Answered step by step

Verified Expert Solution

Question

1 Approved Answer

a ) Data on the process Feed: - T = 8 0 F - P = 3 7 psia Flash: - T m = 2

a Data on the process

Feed:

psia

Flash:

psia

Absorber:

number of theoretical stages

number of real stages

pressure at the top and at the bottom psia

Distillation column:

number of theoretical trays

number of real trays

psia

monochlorobenzene from the top lbmo

Cooler:

Products:

monochlorobenzene lbmo

Thermodynamic model: Wilson Virial b Data for the economic evaluation

Calculation of the grass roots cost of the plant

Purchase cost of equipment in base conditions

A:characteristic variable of the equipment

The coefficients provided in the table refer to year & For the calculation of costs

related to nowadays please use M&S equal to

For the calculation of the exchange areas the following assumptions should be considered:

;

;

;

;

service fluid for the condenser and for the heat exchanger : cooling water entering at and

exiting at Both the heat exchangers are countercurrent;

service fluid for the heat exchanger : saturated steam at atm; service fluid for the Kettle reboiler: saturated steam at atm

For the calculation of the volumes of the columns the following assumptions should be considered:

vapor speed along the column: ;

Assume as purchase costs for the flash chamber other vessels, for accumulation and storage and for

the pumps $ and S respectively.

Installation costs

Perforated trays

mumber trays; ;

:

Other units:

For all the units except for the pumps and the Kettle reboiler: For the pumps:

and For the Kettle reboiler: and

with between and Process for the separation of monochlorobenzene: design and economic evaluation

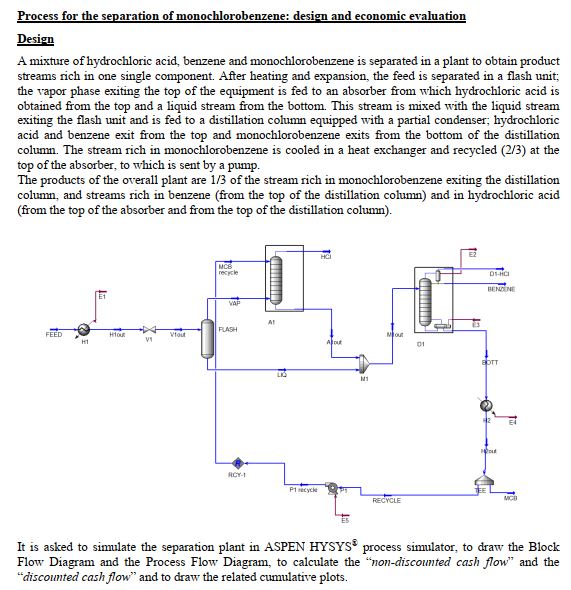

Design

A mixture of hydrochloric acid, benzene and monochlorobenzene is separated in a plant to obtain product

streams rich in one single component. After heating and expansion, the feed is separated in a flash unit;

the vapor phase exiting the top of the equipment is fed to an absorber from which hydrochloric acid is

obtained from the top and a liquid stream from the bottom. This stream is mixed with the liquid stream

exiting the flash unit and is fed to a distillation column equipped with a partial condenser; hydrochloric

acid and benzene exit from the top and monochlorobenzene exits from the bottom of the distillation

column. The stream rich in monochlorobenzene is cooled in a heat exchanger and recycled at the

top of the absorber to which is sent by a pump.

The products of the overall plant are of the stream rich in monochlorobenzene exiting the distillation

column, and streams rich in benzene from the top of the distillation column and in hydrochloric acid

from the top of the absorber and from the top of the distillation column

It is asked to simulate the separation plant in ASPEN HYSYS process simulator, to draw the Block

Flow Diagram and the Process Flow Diagram, to calculate the "nondiscounted cash flow" and the

"discounted cash flow" and to draw the related cumulative plots.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started