Question

38)Incremental revenues: Select the correct one a. May increase or decrease when one course of action is selected over another. b. Cause revenues to remain

38)Incremental revenues:

Select the correct one

a. May increase or decrease when one course of action is selected over another. b. Cause revenues to remain steady. c. Always increase revenue when one course of action is selected over another. d. Always decrease revenue when one course of action is selected over another.

39) Which cost is not relevant in making financial decisions?

Select the correct one

All three are relevant. Incremental costs. Opportunity costs. Sunk costs.

40) The cost of draining sap out of a maple tree to manufacture maple syrup and maple sugar is an example of:

Select the correct one

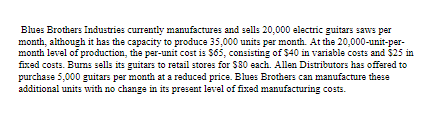

Joint costs. Sunk costs. After-split-off costs. Incremental costs. 41. Which of the following is not a relevant factor in Blues Brothers decision concerning whether to accept the special order from Allen?  Select the correct one

Select the correct one

a. The incremental cost of manufacturing an additional 5,000 guitars per month. b. Where and at what price Allen intends to sell the guitars. c. The opportunity cost involved in accepting Allen's order. d. The $65 average cost per unit to manufacture an electric guitar. 42. Assume that Allen Distributors offers to purchase the additional 5,000 guitars at a price of $47 per unit. If The Blues Brothers accepts this price, their' monthly gross profit on sales of electric guitars will:  Select the correct one Increase by $185,000. Decrease by $40,000. Decrease by $240,000. Increase by $35,000. 43. Using an incremental analysis approach, The Blues Brothers should consider accepting this special order only if the price per unit offered by Allen is at least:

Select the correct one Increase by $185,000. Decrease by $40,000. Decrease by $240,000. Increase by $35,000. 43. Using an incremental analysis approach, The Blues Brothers should consider accepting this special order only if the price per unit offered by Allen is at least:

Select the correct one

a. $20 b. $50 c. $40 d. $80 PLEASE ANSWER ALL THE QUESTIONS. I JUST NEED THE RIGHT ANSWER AND NOT EXPLANATION PLEASE

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started