equipment to see if the heater functions properly.

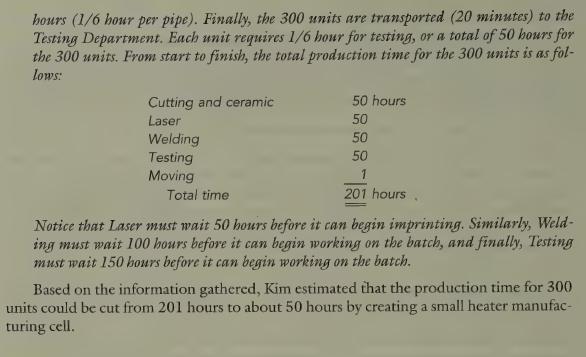

The small heaters are produced in batches of 300. It takes 50 hours to cut 300 metal pipes and prepare 300 ceramic cylinders (1/6 hour per unit, both processes occurring at the same time). After 50 hours of production time, the 300 metal pipes are transported to the Laser Department (20 minutes transport time), and the 300 ceramic cylinders are transported to the Welding Department (20 minutes transport time). In the Laser Department, it takes 50 hours to imprint the part number (1/6 hour per pipe). The 300 metal pipes are then transported to the Welding Department. In the Welding Department, the ceramic and metal pipes are joined and welded. The welding process takes 50

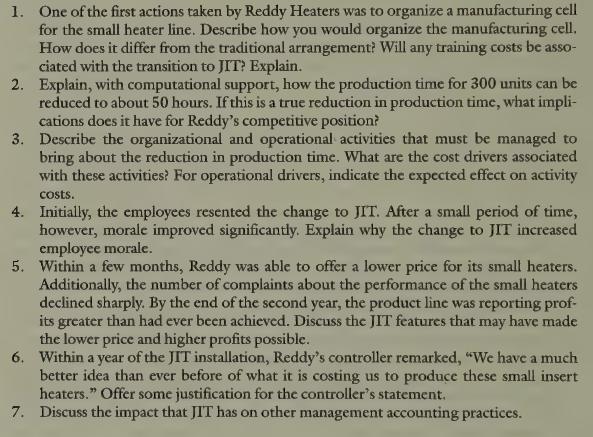

Required:

Step by Step Answer:

Introduction To Cost Accounting

ISBN: 9780538749633

1st International Edition

Authors: Don R. Hansen, Maryanne Mowen, Liming Guan, Mowen/Hansen