Using the figure in the Application A Semiconductor Integrated Circuit Isoquant, show that as the firm employs

Question:

Using the figure in the Application "A Semiconductor Integrated Circuit Isoquant," show that as the firm employs additional fixed-proportion technologies, the firm's overall isoquant approaches a smooth curve.

Data From Application "A Semiconductor Integrated Circuit Isoquant":-

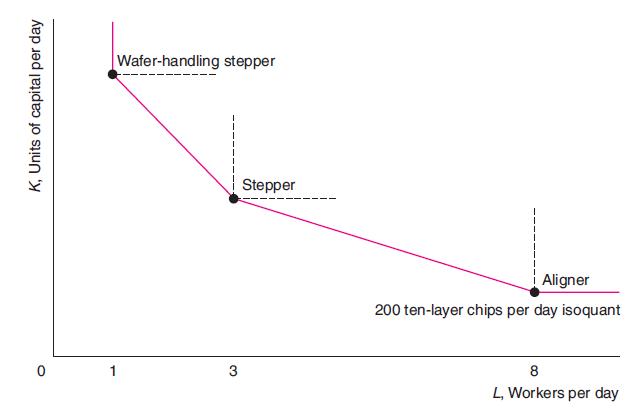

We can show why isoquants curve away from the origin by deriving an isoquant for semiconductor integrated circuits (ICs, or “chips”)—the “brains” of computers and other electronic devices. Semiconductor manufacturers buy silicon wafers and then use labor and capital to produce the chips. A chip consists of multiple layers of silicon wafers. A key step in the production process is to line up these layers. Three alternative alignment technologies are available, using different combinations of labor and capital. In the least capital-intensive technology, employees use machines called aligners, which require workers to look through microscopes and line up the layers by hand. To produce 200 ten-layer chips per day takes 8 workers using 8 aligners. A second, more capital-intensive technology uses machines called steppers. The stepper aligns the layers automatically. This technology requires less labor: To produce 200 ten-layer chips per day requires 3 workers and 6 steppers. A third, even more capital-intensive technology combines steppers with water handling equipment, which further reduces the amount of labor needed. One worker using 4 steppers with wafer-handling capabilities can manufacture 200 tenlayer chips per day. In the diagram, the vertical axis measures the amount of capital used. An aligner represents less capital than a basic stepper, which in turn is less capital than a stepper with wafer-handling capabilities. All three technologies use labor and capital in fixed proportions. The diagram shows the three right-angle isoquants corresponding to each of these three technologies.

Some plants employ a combination of these technologies, so that some workers use one type of machine while others use different types. By doing so, the plant can produce using intermediate combinations of labor and capital, as the solid-line, kinked isoquant illustrates. The firm does not use a combination of the aligner and the wafer-handling stepper technologies because those combinations are less efficient than using the basic stepper: The line connecting the aligner and waferhandling stepper technologies is farther from the origin than the lines between those technologies and the basic stepper technology. New processes are constantly being invented. As they are introduced, the isoquant will have more and more kinks (one for each new process) and will begin to resemble the smooth, convex isoquants we’ve been drawing.

Step by Step Answer: