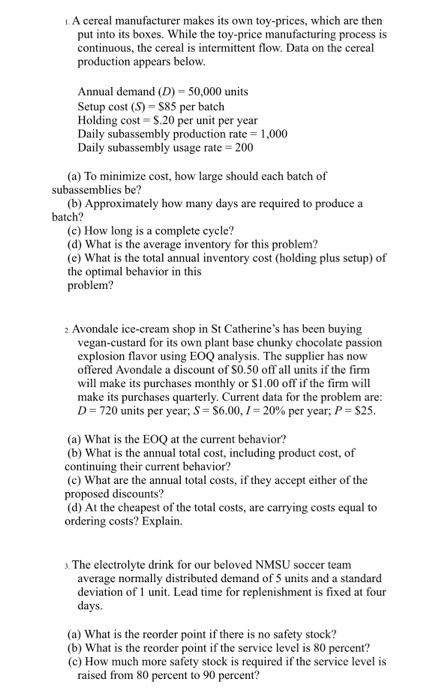

1. A cereal manufacturer makes its own toy-prices, which are then put into its boxes. While the toy-price manufacturing process is continuous, the cereal is intermittent flow. Data on the cereal production appears below. Annual demand (D)=50,000 units Setup cost (S)=$85 per batch Holding cost =$.20 per unit per year Daily subassembly production rate =1,000 Daily subassembly usage rate =200 (a) To minimize cost, how large should each batch of subassemblies be? (b) Approximately how many days are required to produce a batch? (c) How long is a complete cycle? (d) What is the average inventory for this problem? (e) What is the total annual inventory cost (holding plus setup) of the optimal behavior in this problem? 2. Avondale ice-cream shop in St Catherine's has been buying vegan-custard for its own plant base chunky chocolate passion explosion flavor using EOQ analysis. The supplier has now offered Avondale a discount of $0.50 off all units if the firm will make its purchases monthly or $1,00 off if the firm will make its purchases quarterly. Current data for the problem are: D=720 units per year; S=$6.00,I=20% per year; P=$25. (a) What is the EOQ at the current behavior? (b) What is the annual total cost, including product cost, of continuing their current behavior? (c) What are the annual total costs, if they accept either of the proposed discounts? (d) At the cheapest of the total costs, are carrying costs equal to ordering costs? Explain. 1. The electrolyte drink for our beloved NMSU soccer team average normally distributed demand of 5 units and a standard deviation of 1 unit. Lead time for replenishment is fixed at four days. (a) What is the reorder point if there is no safety stock? (b) What is the reorder point if the service level is 80 percent? (c) How much more safety stock is required if the service level is raised from 80 percent to 90 percent? 1. A cereal manufacturer makes its own toy-prices, which are then put into its boxes. While the toy-price manufacturing process is continuous, the cereal is intermittent flow. Data on the cereal production appears below. Annual demand (D)=50,000 units Setup cost (S)=$85 per batch Holding cost =$.20 per unit per year Daily subassembly production rate =1,000 Daily subassembly usage rate =200 (a) To minimize cost, how large should each batch of subassemblies be? (b) Approximately how many days are required to produce a batch? (c) How long is a complete cycle? (d) What is the average inventory for this problem? (e) What is the total annual inventory cost (holding plus setup) of the optimal behavior in this problem? 2. Avondale ice-cream shop in St Catherine's has been buying vegan-custard for its own plant base chunky chocolate passion explosion flavor using EOQ analysis. The supplier has now offered Avondale a discount of $0.50 off all units if the firm will make its purchases monthly or $1,00 off if the firm will make its purchases quarterly. Current data for the problem are: D=720 units per year; S=$6.00,I=20% per year; P=$25. (a) What is the EOQ at the current behavior? (b) What is the annual total cost, including product cost, of continuing their current behavior? (c) What are the annual total costs, if they accept either of the proposed discounts? (d) At the cheapest of the total costs, are carrying costs equal to ordering costs? Explain. 1. The electrolyte drink for our beloved NMSU soccer team average normally distributed demand of 5 units and a standard deviation of 1 unit. Lead time for replenishment is fixed at four days. (a) What is the reorder point if there is no safety stock? (b) What is the reorder point if the service level is 80 percent? (c) How much more safety stock is required if the service level is raised from 80 percent to 90 percent