Answered step by step

Verified Expert Solution

Question

1 Approved Answer

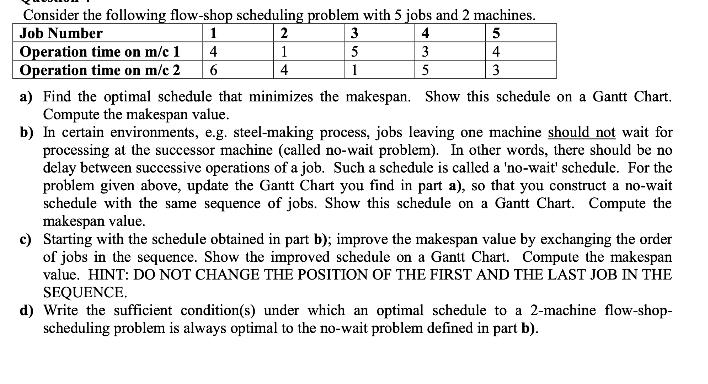

1 Consider the following flow-shop scheduling problem with 5 jobs and 2 machines. Job Number 2 3 4 5 Operation time on m/c 1

1 Consider the following flow-shop scheduling problem with 5 jobs and 2 machines. Job Number 2 3 4 5 Operation time on m/c 1 4 1 5 3 Operation time on m/c 2 6 4 1 5 4 3 a) Find the optimal schedule that minimizes the makespan. Show this schedule on a Gantt Chart. Compute the makespan value. b) In certain environments, e.g. steel-making process, jobs leaving one machine should not wait for processing at the successor machine (called no-wait problem). In other words, there should be no delay between successive operations of a job. Such a schedule is called a 'no-wait' schedule. For the problem given above, update the Gantt Chart you find in part a), so that you construct a no-wait schedule with the same sequence of jobs. Show this schedule on a Gantt Chart. Compute the makespan value. c) Starting with the schedule obtained in part b); improve the makespan value by exchanging the order of jobs in the sequence. Show the improved schedule on a Gantt Chart. Compute the makespan value. HINT: DO NOT CHANGE THE POSITION OF THE FIRST AND THE LAST JOB IN THE SEQUENCE. d) Write the sufficient condition(s) under which an optimal schedule to a 2-machine flow-shop- scheduling problem is always optimal to the no-wait problem defined in part b).

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started