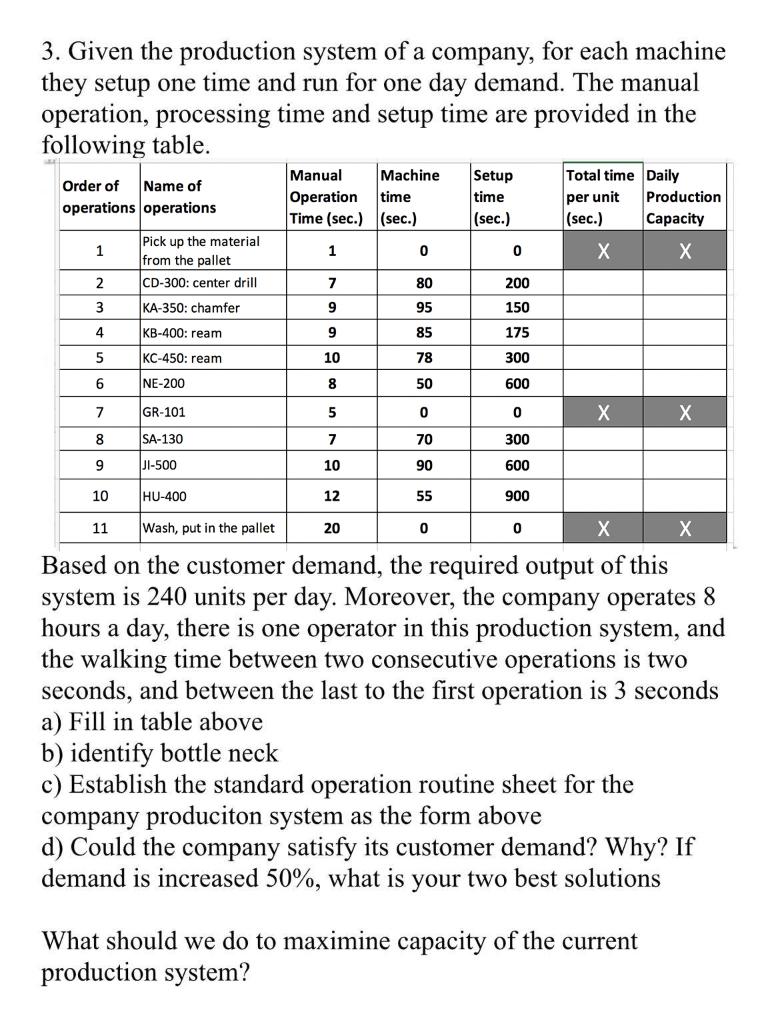

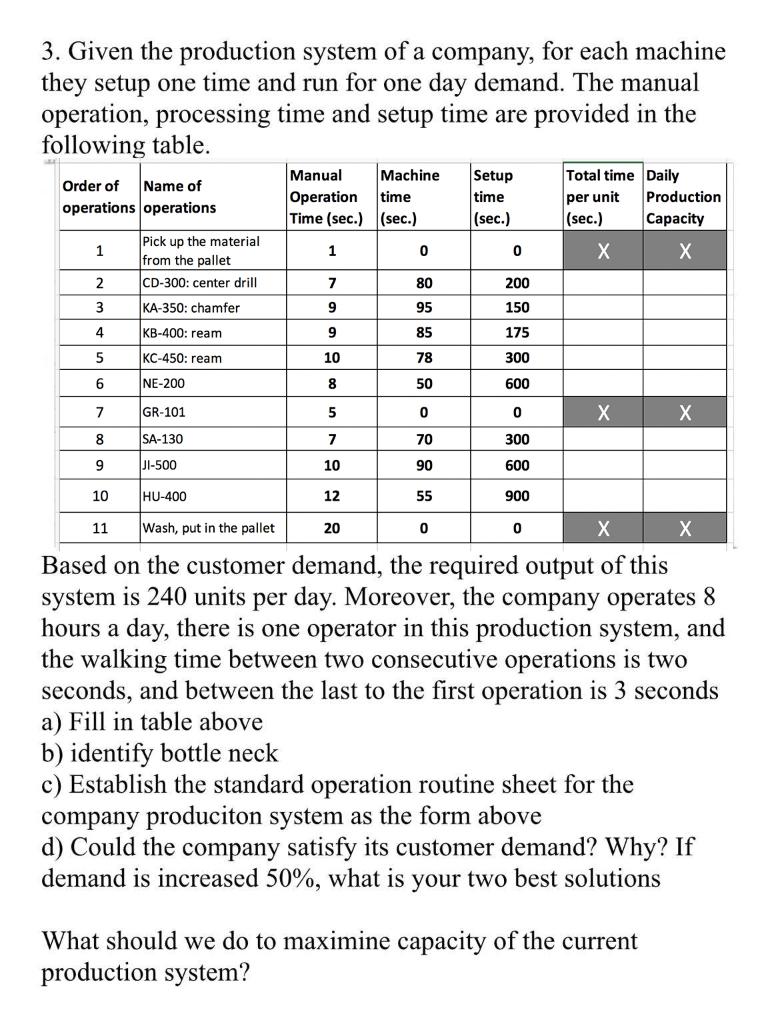

3. Given the production system of a company, for each machine they setup one time and run for one day demand. The manual operation, processing time and setup time are provided in the following table. Machine Setup Total time Daily Name of Operation time per unit Production operations operations Time (sec.) (sec.) (sec.) (sec.) Capacity Pick up the material from the pallet CD-300: center drill KA-350: chamfer Manual Order of time 1 1 0 0 2 7 80 200 3 9 95 150 4 KB-400: ream 9 85 175 5 KC-450: ream 10 78 300 6 NE-200 8 50 600 7 GR-101 5 0 0 8 SA-130 7 70 300 9 JI-500 10 90 600 10 HU-400 12 55 900 11 Wash, put in the pallet 20 0 0 Based on the customer demand, the required output of this system is 240 units per day. Moreover, the company operates 8 hours a day, there is one operator in this production system, and the walking time between two consecutive operations is two seconds, and between the last to the first operation is 3 seconds a) Fill in table above b) identify bottle neck c) Establish the standard operation routine sheet for the company produciton system as the form above d) Could the company satisfy its customer demand? Why? If demand is increased 50%, what is your two best solutions What should we do to maximine capacity of the current production system? 3. Given the production system of a company, for each machine they setup one time and run for one day demand. The manual operation, processing time and setup time are provided in the following table. Machine Setup Total time Daily Name of Operation time per unit Production operations operations Time (sec.) (sec.) (sec.) (sec.) Capacity Pick up the material from the pallet CD-300: center drill KA-350: chamfer Manual Order of time 1 1 0 0 2 7 80 200 3 9 95 150 4 KB-400: ream 9 85 175 5 KC-450: ream 10 78 300 6 NE-200 8 50 600 7 GR-101 5 0 0 8 SA-130 7 70 300 9 JI-500 10 90 600 10 HU-400 12 55 900 11 Wash, put in the pallet 20 0 0 Based on the customer demand, the required output of this system is 240 units per day. Moreover, the company operates 8 hours a day, there is one operator in this production system, and the walking time between two consecutive operations is two seconds, and between the last to the first operation is 3 seconds a) Fill in table above b) identify bottle neck c) Establish the standard operation routine sheet for the company produciton system as the form above d) Could the company satisfy its customer demand? Why? If demand is increased 50%, what is your two best solutions What should we do to maximine capacity of the current production system