Glen County manages a waste-to-energy facility that burns 2,000 tons of trash per day and generates over

Question:

Glen County manages a waste-to-energy facility that burns 2,000 tons of trash per day and generates over \($20\) million in electricity annually while costing state and local taxpayers \($24\) million to operate. The trash burning facility also generates about \($1\) million a year from recyclable materials; mainly ferrous metals. Eighty-five percent of the electricity is sold to large electrical providers, and the rest is used to power the Glen County facility and adjacent government buildings. Prior to construction of the trash-burning facility, the pre-sorted trash went to a landfill. In 2022, 75 trash-burning facilities operated in the United States. Methane and other gas emissions had become a major problem, resulting in citations from the United States Environmental Protection Agency (EPA) and other government agencies. The supply chain for burnable trash begins when residents sort their trash according to certain rules. All residents have two trash containers—one for food waste and nonrecyclable materials, and a second container for paper, cardboard, aluminum cans, grocery bags, glass, plastics, junk mail, and so on. Waste refuse trucks pick up the recyclable trash and dump it into storage pits at the waste facility. Cranes mix the waste in the pit. Employees constantly scan the pit for items that can break equipment and should not be burned, such as metal bars, steel shelves, light bulbs, and tires. The cranes lift the sorted trash up and deposit it into a feed chute that leads to the furnace. A jam in the equipment normally stops the entire process for about two hours. During this downtime, natural gas is used to keep the combustion going. Inside steel tubes, heat arising from the combustion of the trash coverts water into steam. The superheater steam creates a high pressure that drives a turbine generator to produce electricity. The steam cools and enters an air pollution system. Using lime slurry, dry scrubbers neutralize any acid-forming gases, such as sulfur oxides, lead, mercury, and hydrogen chloride. All gases travel through filters in a room called the bag house. Over 99 percent of the particulates are removed from the air and gases. Huge fans blow the air away from the facility and send it out through a chimney stack. During the combustion, ash makes its way out of the furnace and falls into an ash discharger. Magnets remove scrap iron from the ash before the ash falls into hoppers. The ash is sprayed with water and transported by conveyors to be loaded onto trucks. They take the ash residue to the landfill. For every ton of burnable trash, about one-fourth of it goes into the landfill as ash. Several steps are taken to protect the ground water from contamination. Glen County is going to present its case for \($50\) million in tax-free municipal bonds to several big financial institutions soon. The Glen County Solid Waste Commission asked you to answer the following questions as a basis for the municipal bond initiative Case Questions for Discussion:

1. How would you characterize this waste-to-energy supply chain in terms of

(a) efficient-responsive,

(b) push-pull,

(c) backward-forward integration, and

(d) location criteria?

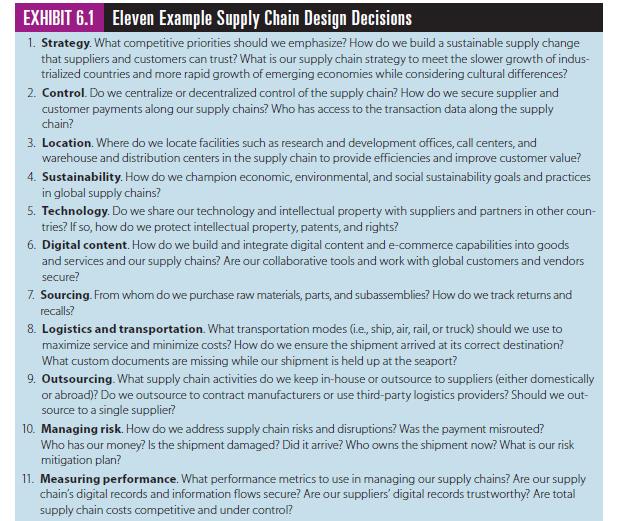

2.Write a short statement on each of the 11 decisions in Exhibit 6.1 that Glen County might use in their government waste-to-energy handouts and municipal bond prospectus. What might be a positive goal, strategy, practice, or initiative that Glen County can pursue for its waste-to-energy facilities?

Step by Step Answer:

Operations And Supply Chain Management

ISBN: 9780357901649

3rd Edition

Authors: David A. Collier; James Evans