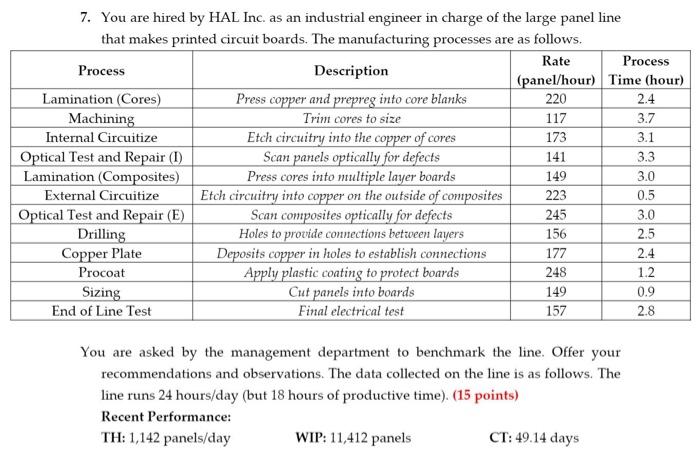

7. You are hired by HAL Inc. as an industrial engineer in charge of the large panel line that makes printed circuit boards. The manufacturing processes are as follows. Rate Process Process Description (panel/hour) Time (hour) Lamination (Cores) Press copper and prepreg into core blanks 220 2.4 Machining Trim cores to size 117 3.7 Internal Circuitize Etch circuitry into the copper of cores 173 3.1 Optical Test and Repair (1) Scan panels optically for defects 141 3.3 Lamination (Composites) Press cores into multiple layer boards 149 External Circuitize Etch circuitry into copper on the outside of composites 223 0.5 Optical Test and Repair (E) Scan composites optically for defects 245 3.0 Drilling Holes to provide connections between layers 156 2.5 Copper Plate Deposits copper in holes to establish connections 177 2.4 Procoat Apply plastic coating to protect boards 248 1.2 Sizing Cut panels into boards 149 0.9 End of Line Test Final electrical test 2.8 3.0 157 You are asked by the management department to benchmark the line. Offer your recommendations and observations. The data collected on the line is as follows. The line runs 24 hours/day (but 18 hours of productive time) (15 points) Recent Performance: TH: 1142 panels/day WIP: 11,412 panels CT: 49.14 days 7. You are hired by HAL Inc. as an industrial engineer in charge of the large panel line that makes printed circuit boards. The manufacturing processes are as follows. Rate Process Process Description (panel/hour) Time (hour) Lamination (Cores) Press copper and prepreg into core blanks 220 2.4 Machining Trim cores to size 117 3.7 Internal Circuitize Etch circuitry into the copper of cores 173 3.1 Optical Test and Repair (1) Scan panels optically for defects 141 3.3 Lamination (Composites) Press cores into multiple layer boards 149 External Circuitize Etch circuitry into copper on the outside of composites 223 0.5 Optical Test and Repair (E) Scan composites optically for defects 245 3.0 Drilling Holes to provide connections between layers 156 2.5 Copper Plate Deposits copper in holes to establish connections 177 2.4 Procoat Apply plastic coating to protect boards 248 1.2 Sizing Cut panels into boards 149 0.9 End of Line Test Final electrical test 2.8 3.0 157 You are asked by the management department to benchmark the line. Offer your recommendations and observations. The data collected on the line is as follows. The line runs 24 hours/day (but 18 hours of productive time) (15 points) Recent Performance: TH: 1142 panels/day WIP: 11,412 panels CT: 49.14 days