Bluegrass Irrigation Services (BIS) in Lexington, Kentucky, provides a wide variety of services to meet customer needs.

Question:

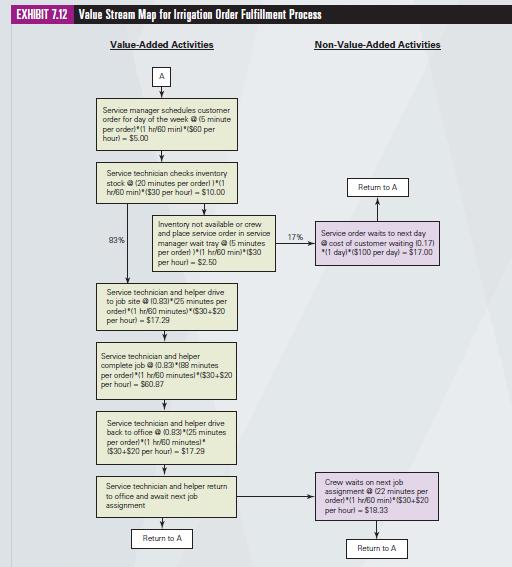

Bluegrass Irrigation Services (BIS) in Lexington, Kentucky, provides a wide variety of services to meet customer needs. These services include installation of lawn and tree irrigation equipment for residential and commercial customers, landscaping services, low voltage lightning, and lawn drainage. During the winter months, BIS provides snow removal services and sells dry firewood. The family business employs 22 people and provides services in the greater Lexington area. The staff includes two office managers, one office assistant, one service manager, one warehouse parts specialist, nine certified service technicians, and six service technician helpers. BSI has two summer job openings for service technician helpers. It owns one office truck and nine technician trucks, all with GPS capability. The service manager, Luciana Anderson, had taken an online process mapping course at a local college. She and an office manager drew a preliminary value-added map, as shown in Exhibit 7.12. With a pile of notes on her desk requesting customer appointments, she scheduled each job for a specific day of the week. A service technician would then check BSI inventory to assess if the proper plastic pipe, fittings, and parts were available to complete the job. A job cannot be started unless all parts specific to that job are available. The average time at the job site was 88 minutes; however, the standard deviation of this work time was high, so job time estimates were erratic. Many things contributed to erratic work times such as the customer not being home, no access to the main water line, large rocks and hard soil, not knowing exactly where property boundaries are located, and customer’s additions or deletions from the original job estimate. Luciana estimated that the cost of promising a customer that BSI would be there in one day, yet showing up three days later, is \($100\) per day or \($300\) in lost goodwill, future referrals, and sales. Her pay rate is \($60\) per hour, that of the service technician is \($30\) per hour, and that of the service technician helper is \($20\) per hour. Based on Exhibit 7.12, Luciana computed the following summary information.

Total value-added time per job = 5 + 20 + 5 +25 + 88 + 25 = 168 minutes Total value-added cost per job = \($5\) + \($10\) + \($2.50\) + \($17.29\) + \($60.87\) + \($17.29\) = \($112.95\) Total non-value-added cost per job = \($17\) + \($18.33\) = \($35.33\) Total value- and non-value added cost per job

= \($148.28\) Luciana realized the value stream map was not a perfect depiction of processing customer service requests, but it was a good basis for discussion. For example, demand for their lawn care services started to decrease in October and did not resume until April. She tried to keep all employees busy with snow removal, wood chopping and splitting, and wood delivery services. However, about two-thirds of the service technician helpers left BSI in the winter for other jobs or to rest and relax.

Case Questions for Discussion:

1. How would you classify their business—a project, job shop, flow shop, or continuous flow process? Explain your reasoning.

2. Answer each of the eight process analysis questions in Section 7-6 for BSI’s current service order fulfillment process. (The case does not provide enough information for a detailed answer to each question, so focus on the big picture.)

3. What are your final recommendations for improving BSI’s service order process and other aspects of their business? Draw a revised value stream map depicting your final recommended process.

Step by Step Answer:

Operations And Supply Chain Management

ISBN: 9780357901649

3rd Edition

Authors: David A. Collier; James Evans