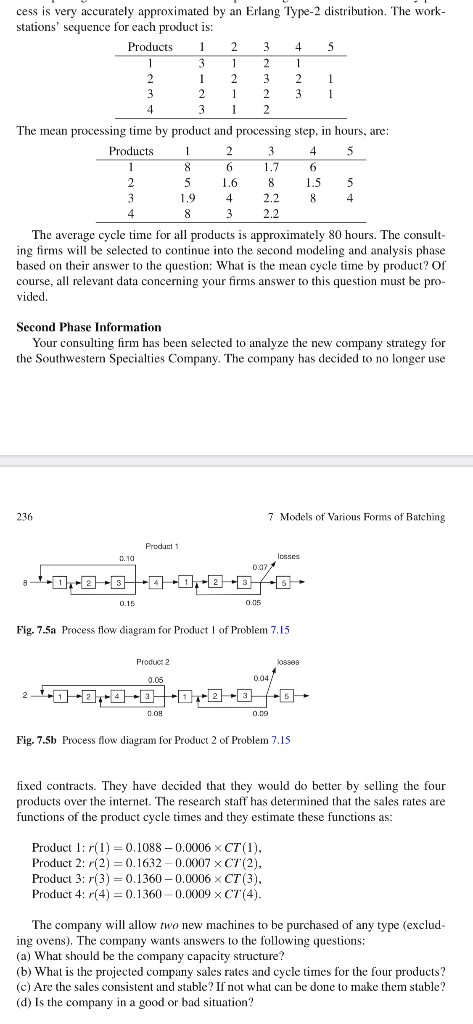

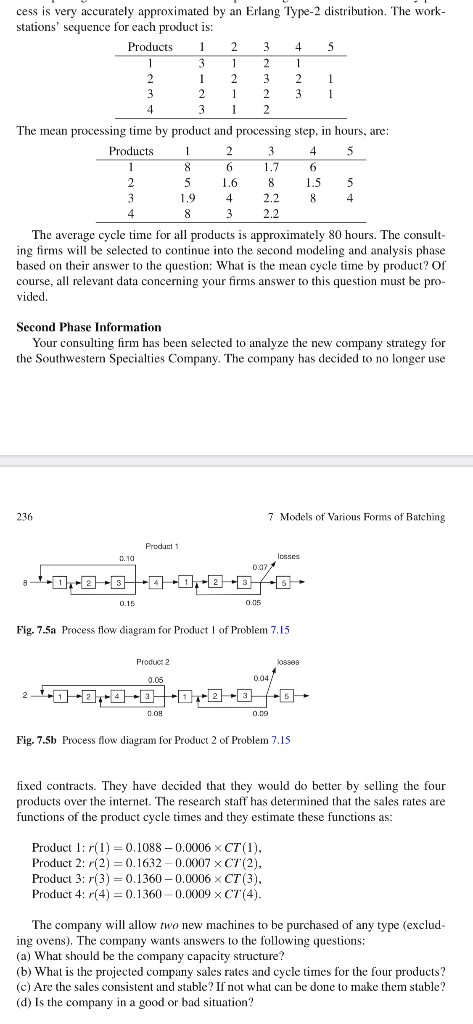

7.14. Team Project Problem. The Southwestern Specialties Company has a line of four products that they produce in their factory located in Houston, Texas, working 24 hours per day. The company is soliciting bids from consulting firms for the anal- ysis of their current and future factory performances. The company currently has contracts with several national retail companies, such as Wal-Mart, Kmart, and Tar- get, to produce specific quantities of each of their four products. The initial project phase is to develop a model of their current factory and develop cycle time estimates for each product. The second phase of the project will be to predict the impact of a new marketing strategy based on E-Commerce using the World-Wide-Web. Several consulting companies have been selected to perform the first phase of the project (current factory performance modeling) and the best among those will be selected Problems 235 for the future phase. Only after successfully demonstrating your consulting firms capabilities, will the company authorize the release to the consulting firm the nature of the second phase of the modeling and analysis project. First Phase Information The Southwestern Specialties Company's Houston factory consists of three workstations (called Workstations 1, 2 and 3). Workstation 3 is an oven heat- treatment facility. The four products take different routes through the three work- stations and have different numbers of processing steps. There currently are three machines in Workstation 1 and one machine each in Workstations 2 and 3. The machine (oven) in Workstation 3 has the capacity to process up to 4 units simulta- neously, but it is currently operated with a fixed batch size of 3 units. Engineering has spent considerable design and analysis time over the years to develop a process- ing procedure that allows all four of the products to be processed in the oven with the same time and temperature settings. Therefore, the factory operations personnel can form an oven batch from any combination of the four product types. Orders are released to the factory according to a Poisson process at a mean rate of 7.68 orders per day. The current distribution of order releases by product type is (20%, 30%, 25%, 25%) for Products, 1, 2, 3 and 4, respectively. Engineering has developed standard times for each of the processing steps for each product and these "mean" times are listed below. Their analysis has revealed the surprising fact that the distribution of processing times for each and every pro- cess is very accurately approximated by an Erlang Type-2 distribution. The work- stations' sequence for each product is: Products 1 2 3 4 5 1 3 1 2 1 2 1 2 3 2 1 3 2 1 2 3 1 4 3 1 2 The mean processing time by product and processing step, in hours, are: 1 2 3 4 5 Products 1 8 6 1.7 6 2 5 1.6 8 1.5 5 3 1.9 4 2.2 8 4 4 8 3 2.2 The average cycle time for all products is approximately 80 hours. The consult- ing firms will be selected to continue into the second modeling and analysis phase based on their answer to the question: What is the mean cycle time by product? Of course, all relevant data concerning your firms answer to this question must be pro- vided. Second Phase Information Your consulting firm has been selected to analyze the new company strategy for the Southwestern Specialties Company. The company has decided to no longer use cess is very accurately approximated by an Erlang Type-2 distribution. The work- stations' sequence for each product is: Products 1 2 3 4 5 1 3 1 2 1 2 1 2 3 2 1 3 2 1 2 3 1 4 3 1 2 The mean processing time by product and processing step, in hours, are: Products 1 2 3 4 5 1 8 6 1.7 6 2 5 1.6 8 1.5 5 3 1.9 4 2.2 8 4 4 8 3 2.2 The average cycle time for all products is approximately 80 hours. The consult- ing firms will be selected to continue into the second modeling and analysis phase based on their answer to the question: What is the mean cycle time by product? Of course, all relevant data concerning your firms answer to this question must be pro- vided. Second Phase Information Your consulting firm has been selected to analyze the new company strategy for the Southwestern Specialties Company. The company has decided to no longer use 236 7 Models of Various Forms of Batching Product 1 losses 0.08 0.09 Fig. 7.5b Process flow diagram for Product 2 of Problem 7.15 fixed contracts. They have decided that they would do better by selling the four products over the internet. The research staff has determined that the sales rates are functions of the product cycle times and they estimate these functions as: Product 1: r(1) = 0.1088 -0.0006 CT (1), Product 2: r(2) = 0.1632-0.0007 CT (2), Product 3: r(3) = 0.1360-0.0006 CT (3), Product 4: r(4) = 0.1360-0.0009 x CT (4). The company will allow two new machines to be purchased of any type (exclud- ing ovens). The company wants answers to the following questions: (a) What should be the company capacity structure? (b) What is the projected company sales rates and cycle times for the four products? (c) Are the sales consistent and stable? If not what can be done to make them stable? (d) Is the company in a good or bad situation? 0.10 2 0.07 08-6--0 +8+8=*4+0+*8*8*6* 0.15 0.05 Fig. 7.5a Process flow diagram for Product 1 of Problem 7.15 Product 2 losses 0.05 0.04/ +*+0+2+0+0] +0+2+0+0+ 7.14. Team Project Problem. The Southwestern Specialties Company has a line of four products that they produce in their factory located in Houston, Texas, working 24 hours per day. The company is soliciting bids from consulting firms for the anal- ysis of their current and future factory performances. The company currently has contracts with several national retail companies, such as Wal-Mart, Kmart, and Tar- get, to produce specific quantities of each of their four products. The initial project phase is to develop a model of their current factory and develop cycle time estimates for each product. The second phase of the project will be to predict the impact of a new marketing strategy based on E-Commerce using the World-Wide-Web. Several consulting companies have been selected to perform the first phase of the project (current factory performance modeling) and the best among those will be selected Problems 235 for the future phase. Only after successfully demonstrating your consulting firms capabilities, will the company authorize the release to the consulting firm the nature of the second phase of the modeling and analysis project. First Phase Information The Southwestern Specialties Company's Houston factory consists of three workstations (called Workstations 1, 2 and 3). Workstation 3 is an oven heat- treatment facility. The four products take different routes through the three work- stations and have different numbers of processing steps. There currently are three machines in Workstation 1 and one machine each in Workstations 2 and 3. The machine (oven) in Workstation 3 has the capacity to process up to 4 units simulta- neously, but it is currently operated with a fixed batch size of 3 units. Engineering has spent considerable design and analysis time over the years to develop a process- ing procedure that allows all four of the products to be processed in the oven with the same time and temperature settings. Therefore, the factory operations personnel can form an oven batch from any combination of the four product types. Orders are released to the factory according to a Poisson process at a mean rate of 7.68 orders per day. The current distribution of order releases by product type is (20%, 30%, 25%, 25%) for Products, 1, 2, 3 and 4, respectively. Engineering has developed standard times for each of the processing steps for each product and these "mean" times are listed below. Their analysis has revealed the surprising fact that the distribution of processing times for each and every pro- cess is very accurately approximated by an Erlang Type-2 distribution. The work- stations' sequence for each product is: Products 1 2 3 4 5 1 3 1 2 1 2 1 2 3 2 1 3 2 1 2 3 1 4 3 1 2 The mean processing time by product and processing step, in hours, are: 1 2 3 4 5 Products 1 8 6 1.7 6 2 5 1.6 8 1.5 5 3 1.9 4 2.2 8 4 4 8 3 2.2 The average cycle time for all products is approximately 80 hours. The consult- ing firms will be selected to continue into the second modeling and analysis phase based on their answer to the question: What is the mean cycle time by product? Of course, all relevant data concerning your firms answer to this question must be pro- vided. Second Phase Information Your consulting firm has been selected to analyze the new company strategy for the Southwestern Specialties Company. The company has decided to no longer use cess is very accurately approximated by an Erlang Type-2 distribution. The work- stations' sequence for each product is: Products 1 2 3 4 5 1 3 1 2 1 2 1 2 3 2 1 3 2 1 2 3 1 4 3 1 2 The mean processing time by product and processing step, in hours, are: Products 1 2 3 4 5 1 8 6 1.7 6 2 5 1.6 8 1.5 5 3 1.9 4 2.2 8 4 4 8 3 2.2 The average cycle time for all products is approximately 80 hours. The consult- ing firms will be selected to continue into the second modeling and analysis phase based on their answer to the question: What is the mean cycle time by product? Of course, all relevant data concerning your firms answer to this question must be pro- vided. Second Phase Information Your consulting firm has been selected to analyze the new company strategy for the Southwestern Specialties Company. The company has decided to no longer use 236 7 Models of Various Forms of Batching Product 1 losses 0.08 0.09 Fig. 7.5b Process flow diagram for Product 2 of Problem 7.15 fixed contracts. They have decided that they would do better by selling the four products over the internet. The research staff has determined that the sales rates are functions of the product cycle times and they estimate these functions as: Product 1: r(1) = 0.1088 -0.0006 CT (1), Product 2: r(2) = 0.1632-0.0007 CT (2), Product 3: r(3) = 0.1360-0.0006 CT (3), Product 4: r(4) = 0.1360-0.0009 x CT (4). The company will allow two new machines to be purchased of any type (exclud- ing ovens). The company wants answers to the following questions: (a) What should be the company capacity structure? (b) What is the projected company sales rates and cycle times for the four products? (c) Are the sales consistent and stable? If not what can be done to make them stable? (d) Is the company in a good or bad situation? 0.10 2 0.07 08-6--0 +8+8=*4+0+*8*8*6* 0.15 0.05 Fig. 7.5a Process flow diagram for Product 1 of Problem 7.15 Product 2 losses 0.05 0.04/ +*+0+2+0+0] +0+2+0+0+