Question

Allison Ltd located in Figtree is producing and selling Clothes Dryers and expecting to produce 20 000 units of Dryers. Currently, Allison Ltd makes the

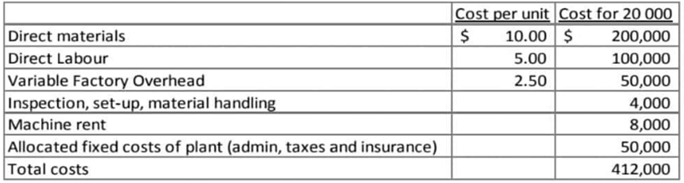

Allison Ltd located in Figtree is producing and selling Clothes Dryers and expecting to produce 20 000 units of Dryers. Currently, Allison Ltd makes the motor in-house for its Dryers. The cost data to make the Motors for 20 000 Dryers are as follows:

Recently, Allison Ltd received a call from an outside supplier who offered to supply the motors at $18.50 per motor. The management of Allison Ltd consider this offer and starts to obtain more data before make the decision. Accordingly, the following information is available:

(a) Inspection, set-up and materials handling costs vary with the number of batches in which the motors are produced. Allison Ltd produces the motors in batch sizes of 1 000 units. Allison Ltd will produce the 20 000 units in 20 batches.

(b) Allison Ltd rents the machine used to make the motors. If Allison Ltd buys all of its motors from the outside supplier, it does not need to pay rent on this machine.

Required (show your working):

(1) Assume that Allison Ltd purchases the motors from the outside supplier, the facility where the motors 10 mark are currently made will remain idle (unused). On the basis of financial considerations alone, should Allison Ltd accept or reject the offer from the outside vendor at the anticipated production (and sales) volume 20 000 units?

(2) Assume that, if the motors are purchase from outside, the facilities where the motors are currently 10 mark made will be used to make a new product that will bring contribution of $120 000. An additional tooling costs of $100 000 would be incurred to make this new product. On the basis of financial considerations alone, should Allison Ltd make or buy the motors, assuming that 20 000 dryers are produced and sold?

(3) The sales manager of Allison Ltd is concerned that the estimate of 20 000 units may be high and 10 mark believe that only 16 000 units will be sold. Production will be cut back, freeing up work space. This space can be used to add the additional components whether Allison Ltd buys the motors or makes them in-house. At this lower output, Allison Ltd will produce the motors in 16 batches of 1 000 units each. On the basis of financial considerations alone, should Allison Ltd purchase the motors from the outsider suppliers?Direct materials Direct Labour Variable Factory Overhead Inspection, set-up, material handling Machine rent Allocated fixed costs of plant (admin, taxes and insurance) Total costs Cost per unit Cost for 20 000 $ 10.00 $ 5.00 2.50 200,000 100,000 50,000 4,000 8,000 50,000 412,000

Step by Step Solution

There are 3 Steps involved in it

Step: 1

1 Direct material 1020000 200000 Direct labour 520000 100000 Variable factory overhead 25020000 5000...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started