CAL manufactures and sells solar panels for garden lights. Components are bought in and assembled into metal

Question:

CAL manufactures and sells solar panels for garden lights. Components are bought in and assembled into metal frames that are machine manufactured by CAL. There are a number of alternative suppliers of these solar panels. Some of CAL’s competitors charge a lower price, but supply lower quality panels; whereas others supply higher quality panels than CAL but for a much higher price.

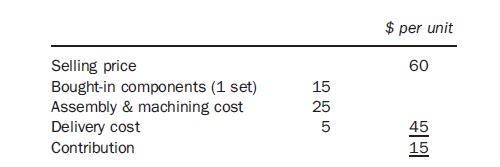

CAL is preparing its budgets for the coming year and has estimated that the market demand for its type of solar panels will be 100 000 units and that its share will be 20 000 units (i.e. 20 per cent of the available market). The standard cost details of each solar panel are as follows:

An analysis of CAL’s recent performance revealed that 2 per cent of the solar panels supplied to customers were returned for free replacement, because the customer found that they were faulty.

Investigation of these returned items shows that the components had been damaged when they had been assembled into the metal frame. These returned panels cannot be repaired and have no scrap value. If the supply of faulty solar panels to customers could be eliminated then, due to improved customer perception, CAL’s market share would increase to 25 per cent.

Required:

(a) Explain, with reference to CAL, quality conformance costs and quality non-conformance costs and the relationship between them.

(b) Assuming that CAL continues with its present systems and that the percentage of quality failings is as stated above:

(i) Calculate, based on the budgeted figures and sales returns rate, the total relevant costs of quality for the coming year.

(ii) Calculate the maximum saving that could be made by implementing an inspection process for the solar panels, immediately before the goods are delivered.

Step by Step Answer: