Question

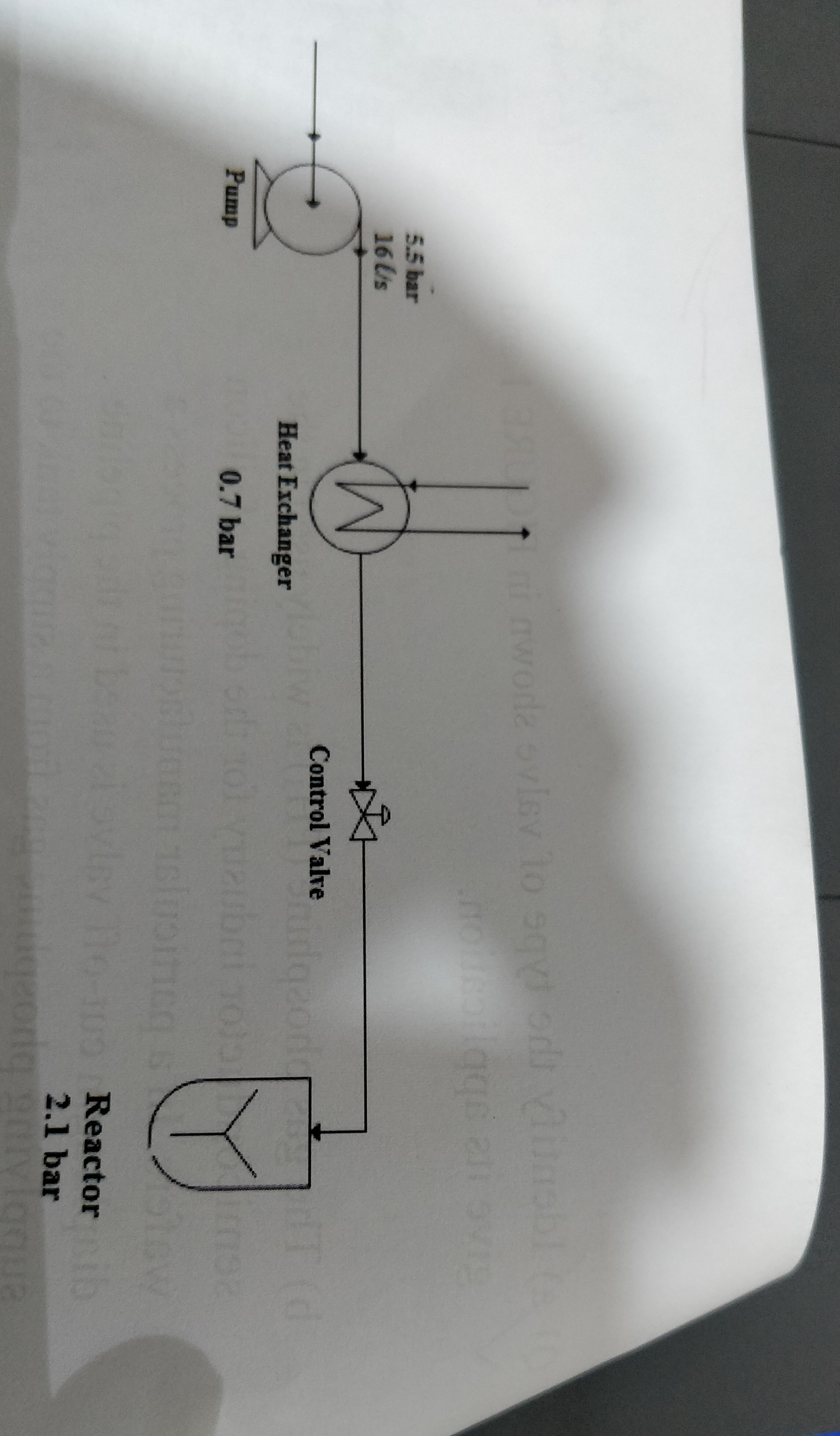

A liquid chemical, which has a density of 600 kg/m3 , is pumped at 5.5 bar gauge at a nominal rate of 16 litres per

A liquid chemical, which has a density of 600 kg/m3 , is pumped at 5.5 bar gauge at a nominal rate of 16 litres per second. However the design must permit the flow rate to vary over the range of 8 to 25 litres per second. The design must also allow for a pressure loss of 0.7 bar across the heat exchanger and the pressure in the reactor must be kept at 2.1 bar. It can be assumed that the flow is turbulent and non-choked.

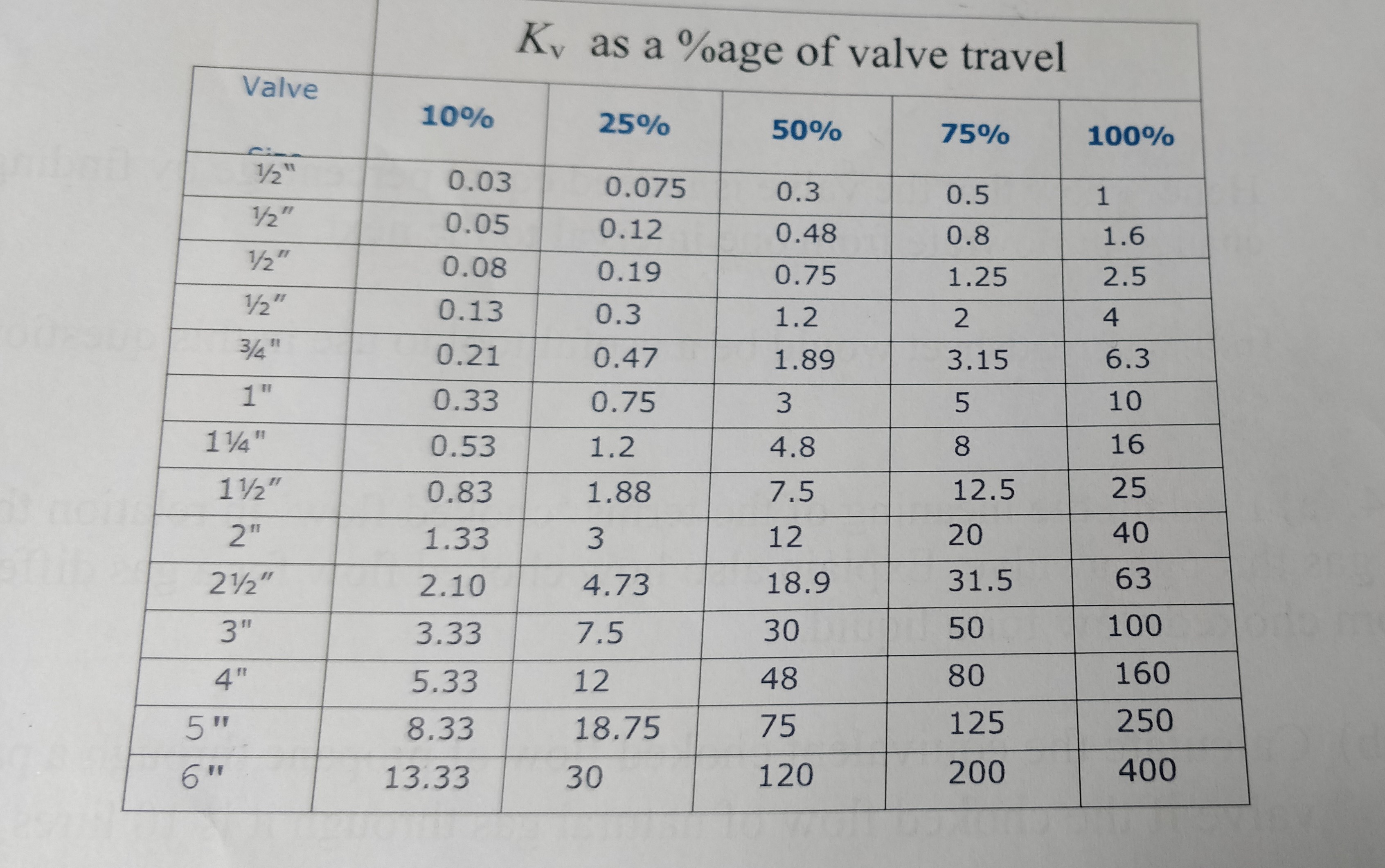

Suppose the globe valve chosen has the size-Kv values shown in the table below.

(i) Use the table to determine the required valve size for a nominal flow of 16 litres per second. Note: ?? = ???( ??/ ?)

where qv =volumetric flow through the valve in m3/hr, ?? = pressure drop, d = relative density

(ii) Check to see if this valve size is suitable over the range of the full flow-rate {8 to 25 litres per second} and amend your sizing if necessary

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started