Carolyn Roberts is the operations manager of the machine shop of Reliable Manufacturing. She has to schedule

Question:

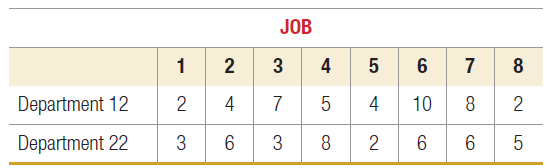

Carolyn Roberts is the operations manager of the machine shop of Reliable Manufacturing. She has to schedule eight jobs that are to be sent to final assembly for an important customer order. Currently, all eight jobs are in department 12 and must be next routed to department 22. All jobs arrived at the same time. Jason Mangano, supervisor for department 12, is concerned about keeping his inventory low and is adamant about processing the jobs through his department on the basis of shortest processing time. Pat Mooney, supervisor for department 22, pointed out that if Mangano were more flexible the orders could be finished and shipped earlier. The processing times (in days) for each job in each department follow:

a. Determine a schedule for the operation in each department. Use the SPT priority sequencing rule for department 12 and the same sequence for department 22. What is the average flow time for department 12? What is the makespan through both departments? What is the total number of jobdays spent in the system?

b. Find a schedule that will minimize the makespan through both departments, and then calculate the average flow time for department 12. What is the total number of job-days spent in the system?

c. Discuss the trade-offs represented by these two schedules. What implications do they have for centralized scheduling?

Step by Step Answer:

Operations Management Processes and Supply Chains

ISBN: 978-0134741062

12th edition

Authors: Lee J. Krajewski, Manoj K. Malhotra, Larry P. Ritzman