Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1. What is the Rate of Return for the 3 options?Based on the MARR percentage provided, are any of the 3 options viable? Precision Gears

1. What is the Rate of Return for the 3 options?Based on the MARR percentage provided, are any of the 3 options viable?

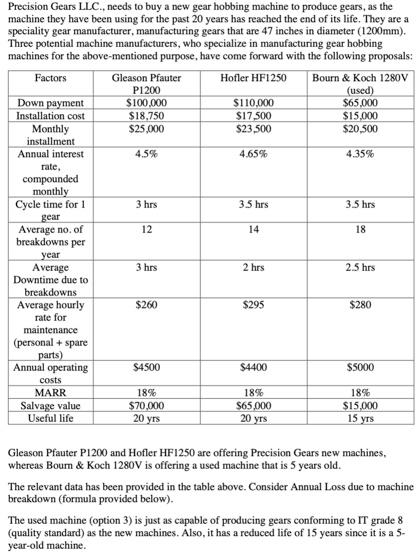

Precision Gears LLC., needs to buy a new gear hobbing machine to produce gears, as the machine they have been using for the past 20 years has reached the end of its life. They are a speciality gear manufacturer, manufacturing gears that are 47 inches in diameter (1200mm). Three potential machine manufacturers, who specialize in manufacturing gear bobbing machines for the above-mentioned purpose, have come forward with the following proposals: Factors Gleason Pfauter Hofler HF1250 Bourn & Koch 1280V P1200 (used) Down payment $100,000 $110.000 $65.000 Installation cost $18.750 $17.500 $15,000 Monthly $25,000 $23.500 $20,500 installment Annual interest 4.5% 4.65% 4.35% rate, compounded monthly Cycle time for 1 3 hrs 3.5 hrs 3.5 hrs gear Average no. of 12 14 18 breakdowns per year Average 3 hrs 2 hrs 2.5 hrs Downtime due to breakdowns Average hourly $260 $295 $280 rate for maintenance (personal + spare parts) Annual operating $4500 $4400 $5000 costs MARR 18% 18% 18% Salvage value $70,000 $65,000 $15.000 Useful life 20 yrs 20 yrs 15 yrs Gleason Pfauter P1200 and Hofler HF1250 are offering Precision Gears new machines, whereas Boum & Koch 1280V is offering a used machine that is 5 years old. The relevant data has been provided in the table above. Consider Annual Loss due to machine breakdown (formula provided below). The used machine (option 3) is just as capable of producing gears conforming to IT grade 8 (quality standard) as the new machines. Also, it has a reduced life of 15 years since it is a 5- year-old machine Precision Gears LLC., needs to buy a new gear hobbing machine to produce gears, as the machine they have been using for the past 20 years has reached the end of its life. They are a speciality gear manufacturer, manufacturing gears that are 47 inches in diameter (1200mm). Three potential machine manufacturers, who specialize in manufacturing gear bobbing machines for the above-mentioned purpose, have come forward with the following proposals: Factors Gleason Pfauter Hofler HF1250 Bourn & Koch 1280V P1200 (used) Down payment $100,000 $110.000 $65.000 Installation cost $18.750 $17.500 $15,000 Monthly $25,000 $23.500 $20,500 installment Annual interest 4.5% 4.65% 4.35% rate, compounded monthly Cycle time for 1 3 hrs 3.5 hrs 3.5 hrs gear Average no. of 12 14 18 breakdowns per year Average 3 hrs 2 hrs 2.5 hrs Downtime due to breakdowns Average hourly $260 $295 $280 rate for maintenance (personal + spare parts) Annual operating $4500 $4400 $5000 costs MARR 18% 18% 18% Salvage value $70,000 $65,000 $15.000 Useful life 20 yrs 20 yrs 15 yrs Gleason Pfauter P1200 and Hofler HF1250 are offering Precision Gears new machines, whereas Boum & Koch 1280V is offering a used machine that is 5 years old. The relevant data has been provided in the table above. Consider Annual Loss due to machine breakdown (formula provided below). The used machine (option 3) is just as capable of producing gears conforming to IT grade 8 (quality standard) as the new machines. Also, it has a reduced life of 15 years since it is a 5- year-old machineStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started