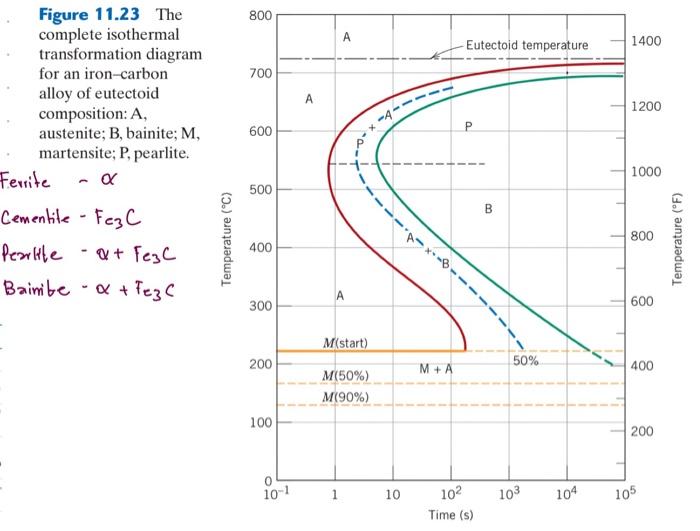

1.18 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 11.23), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In each case assume that the specimen begins at 760C (1400F) and that it has been held at this temperature long enough to have achieved a complete and homogeneous austenitic structure. (a) Cool rapidly to 700C(1290F), hold for 104s, then quench to room temperature. (b) Reheat the specimen in part (a) to 700C (1290F) for 20h. (c) Rapidly cool to 600C(1110F), hold for 4s, rapidly cool to 450C(840F), hold for 10s, then quench to room temperature. (d) Cool rapidly to 400C(750F), hold for 2s, then quench to room temperature. (e) Cool rapidly to 400C(750F), hold for 20s, then quench to room temperature. (f) Cool rapidly to 400C(750F), hold for 200s, then quench to room temperature. (g) Rapidly cool to 575C(1065F), hold for 20s, rapidly cool to 350C(660F), hold for 100s, then quench to room temperature. (h) Rapidly cool to 250C(480F), hold for 100s, then quench to room temperature in water. Reheat to 315C(600F) for 1h and slowly cool to room temperature. Figure 11.23 The complete isothermal transformation diagram for an iron-carbon alloy of eutectoid composition: A, austenite; B, bainite; M, martensite; P, pearlite. Ferrite Cementite - Fe3C Peritite Q+Fe3C Baimibe +Fe3C 1.18 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 11.23), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In each case assume that the specimen begins at 760C (1400F) and that it has been held at this temperature long enough to have achieved a complete and homogeneous austenitic structure. (a) Cool rapidly to 700C(1290F), hold for 104s, then quench to room temperature. (b) Reheat the specimen in part (a) to 700C (1290F) for 20h. (c) Rapidly cool to 600C(1110F), hold for 4s, rapidly cool to 450C(840F), hold for 10s, then quench to room temperature. (d) Cool rapidly to 400C(750F), hold for 2s, then quench to room temperature. (e) Cool rapidly to 400C(750F), hold for 20s, then quench to room temperature. (f) Cool rapidly to 400C(750F), hold for 200s, then quench to room temperature. (g) Rapidly cool to 575C(1065F), hold for 20s, rapidly cool to 350C(660F), hold for 100s, then quench to room temperature. (h) Rapidly cool to 250C(480F), hold for 100s, then quench to room temperature in water. Reheat to 315C(600F) for 1h and slowly cool to room temperature. Figure 11.23 The complete isothermal transformation diagram for an iron-carbon alloy of eutectoid composition: A, austenite; B, bainite; M, martensite; P, pearlite. Ferrite Cementite - Fe3C Peritite Q+Fe3C Baimibe +Fe3C