46. (Multiproduct; hybrid costing) Be-At-Ease Industries manufactures a series of three models of molded plastic chairs: standard

Question:

46. (Multiproduct; hybrid costing) Be-At-Ease Industries manufactures a series of three models of molded plastic chairs: standard (can be stacked), deluxe (with arms), and executive (with arms and padding); all are variations of the same design. The company uses batch manufacturing and has a hybrid costing system.

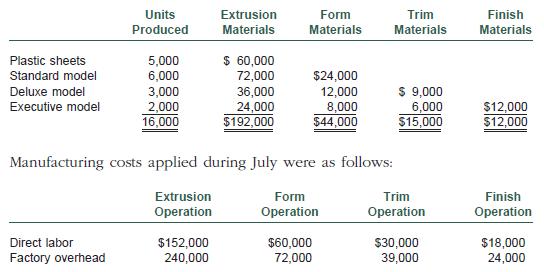

Be-At-Ease has an extrusion operation and subsequent operations to form, trim, and finish the chairs. Plastic sheets are produced by the extrusion operation, some of which are sold directly to other manufacturers. During the forming operation, the remaining plastic sheets are molded into chair seats and the legs are added; the standard model is sold after this operation. During the trim operation, the arms are added to the deluxe and executive models and the chair edges are smoothed. Only the executive model enters the finish operation where the padding is added. All of the units produced receive the same steps within each operation.

The July production run had a total manufacturing cost of $898,000. The units of production and direct material costs incurred were as follows:

a. For each product produced by Be-At-Ease during July, determine the 1. Unit cost.

2. Total cost.

Be sure to account for all costs incurred during the month, and support your answer with appropriate calculations.

b. Without prejudice to your answer in part (a), assume that 1,000 units of the deluxe model remained in Work in Process Inventory at the end of the month. These units were 100 percent complete in the trim operation.

Determine the value of the 1,000 units of the deluxe model in Be-At-Ease’s Work in Process Inventory at the end of July.

Step by Step Answer:

Cost Accounting Traditions And Innovations

ISBN: 9780324180909

5th Edition

Authors: Jesse T. Barfield, Cecily A. Raiborn, Michael R. Kinney