Manyata Sachdev, a recent graduate from a U.S. west coast business school, has worked for Jameson Technology

Question:

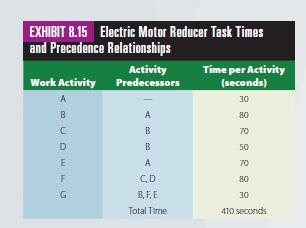

Manyata Sachdev, a recent graduate from a U.S. west coast business school, has worked for Jameson Technology for four years. She had worked in sales and logistics, and now they wanted her to work in production to broaden her company experience. Ms. Sachdev was a high achiever and part of Jameson’s young executive development program. She majored in finance with a minor in marketing and a second minor in logistics. Jameson Technology won a supplier contract to assembly 100,000 electric motor reducers this first year of production. A reducer is like a transmission for internal combustion engines, but for electric vehicles. It transfers the electric motor power to the wheel. The electric motor has a much higher revolutions per minute (RPM) than that of an internal combustion engine. The transmission and the reducer accomplish the same task—they transfer the RPM to the wheel to match the driving circumstances. The factory manager assigned Ms. Sachdev, along with three engineers, to set up an assembly line for manufacturing the reducers. The assembly team gave Ms. Sachdev two chapters to read and one article to learn the concepts and methods of assembly line balancing. The team decided initially to break the work content down into eight major work activities and times, as shown in Exhibit 8.15. Besides helping set up the assembly line, the factory manager wanted Ms. Sachdev to estimate preliminary fixed and variable assembly cost per reducer. Jameson used broad estimates of these unit costs to bag the contract, but now contract profitability depended on making the assembly line more and more efficient during the year. Costs were directly related to how well the assembly line is designed and managed.

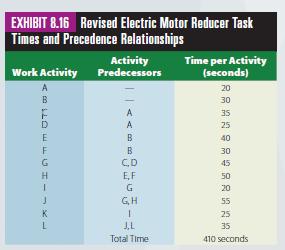

Case Questions for Discussion:

1. Draw the precedence diagram and calculate the cycle time based on working two shifts or 16 hours per day for 250 days a year using the data in Exhibit8.15.

2. Balance the assembly line for Exhibit 8.15 using the

(a) longest task time first processing rule, and

(b) the shortest task time first processing rule. Be sure to follow the steps carefully for the longesttask- time rule in Section 8-2b and adjust it for part (b). How efficient are these two assembly line balances? Do you think Jameson will make money using these two balances? Explain.

3. Suppose the assembly team didn’t like the assembly line efficiencies and unit costs for the balances in Question 2. They broke down the work activities in Exhibit 8.15 into more detail, as shown in Exhibit 8.16. Answer Questions 1 and 2 for this revised set of work activities and times. Compare your answers with the balances you obtained using Exhibit 8.15.

Step by Step Answer:

Operations And Supply Chain Management

ISBN: 9780357901649

3rd Edition

Authors: David A. Collier; James Evans